HACARUS Unveils AI-Powered Inspection Solution for Food Packaging

HACARUS Launches AI-Powered Appearance Inspection Solution for Food Packaging

In a significant leap forward for the food manufacturing industry, HACARUS Co., based in Kyoto, Japan, has unveiled its latest innovation: an AI-driven appearance inspection solution tailored for food packaging. This new technology aims to streamline and enhance the quality inspection process in food production, addressing the ongoing challenges faced by manufacturers.

Background

Despite advancements in technology, many food manufacturing and packaging facilities still rely heavily on manual visual inspections, a method that is both time-consuming and labor-intensive. This dependence can lead to inconsistencies in inspection accuracy, issues of workforce shortages, and variability in the quality of inspections performed.

Traditional inspection methods, including costly X-ray systems, often present high barriers to entry for small and medium-sized food manufacturers due to their limited versatility and steep costs. In response to these pressing challenges, HACARUS is introducing a cost-effective inspection solution that leverages image recognition AI to accelerate the digital transformation (DX) of food manufacturing processes.

Solution Features

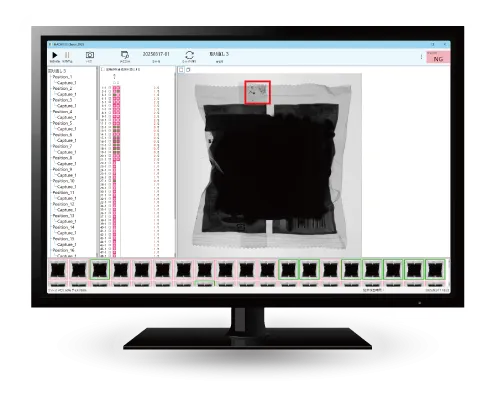

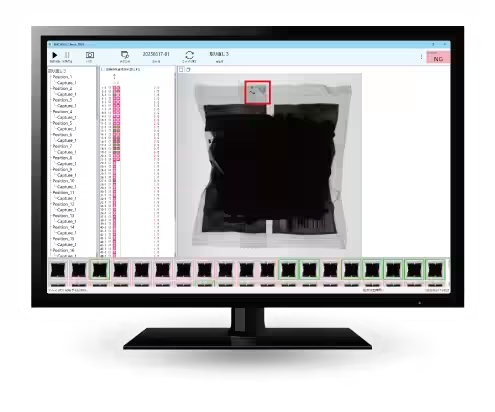

This new inspection solution is rooted in HACARUS's extensive experience and expertise in manufacturing and artificial intelligence, specially optimized for the food sector. Key features include:

- - Minimal Training Requirements: Unlike conventional AI systems that necessitate a large collection of defective images for training, this solution can commence learning with only a few images of good products. This minimizes the setup burden and allows for rapid implementation.

- - Dual Tuning for Continuous Improvement: Post-implementation, the system can learn from annotated data of both defective and good products, striking a balance between preventing oversights and reducing false positives. This ensures ongoing improvement in inspection accuracy in real-world settings.

- - Adaptability to Various Food Products: The technology is capable of inspecting diverse packaging types, including bags, pouches, and trays, effectively identifying a wide range of defects such as packaging faults, foreign material contamination, and shape irregularities.

- - Integrated Hardware and Software Proposal: HACARUS offers a comprehensive solution that optimally designs the entire inspection system, including conveyor devices, lighting, and cameras, tailored to fit the unique needs of each customer’s inspection process.

Potential Applications

This inspection solution can be deployed in several areas within the food production environment:

- - Packaging Inspection: Assessing for misalignment, tears, seal failures, and contamination to extract non-compliant products.

- - Foreign Matter Detection: Automatically identifying any foreign objects mixed in with the product and classifying them as anomalies.

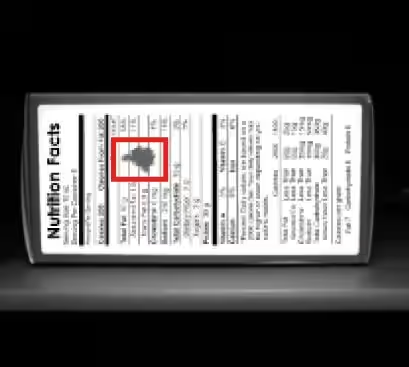

- - Label Printing Inspection: Evaluating labels and printed information for defects like smudged text, missing elements, misalignment, or inaccuracies.

- - Shape Defect Detection: Monitoring for irregularities such as cracks, chips, swellings, or deformations in product shapes to ensure quality.

Future Prospects

With the rollout of this innovative solution, HACARUS aims to promote standardization and efficiency of quality inspections within the food industry, contributing to increased sustainability in inspection processes. Future enhancements may include improved process feedback mechanisms for on-site staff, connectivity with tracing systems, and additional features that enhance the practical utility of AI in everyday operations.

For more in-depth information on HACARUS's offerings, visit their product introduction page here.

About HACARUS

HACARUS stands committed to its mission of 'Creating the Future for Innovators through Next-Generation Measurement Solutions.' Since its establishment in January 2014, the company has been dedicated to solving significant challenges faced by numerous enterprises through AI solutions that require minimal data inputs. By combining their unique technological prowess with practical operational expertise, HACARUS aims to streamline processes and facilitate the coexistence of humans and AI in the future of work.

Headquarters: 8th Floor, Oike Building, 206 Takamiya-cho, Nakagyo-ku, Kyoto, Japan

Founded: January 2014

CEO: Takashi Seta

Website: HACARUS

Press Inquiry: [email protected] (Public Relations)

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.