Idein and CTC Collaborate to Develop Edge AI Solutions for Manufacturing Industry

Idein and CTC Unite to Revolutionize Manufacturing with Edge AI Solutions

In a significant move to advance the manufacturing industry, Idein Inc. has announced its collaboration with Itochu Techno-Solutions Corporation (CTC) to develop innovative Edge AI solutions tailored for manufacturing. With Idein as a leader in the Edge AI platform market, operating the industry-preferred platform "Actcast," this partnership marks an essential step towards optimizing operational efficiency in manufacturing environments.

Idein, headquartered in Chiyoda, Tokyo, has consistently held the number one market share domestically for four consecutive years. The company's expertise lies in streamlining manufacturing operations through advanced technology. Alongside CTC’s robust data utilization services, the partnership aims to combat prevalent challenges such as disparate management of IoT devices and difficulties in capitalizing on operational data.

The Need for Edge AI in Manufacturing

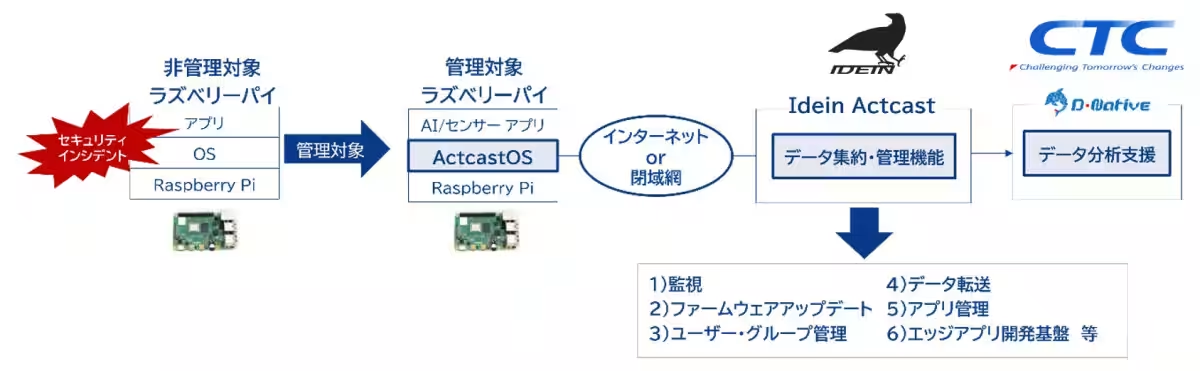

The recent surge in accessible AI cameras and sensors has catalyzed the IoT transformation in factories. With the affordability of compact general-purpose devices, manufacturing companies are increasingly integrating them to monitor equipment activity and assess product quality. However, challenges abound; many production facilities suffer from fragmented device management, leading to inconsistent security settings and neglect of software updates. This disparity calls for a unified approach to data collection and management to improve quality control and operational efficiency.

The Edge AI solution that Idein and CTC are developing will seamlessly integrate Idein’s "Actcast" platform with CTC’s "D-Native" data utilization services. This integration aims to provide secure and efficient data management from various IoT sensors, allowing factories to proactively address issues related to quality variations and operational inefficiencies.

Key Features of the New Edge AI Solution

1. Centralized Management of IoT Devices: The partnership will enable real-time management of multiple Raspberry Pi devices deployed across factories. This centralized oversight allows for remote configuration updates and software maintenance, enhancing security and reducing operational workload.

2. Data Accumulation and Visualization: CTC’s D-Native service will aid in accumulating critical data from IoT sensors—including temperature, humidity, dimensions, weight, and energy consumption—thereby facilitating comprehensive analysis and visualization.[1]

3. Improving Quality Control Processes: By leveraging real-time data insights, manufacturers can swiftly identify and rectify anomalies in production processes, leading to improved product quality and operational protocols.

4. Development Support for Customized Solutions: CTC can assist in developing custom applications aimed at optimizing tasks and automating quality checks on Raspberry Pi devices, further promoting on-site operational enhancements.

A Legacy of Collaboration

This partnership is built on a foundation of previous collaborations between Idein and CTC, which have included the development of AI temperature detection devices and analytic solutions utilizing edge AI for manufacturing and retail. The companies are committed to evolving their collaborative efforts to employ edge computing solutions across various applications, including the control of industrial robots utilized in processes such as painting and assembly.

Actcast: The Core of Edge AI Technology

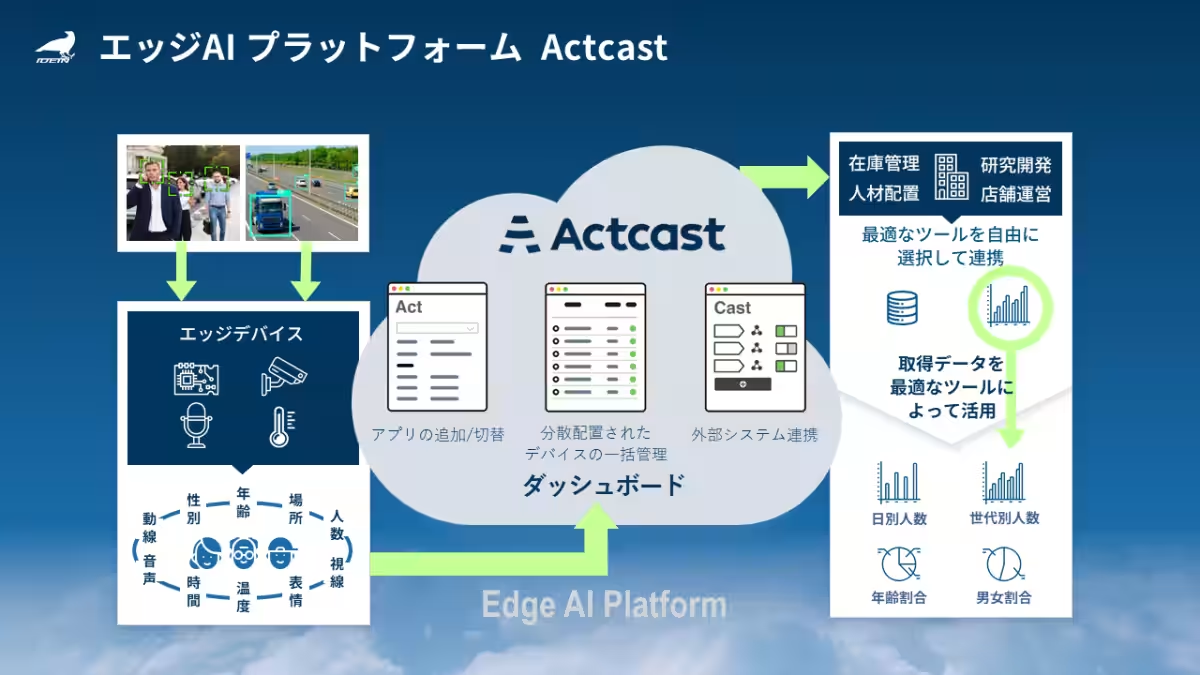

The Actcast platform enables the rapid, large-scale deployment of AI solutions, providing essential infrastructure for developers. It features a variety of sensing devices, which collect and utilize information across physical spaces. Actcast supports the management of multiple devices remotely, boasting an impressive record of over 16,000 units across various industries, and is home to a growing ecosystem of over 170 partner companies.

Additionally, Actcast ensures data privacy by minimizing the information sent to the cloud, focusing only on essential data. This means that manufacturers can implement advanced AI analytics using affordable, compact devices, significantly lowering costs.

The Future of AI and IoT in Manufacturing

Idein, through its cutting-edge technology, aims to democratize AI and IoT systems for manufacturing sectors. With a mission to make real-world information manageable through software, Idein has earned recognition from notable entities, including the Japanese Ministry of Economy, Trade, and Industry, and is part of esteemed partnership programs with global technology giants like Arm and NVIDIA.

As the partnership between Idein and CTC unfolds, it is expected that their collective efforts will not only enhance operational efficiencies but will also play a crucial role in advancing digital transformation (DX) initiatives across the manufacturing industry.

Originally reported on Actcast insights regarding market shares and opportunities for edge AI solutions. Future forecasts for 2025 indicate significant growth and innovation potentials.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.