FLIR Launches Advanced Air Leak Detection Camera for Energy Savings

FLIR Launches New Air Leak Detection Camera

In the quest for energy efficiency, FLIR Systems has introduced its latest air leak detection camera, the FLIR Si1-LD-JP, specifically designed for compressed air systems. This innovative product features advanced technologies such as noise-canceling capabilities, automatic frequency adjustments, and enhanced detection ranges, all aimed at improving the identification of air leaks in industrial environments.

The launch of the FLIR Si1-LD-JP coincides with a promotional campaign, offering the camera for a limited-time price of 999,000 JPY until the end of September 2025. This initiative aligns with the company's mission to empower manufacturing industries to optimize energy consumption and significantly reduce operational costs associated with wasted compressed air. Studies suggest that approximately 20-30% of a typical factory's electricity costs are linked to air usage, making the detection and elimination of unnecessary air leaks an essential step towards operational efficiency.

The Importance of Air Leak Detection

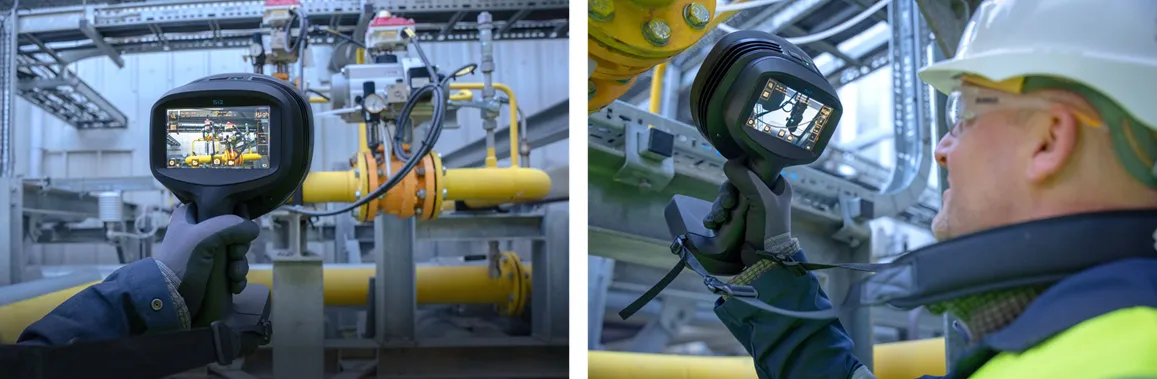

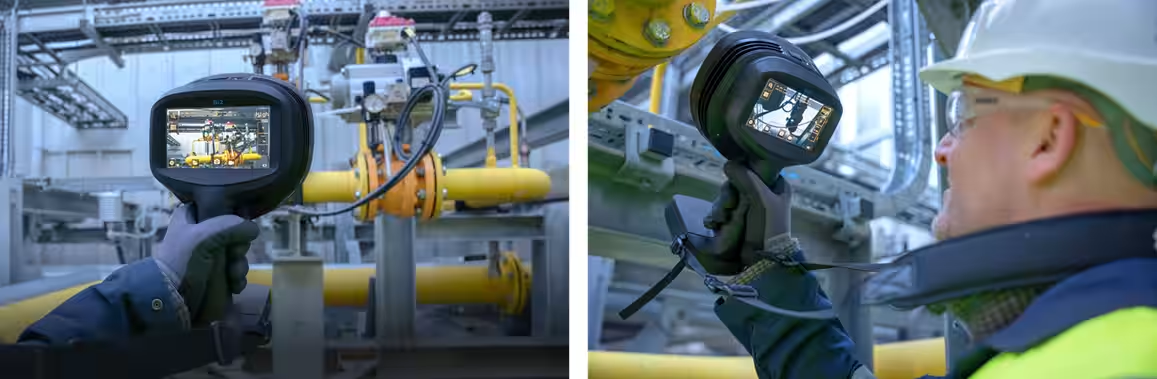

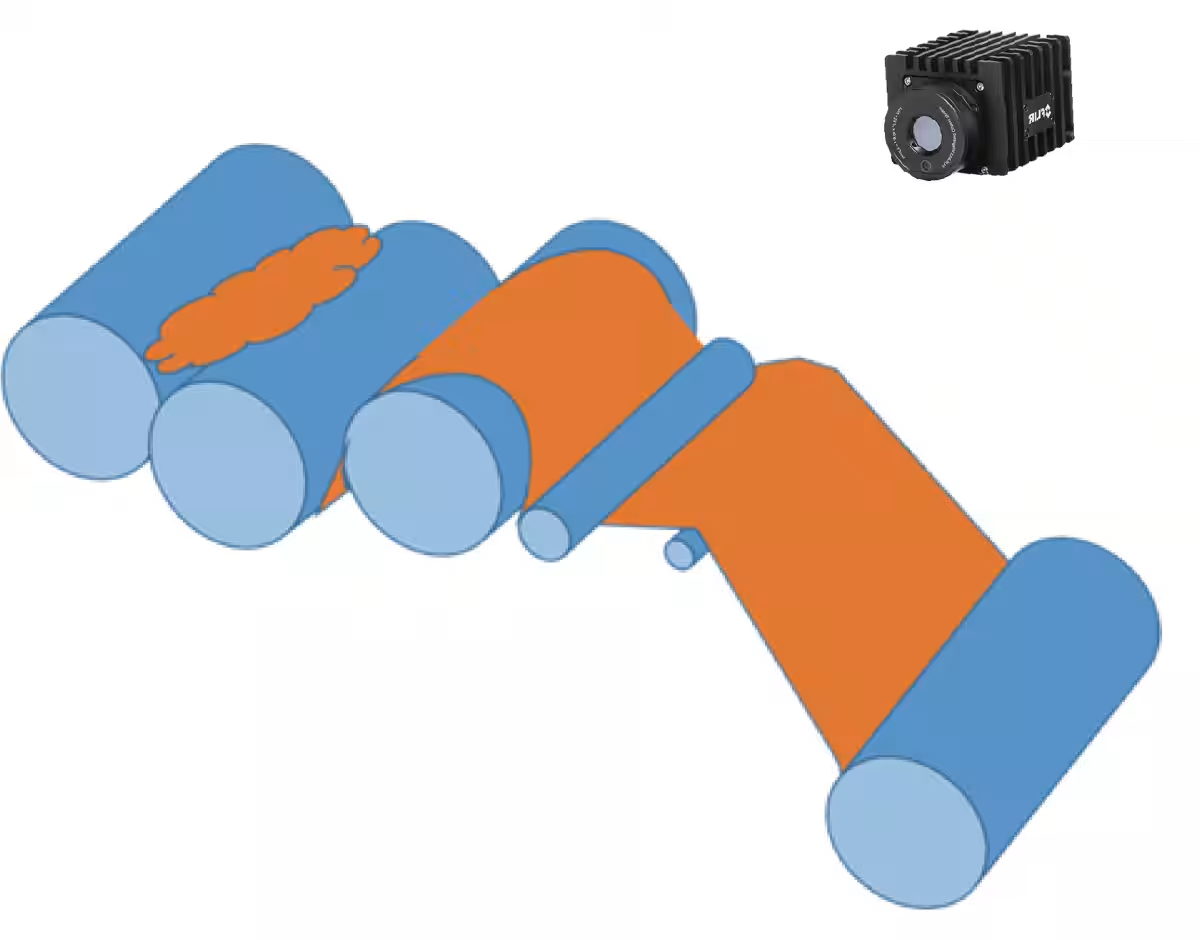

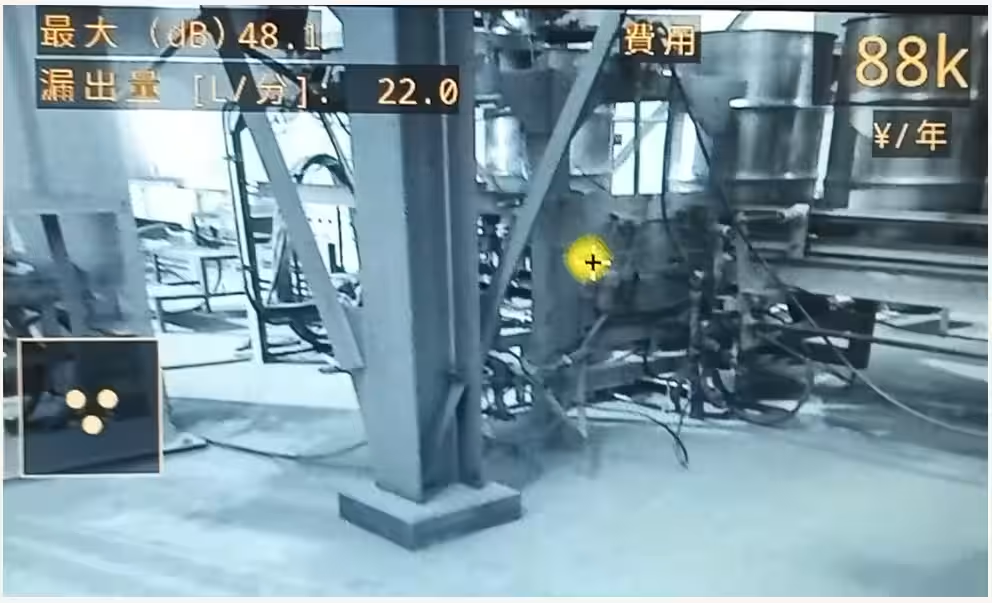

Many manufacturers struggle to pinpoint the exact locations and volumes of air leaks within extensive factory settings, often resulting in unresolved inefficiencies. The FLIR Si2-LD serves as a groundbreaking tool, enabling users to visualize air leaks with ease. By simply pointing the camera's lens and microphone at the target equipment, users can see color-marked leak sites on a display screen that also illustrates the volume of air loss in real-time.

Key Features of the FLIR Si2-LD

1. Precision Leak Location:

Equipped with 124 high-performance microphones, this model can accurately identify leak locations over broad areas, even amid operational noise, as it measures ultrasonic frequencies beyond the audible range.

2. Real-time Cost Calculation:

The camera automatically calculates loss costs based on the operational conditions, providing essential data for reducing costs associated with leakages.

3. Noise-Cancellation Technology:

Utilizing FLIR's proprietary noise-canceling feature, the device can distinguish between leak sounds and background noise, ensuring accurate detection even in loud environments.

4. User-Friendly Design:

The camera is structured for single-handed use, a unique feature for acoustic cameras, making it convenient for operators.

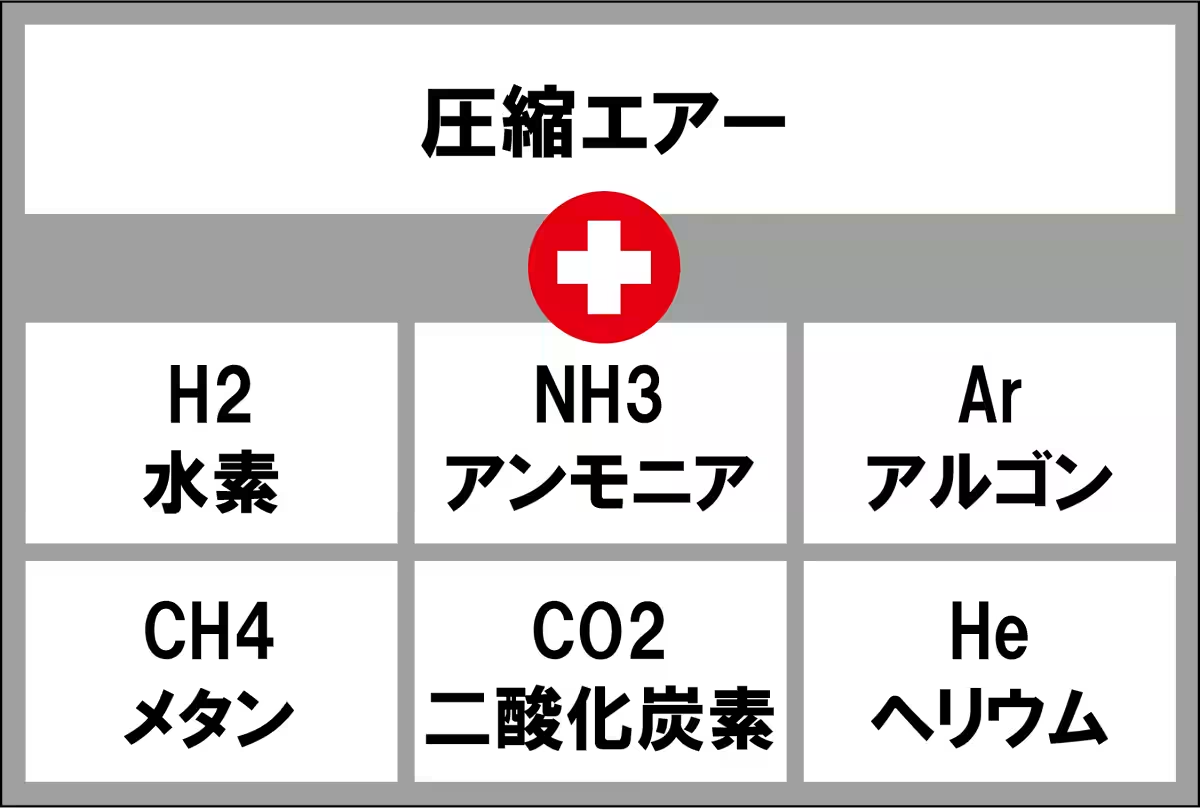

5. Multi-Gas Detection Capability:

Beyond detecting compressed air leaks, it can also identify leaks of alternative energy sources such as hydrogen, ammonia, argon, helium, methane, and carbon dioxide.

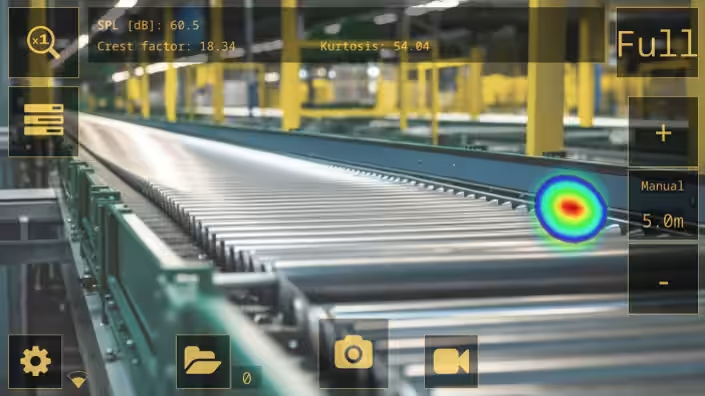

6. Bearing Fault Detection Mode:

The camera includes a mode specifically for detecting bearing anomalies, aiding in repair planning and preventing downtime. This is achieved through machine learning algorithms that assess the equipment's status and highlight potential issues.

7. Report Generation:

Using Wi-Fi, users can easily transfer captured images to the FLIR Acoustic Camera Viewer, simplifying report creation for maintenance and efficiency assessments.

Supporting Industrial Temperature Management

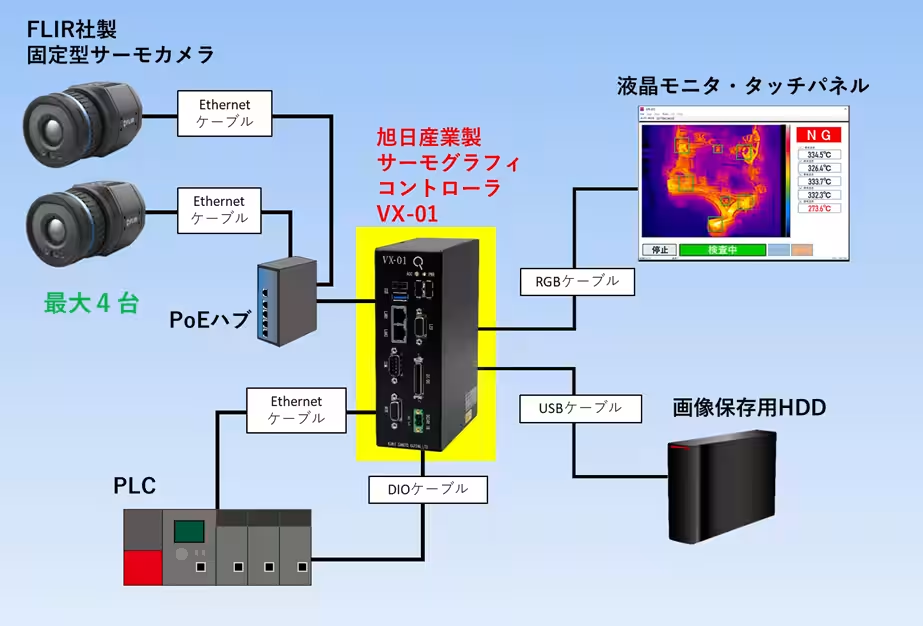

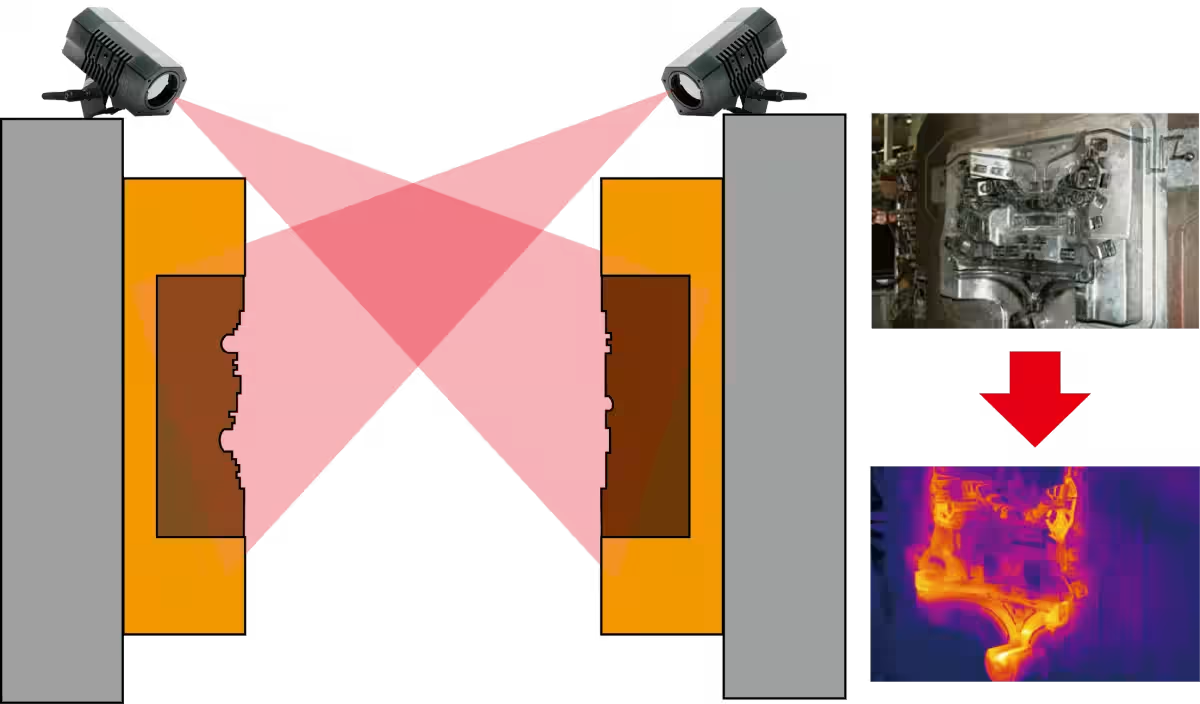

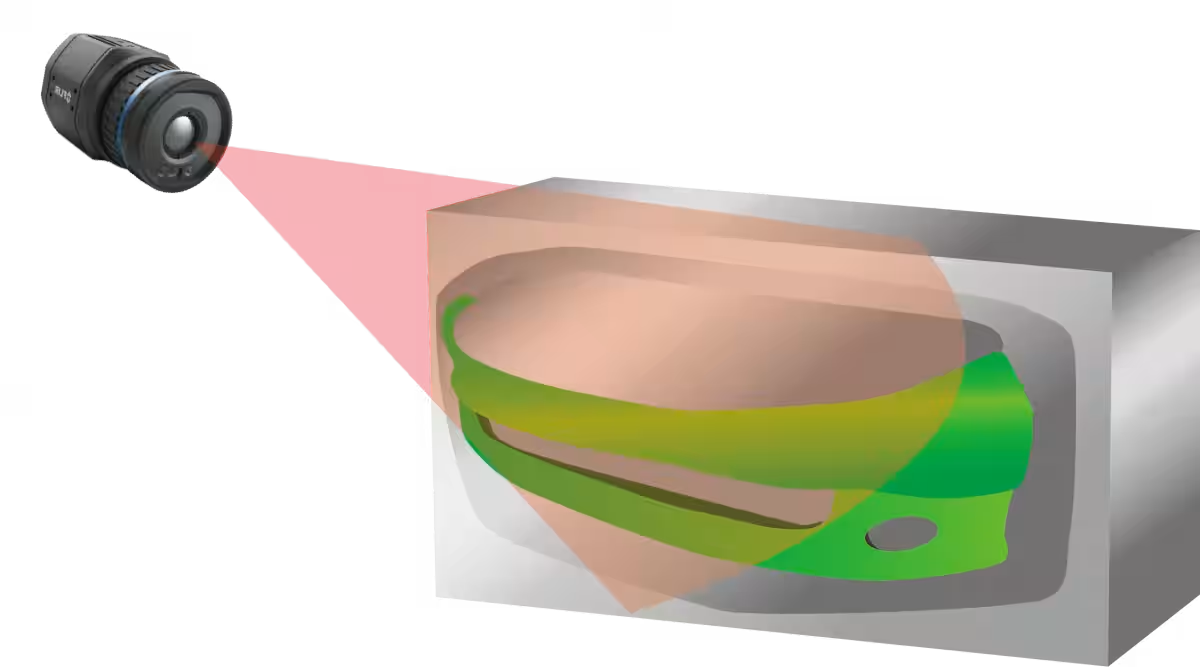

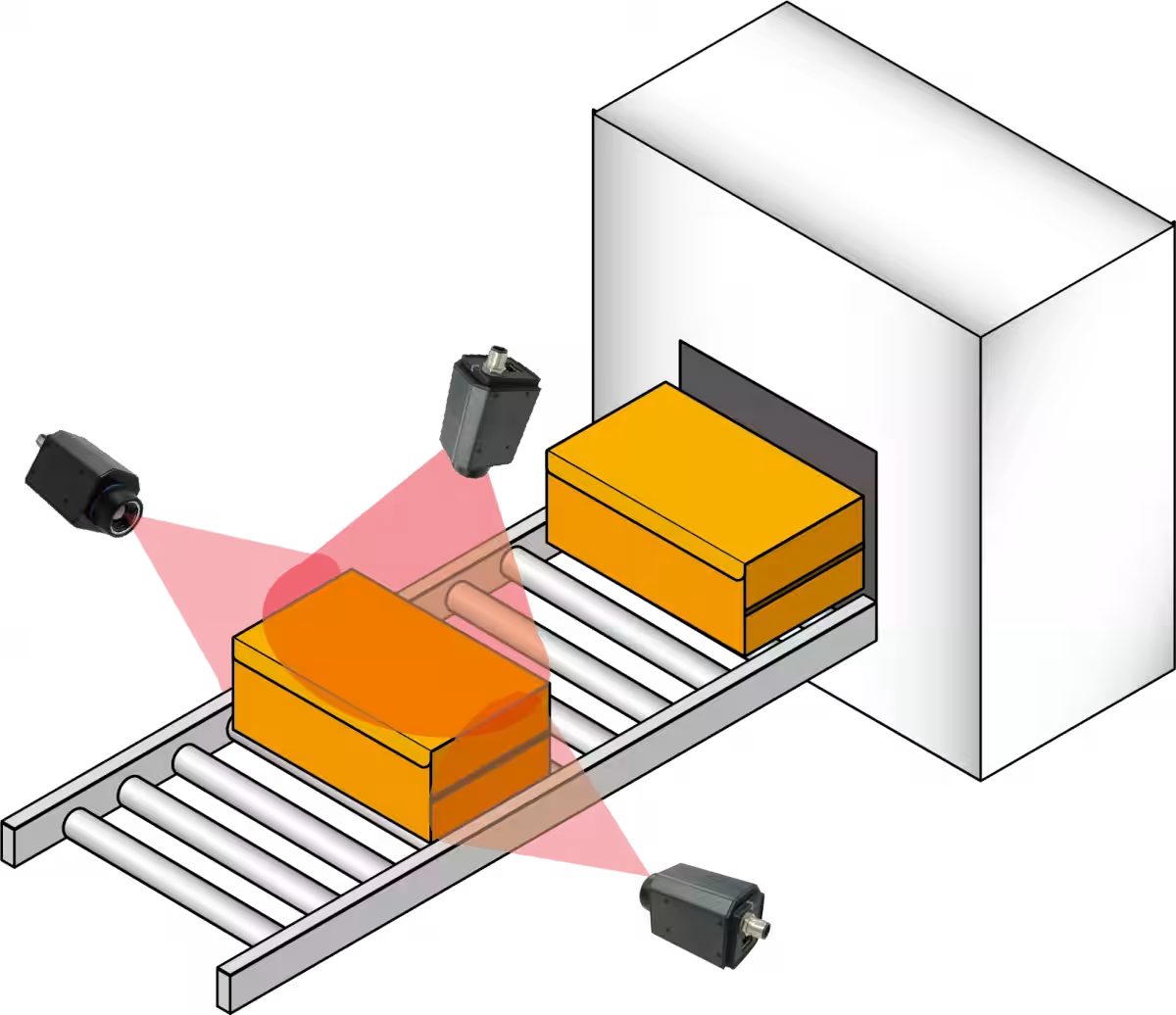

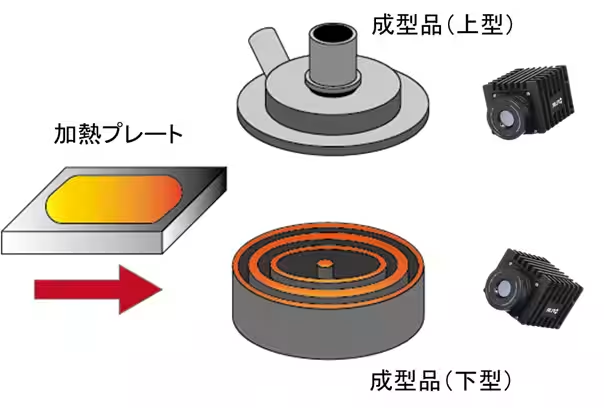

In addition to air leak detection, FLIR offers a sophisticated Thermography Inspection System to manage temperature—another critical factor in manufacturing processes. Temperature control is vital but challenging due to its invisible nature.

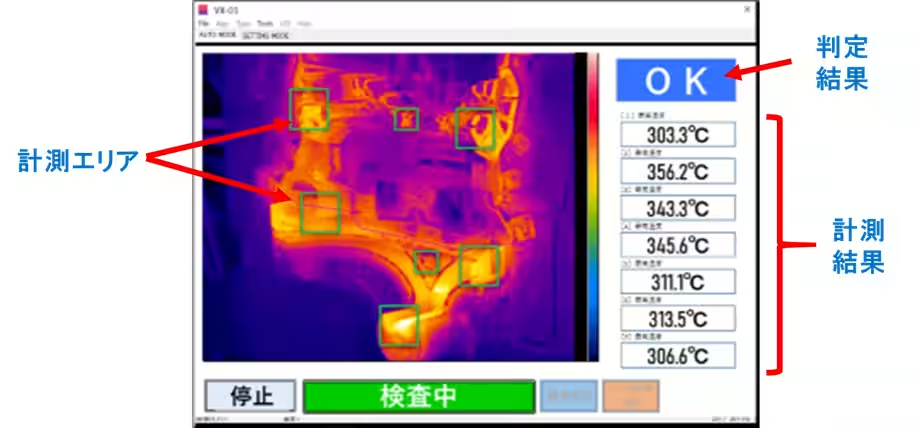

The Thermography system integrates high-performance automation-grade thermal cameras from FLIR, enabling precise inspection and quality control in various production processes. Key features include:

- - A temperature measurement range from -20°C to 2000°C

- - High resolution: Up to 640x480 pixels

- - Ethernet connectivity options for seamless data transfer

- - Custom-developed image processing controllers that enhance measurement capabilities.

Applications of Thermography Inspection System

Different applications where the thermography system can be a game-changer include monitoring die temperatures in die-casting machines, inspecting resin temperatures during injection molding, controlling temperatures for hot-melt applications in packaging, and more. By monitoring temperature changes in real-time, manufacturers can assure their product quality and maintain strict compliance with operational standards.

For further inquiries or to explore the full capabilities of the FLIR air leak detection camera and thermography inspection system, visitors can contact Asahi Industry Co., Ltd. via their website or directly at their Tokyo office.

With systems like these, FLIR continues to lead the way in advancing industrial efficiency and sustainability, vital in today's energy-conscious climate.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.