BambuLab H2D: The Precision 3D Printer & Laser Cutter Combination

BambuLab H2D: The Future of 3D Printing and Laser Cutting

In the realm of advanced manufacturing technology, BambuLab is making waves with the introduction of its latest product, the H2D 3D Printer. Set to begin pre-orders on April 22, 2025, by Sunstella Inc., this state-of-the-art FDM/FFF 3D printer not only promises exceptional precision but also versatile functionality as a laser cutter. Let's dive deep into what makes the H2D a remarkable addition to the world of fabrication.

Product Overview

The H2D printer stands out for its unparalleled minimum operational precision of 50μm, which is over ten times more accurate than traditional FDM/FFF printers. This level of precision allows for reliable reproduction across all phases of production, from prototyping to mass manufacturing, minimizing assembly errors and wobbliness between parts.

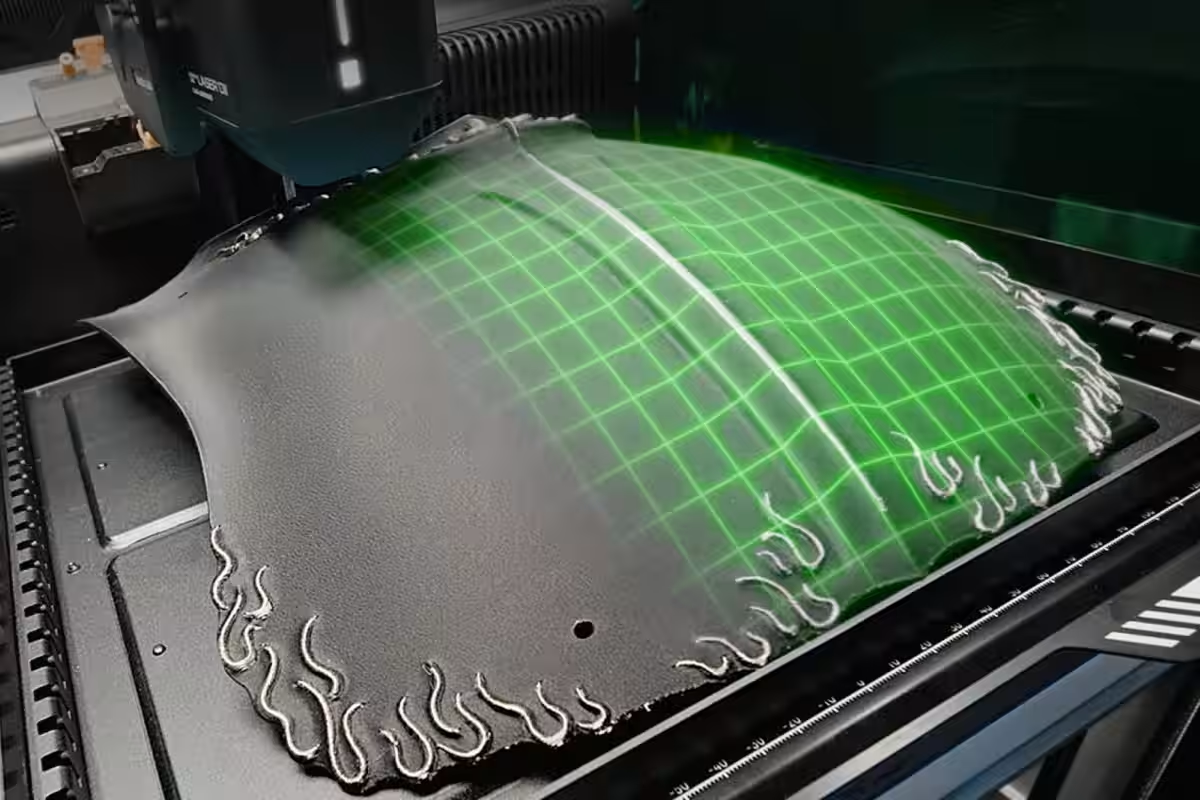

One of the highlights of the H2D is its dual nozzle design, which supports multi-material and multi-color printing, paired with a generous build area suitable for both prototypes and end-use products. This flexibility is complemented by the option of adding the latest laser cutting module, pen plotter, and cutting plotter functionalities, truly turning the H2D into an all-in-one digital fabrication hub.

Pricing and Availability

For those eager to get their hands on the H2D, here’s a breakdown of the prices and estimated release dates:

| SKU | Product Name | Price (Tax Included) | Estimated Arrival |

|---|---|---|---|

| ----- | ------ | ---- | ----- |

| PF003-D-JP | H2D Printer | ¥345,800 | June - July 2025 |

| PF003-D+SA007-JP | H2D AMS Combo | ¥363,455 | Early May 2025 |

| PF003-M+SA007+SL001-JP | H2D Laser Full Combo 10W | ¥495,600 | Early May 2025 |

| PF003-M+SA007+SL002-JP | H2D Laser Full Combo 40W | ¥598,600 | June - July 2025 |

| SA007 | AMS 2 Pro | ¥64,800 | Early May 2025 |

| SA008-JP | AMS HT | ¥25,800 | Late May 2025 |

Key Features of the H2D Printer

Exceptional Precision

Thanks to an advanced vision encoder plate and optical measurement technology with a resolution of 5μm, the H2D achieves a reliable operational precision of 50μm across its entire workspace, significantly enhancing quality over previous models when used with the vision encoder.

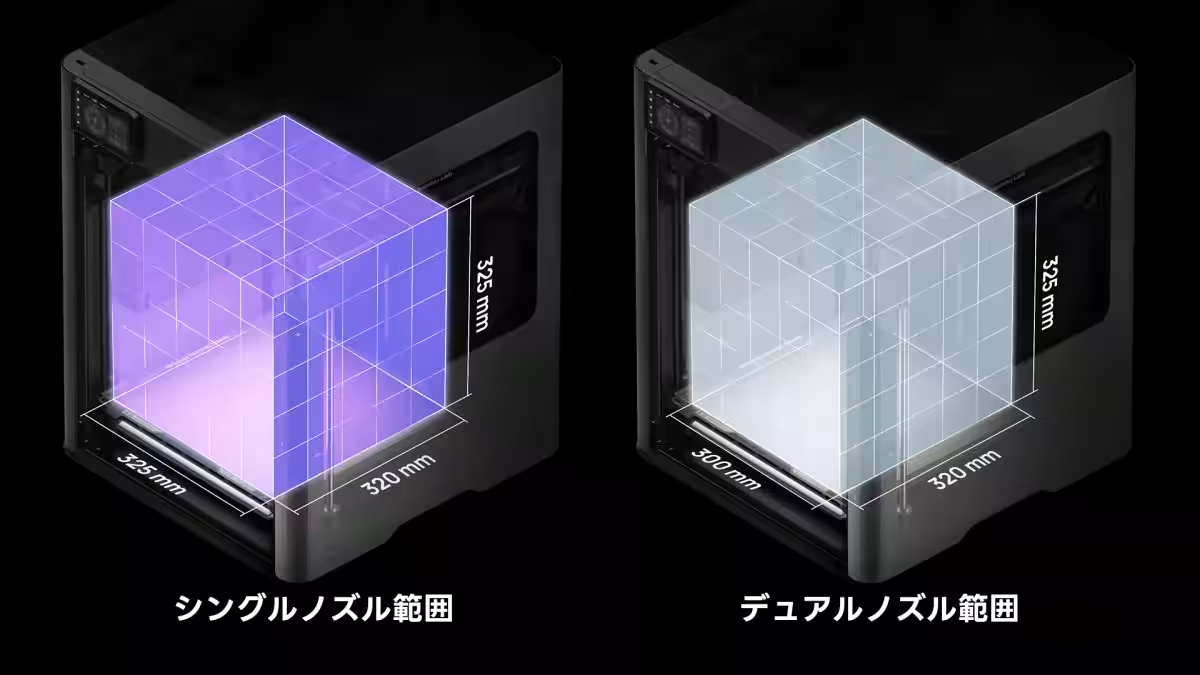

Spacious Build Area

With a maximum printing capacity of 350 x 320 x 325 mm, the H2D enables users to tackle large projects effortlessly, whether it’s for laser engraving on sizable objects or printing oversize models. This opens new avenues for creative exploration.

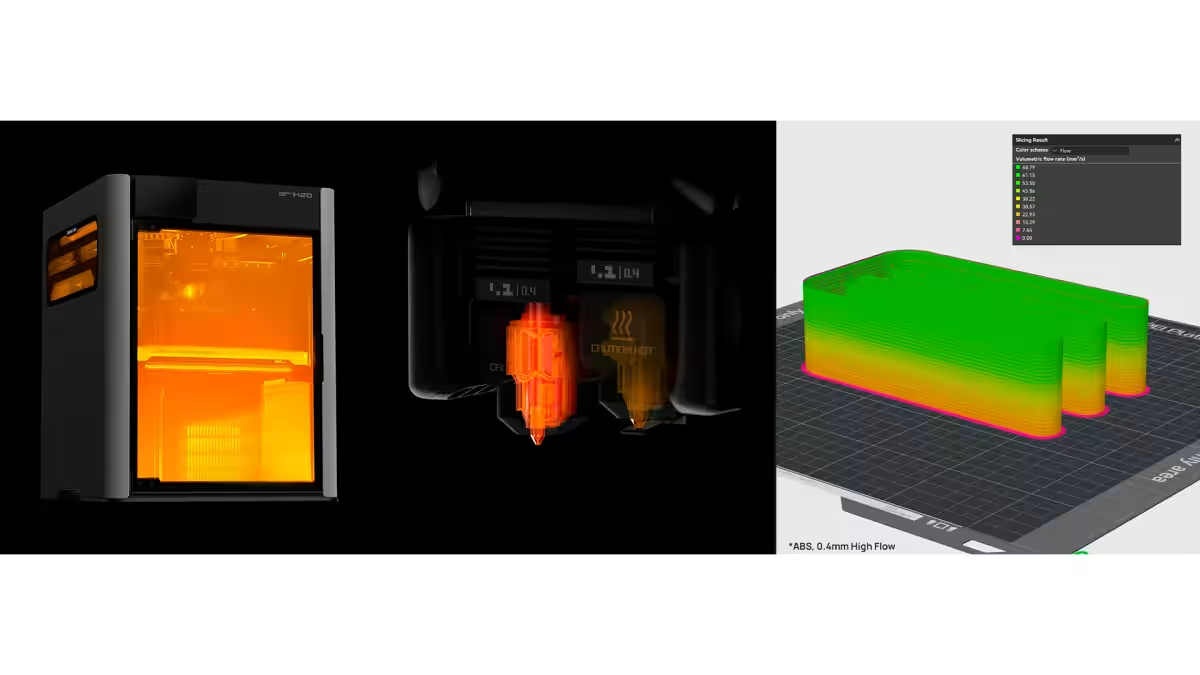

Fast Production of Various Materials

The printer supports high-speed manufacturing of a range of materials, including advanced polymers, with a maximum hotend temperature of 350℃ and heated chamber temperature of 65℃. Featuring a printing speed increase of 75% compared to earlier models, the H2D is optimized for efficiency while handling both flexible and rigid materials simultaneously.

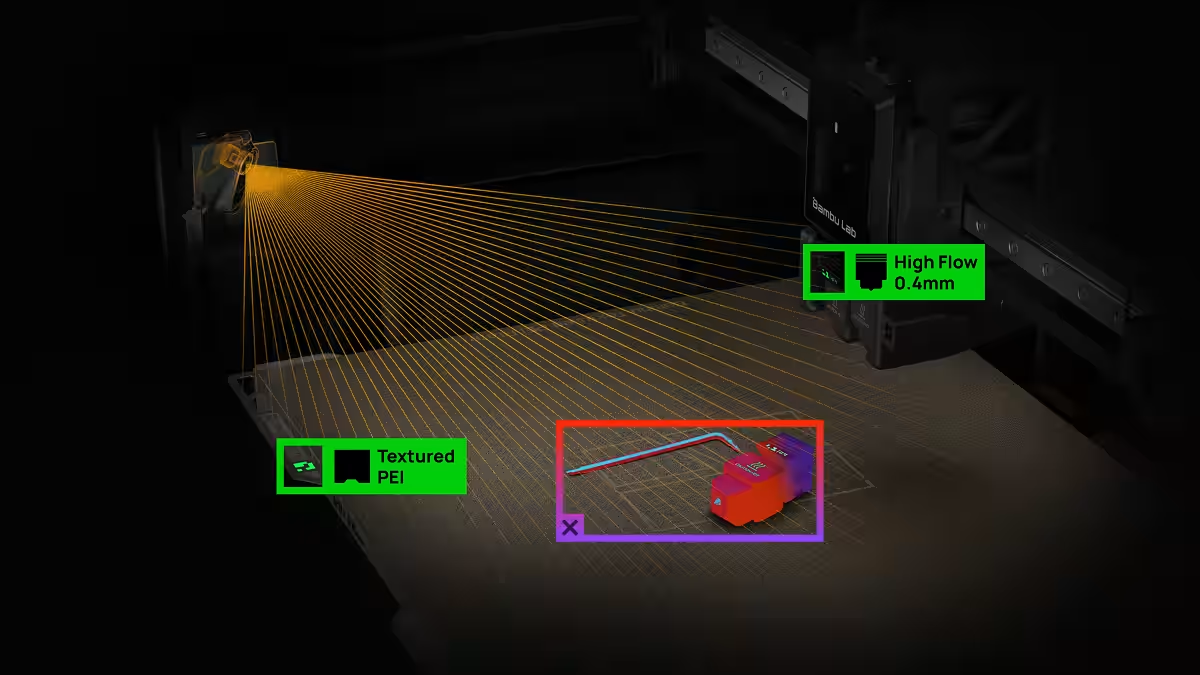

Intelligent Monitoring and Optimization

Equipped with four cameras and 36 sensors, the H2D ensures quality control with micron-level measurement accuracy and real-time diagnostics. This system provides pre-flight checks to detect abnormalities before production starts, enhancing chances of successful prints.

Additional Benefits from Sunstella

Purchasing through Sunstella Inc. not only guarantees access to the H2D but also includes exclusive offers such as the BambuStudio User Guide, designed to enhance user understanding of the slicing software. Sunstella ensures robust support and flexibility with its dedicated in-house stock, making prompt service possible even during unexpected shortages.

Furthermore, the Premium Warranty Service allows for quick exchanges on defective machines, ensuring minimal downtime with a commitment to user satisfaction.

Experience the H2D First-Hand

Sunstella is also hosting an experience event in Tokyo, offering potential users a chance to interact with the H2D in person. Details regarding the location and date are currently being finalized.

In conclusion, the BambuLab H2D 3D Printer is a game-changer in the 3D printing industry, catering to professionals and hobbyists alike, through its unmatched precision, extensive capabilities, and comprehensive support structure. As it prepares for launch, it could very well redefine what's possible in digital fabrication.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.