Exploring the Integration of AI in Japan's Manufacturing Sector: Challenges and Insights for 2025

Unveiling the AI Landscape in Japanese Manufacturing

In recent years, Japan's manufacturing industry has been undergoing a significant digital transformation, with AI technology emerging as a pivotal factor in enhancing operational efficiency and competitiveness. A survey conducted by Caddie Inc., a Tokyo-based startup focused on unlocking the potential of the manufacturing sector, sheds light on the current challenges and future prospects of AI utilization within this vital industry.

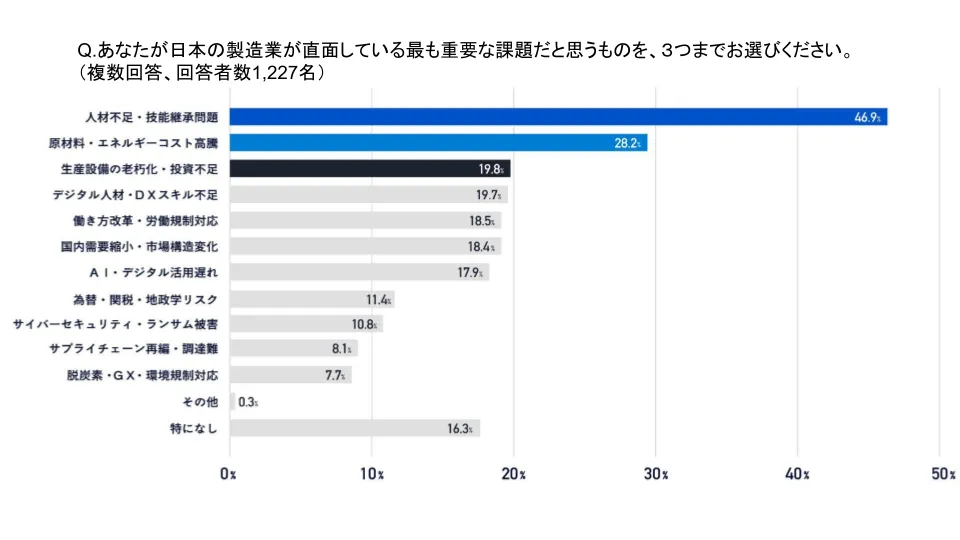

Overview of the Survey

The survey involved 1,227 manufacturing professionals and aimed to explore their perspectives on the integration of AI in their operations. The findings highlight pressing issues facing the industry, particularly with 46.9% of respondents identifying labor shortages and skill transfer as the primary challenge. Following closely were the skyrocketing costs of raw materials and energy (28.2%) and the aging production equipment coupled with inadequate investment (19.8%).

Key Challenges in the Industry

The manufacturing landscape is fraught with complexities that threaten its growth. The scarcity of skilled labor has been underscored as a dominant concern, indicating that a substantial percentage of employees feel the weight of navigating the workforce's limitations. Additionally, the high costs of materials alongside the need for modernized machinery remain critical points of tension that hinder progress.

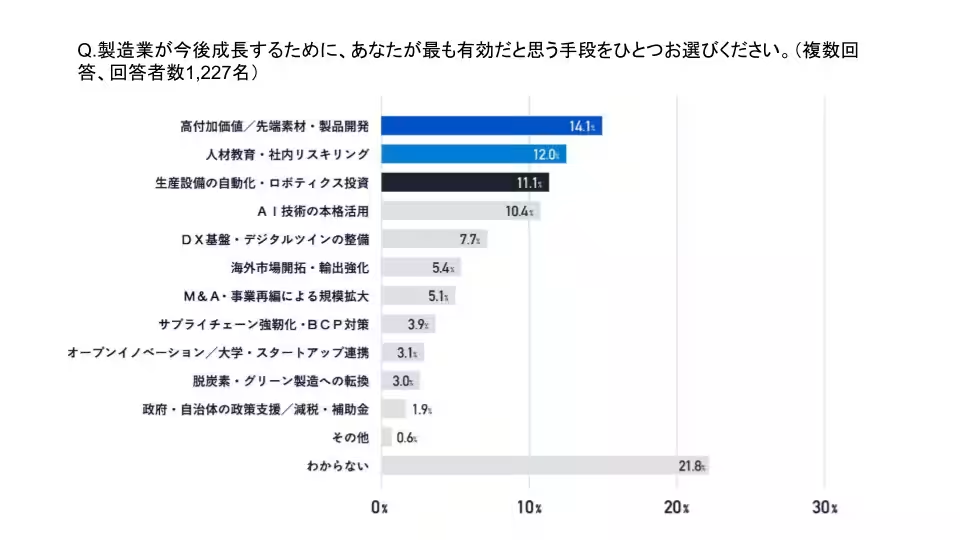

Growth Strategies for Manufacturers

To counteract these challenges, respondents have indicated viable strategies for growth, emphasizing high-value materials and advanced product development (14.1%) as a crucial avenue, with human resource education and internal reskilling (12.0%) also recognized as important. Interestingly, 11% of managerial staff highlighted the potential of fully integrating AI technologies into their operations.

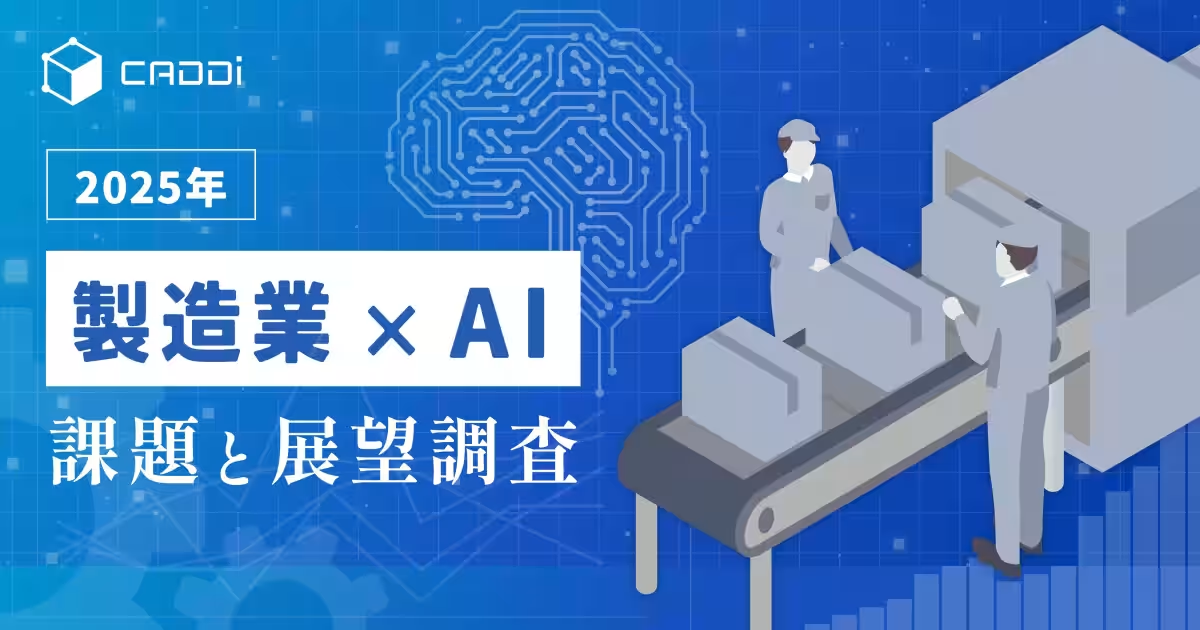

Inefficiencies in Operational Processes

The survey pinpointed inefficiencies across various business processes, particularly in inventory, warehouse, and shipment management, along with production setup and financial reporting. Each of these areas reported a significant proportion of respondents identifying room for improvement, suggesting that multi-faceted operational upgrades are vital for advancement.

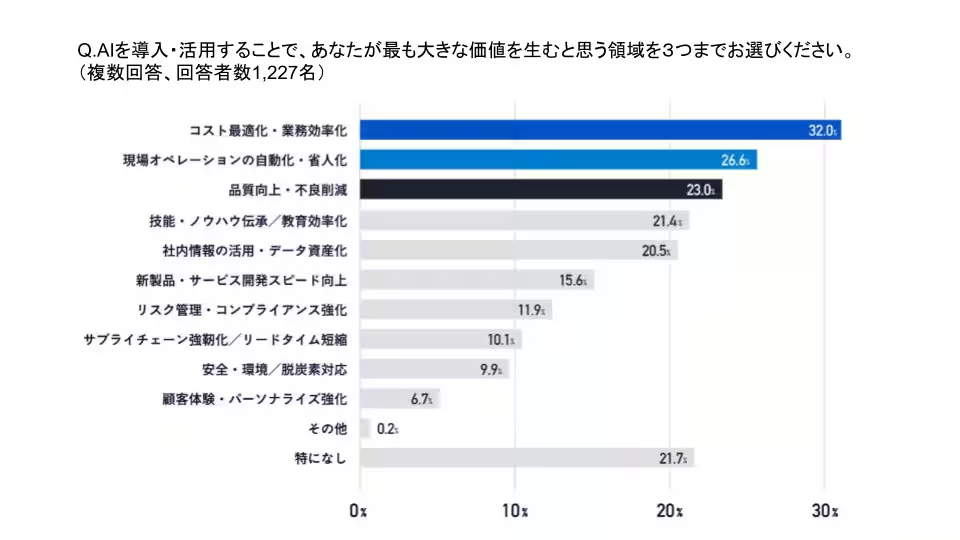

The Value of AI Implementation

When asked where AI could provide the most substantial benefits, approximately 30% of participants cited cost optimization and operational efficiency as key areas of impact. Furthermore, the automation of on-site operations (26.6%) and enhancing product quality while reducing defects (23.0%) were also deemed significant contributions.

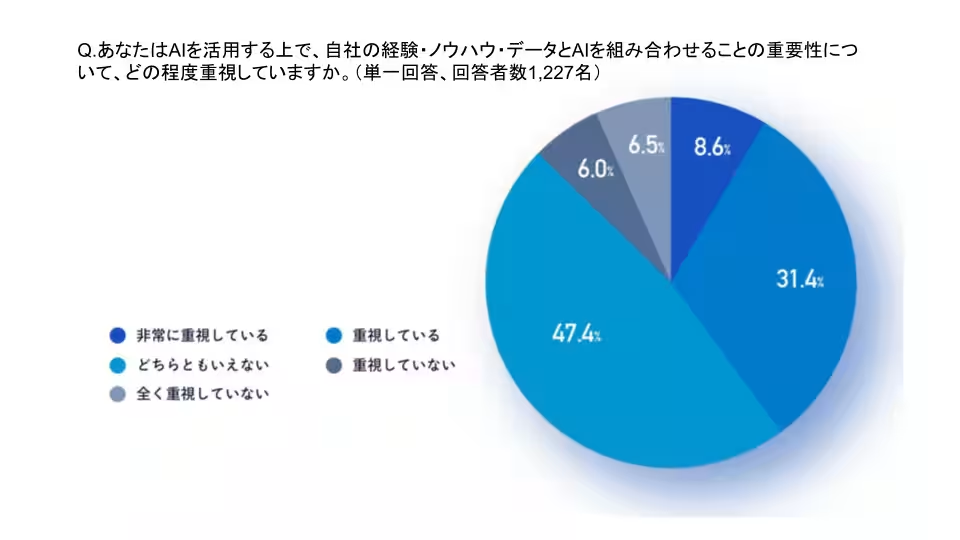

The survey revealed that a notable 40% of respondents prioritize the importance of merging their own company data, know-how, and experience with AI solutions. In contrast, just 12.6% regarded this integration as unimportant, underscoring a strong recognition of the necessity to leverage internal expertise alongside technological advancements.

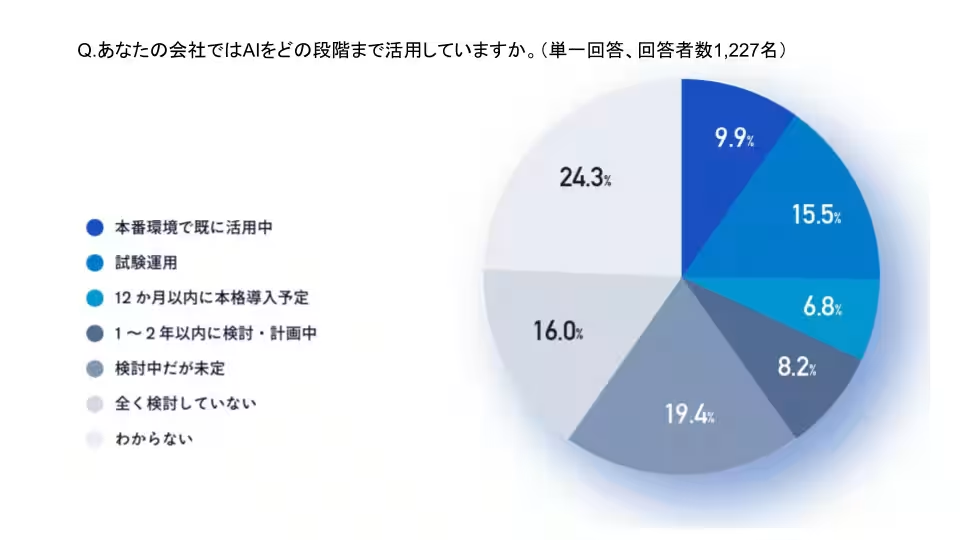

Current State of AI Adoption

Despite these revelations, the actual implementation of AI in working environments remains dismally low, with only about 10% operating AI systems actively. Alarmingly, nearly 40% of respondents reported either not considering AI at all (16.0%) or being in a state of indecision regarding its application (19.4%). This highlights a clear disparity between awareness and actual utilization within Japan's manufacturing sector.

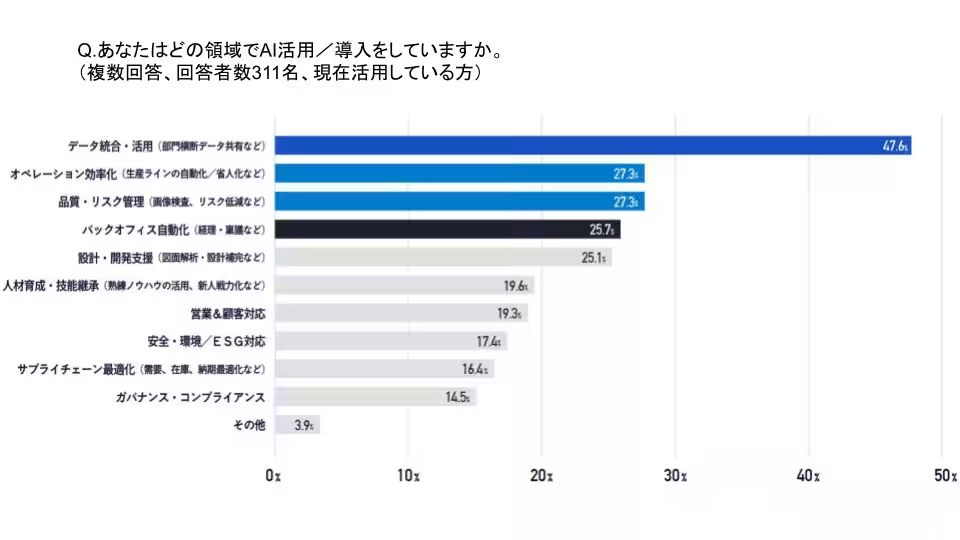

Areas of AI Deployment

Among those already utilizing AI, nearly half have opted for data integration and utilization, while others focused on quality and risk management (27.3%) and operational efficiency (27.3%) as primary domains for AI application.

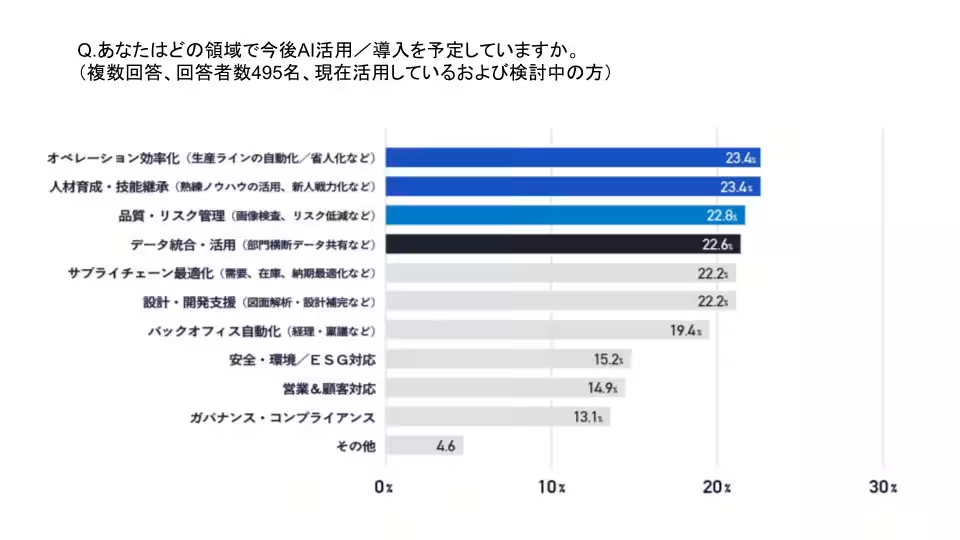

Respondents also projected intentions to utilize AI in vital areas, with human resource development and skill transfer (23.4%) tying with operational efficiency (23.4%), followed closely by quality and risk management (22.8%).

Barriers to Widespread AI Use

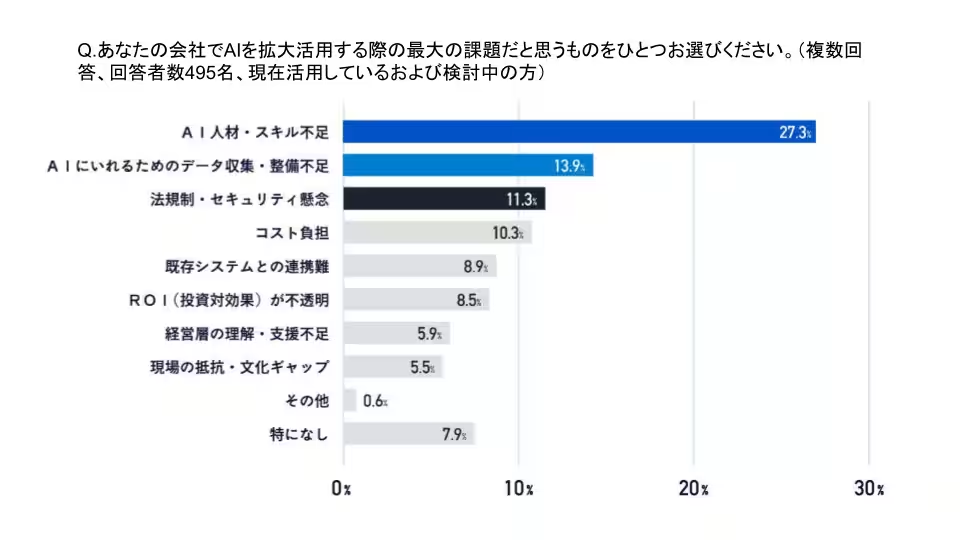

Among the various obstacles impeding broader AI adoption, a significant 27.3% pointed to a lack of AI-skilled personnel as the foremost barrier. Furthermore, 13.9% cited insufficient data collection and management as a challenge in integrating AI solutions, while about 10% expressed concerns about regulatory and security issues, indicating a pressing need for both company-driven efforts and government support in advancing AI integration.

Conclusion

The findings from Caddie's survey illuminate the critical landscape of Japan’s manufacturing sector as it navigates complex challenges, with labor shortages and rising costs posing significant threats to growth. However, there remains optimism in the form of AI technology, with potential growth strategies focusing on high-value materials, product development, and the essential internal reshaping of workforce capabilities. The importance of integrating company data with AI tools emerges as a decisive factor in leveraging this technology for substantial benefits. The report calls for targeted investment in AI-driven solutions while recognizing that overcoming created barriers will necessitate both industry initiatives and supportive governmental policies.

---

About Caddie Inc.

Caddie Inc. is dedicated to liberating the potential of manufacturing industries with its mission to capitalize on fragmented data and experiences to create new value. Offering an AI data platform tailored for manufacturing, Caddie aims to revolutionize the sector across four countries, including Japan, the USA, Vietnam, and Thailand. With a cumulative equity funding totaling ¥25.73 billion, Caddie is poised to drive a global transformation in the manufacturing arena.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.