New Fabrication Technology for Electronic Transport Layers in Perovskite Solar Cells

New Fabrication Technology for Perovskite Solar Cells

Sumitomo Heavy Industries, headquartered in Shinagawa, Tokyo, has made significant strides in the development of advanced solar technology. The company has successfully created a novel fabrication process for the electronic transport layers crucial to perovskite solar cells, which are increasingly seen as next-generation energy solutions. Using cost-effective materials and environmentally friendly procedures, this new technology is set to transform the solar energy landscape.

Understanding Electronic Transport Layers

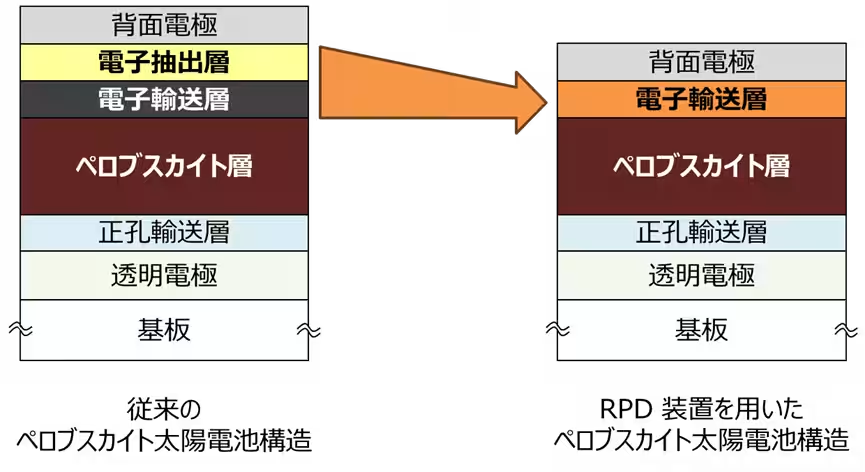

Within a perovskite solar cell, the electronic transport layer (ETL) plays a pivotal role. It is a thin film formulated either above or below the active layer that allows electrons generated in the perovskite layer to flow seamlessly towards the electrodes. Designing this layer to receive electrons efficiently from the perovskite layer is crucial, as is ensuring that it does not damage the sensitive perovskite when deposited.

Traditional deposition methods are inadequate for creating these layers as they often require high-energy particles and elevated temperatures, which can degrade the perovskite compound. As a result, many manufacturers are exploring chemical deposition methods. However, these approaches often utilize costly materials and are limited by issues regarding low scalability and hazardous properties of the precursor gases involved.

Innovative RPD Technology

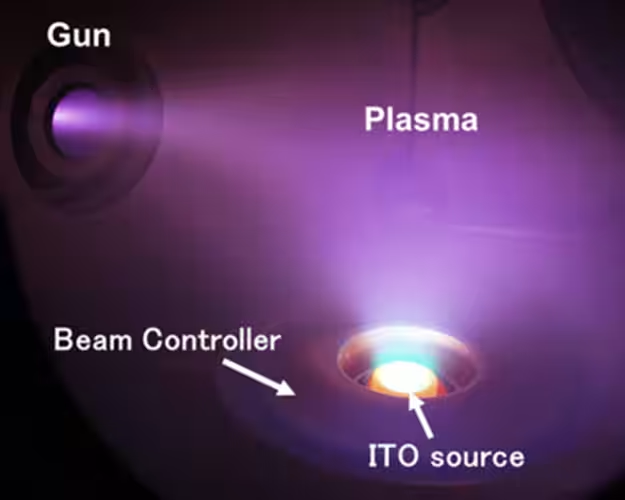

To address these challenges, Sumitomo Heavy Industries' Technical Research Institute has successfully developed a new methodology utilizing their proprietary Reactive Plasma Deposition (RPD) technique. This approach allows for the formation of pure tin oxide (SnO2) layers suitable for use in perovskite solar cells.

RPD is a variation of physical vapor deposition (PVD) characterized by its low-temperature and low-damage properties, along with its ability to be applied rapidly over large surfaces. Moreover, it employs safer gases, resulting in a minimal environmental impact. When applied to the deposition of SnO2, this method produces a layer with excellent conductivity suitable for the ETL function.

An essential advantage of the RPD technology is that it enables the creation of SnO2 layers that possess an optimal level of insulation, allowing them to function effectively as electronic transport layers without excessive conductivity, a challenge faced in previous methods. This advancement not only promises to enhance the manufacturing process but also significantly reduces production costs.

Advantages and Future Aspirations

The new technology allows for SnO2 layers to be produced at speeds over 200 times faster than what current methods can achieve, while also lowering costs to less than 1/200th of those existing techniques. Additionally, the RPD technique has already been validated in applications like transparent conductive films for solar cells, flat panel displays, and organic EL panels, which paves the way for the integrated continuous processing of ETLs and transparent conducting layers.

As the demand for efficient, sustainable energy solutions grows, Sumitomo Heavy Industries aims to advance the mass production application of this innovative deposition technology further. The company's commitment is closely aligned with the global push toward carbon neutrality, supporting the broader adoption of perovskite solar cells.

Conclusion

Perovskite solar cells represent an exciting frontier in photovoltaic technology, combining high efficiency with lower production costs and versatile design options. The innovative developments by Sumitomo Heavy Industries signal a promising future as these technologies become integrated into our renewable energy systems, contributing to environmental sustainability and energy access worldwide.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.