Gab Launches Innovative Circulation Solution .Garbon to Achieve Zero Waste Society

Gab's Commitment to a Zero Waste Society with .Garbon

In a significant move towards sustainability, Gab Inc., headquartered in Shibuya, Tokyo, has unveiled .Garbon, an innovative circular solution leveraging carbonization technology. This initiative aims to transform various waste materials, often deemed non-recyclable, into selectable resources such as synthetic leather, marking a pivotal step towards achieving a zero waste society.

Background and Need for Change

The push for a sustainable society underscores the importance of waste reduction and CO₂ emissions mitigation as globally mandated goals. Japan faces pressing challenges, with approximately 3.16 million tons of incineration ash ending up in landfills each year. Experts predict we might reach landfill capacity within 22 years unless decisive actions are undertaken. Moreover, 1.5 million tons of plastic waste is exported annually, contributing to environmental pollution in host countries.

Currently, the country's reuse rate stands at only 3%, and recycling efforts hover around 22%, illustrating the inadequacy of traditional “Reduce, Reuse, Recycle” (3R) strategies. As numerous companies commit to zero waste and carbon neutrality by 2030, the pressing need for a more effective “fourth solution” has become apparent.

Gab's .Garbon arises as a response to these critical challenges. By utilizing carbonization technology, the initiative addresses the inability to recycle certain waste types, generating new resources and enabling businesses to meet both waste reduction and CO₂ emission reduction goals.

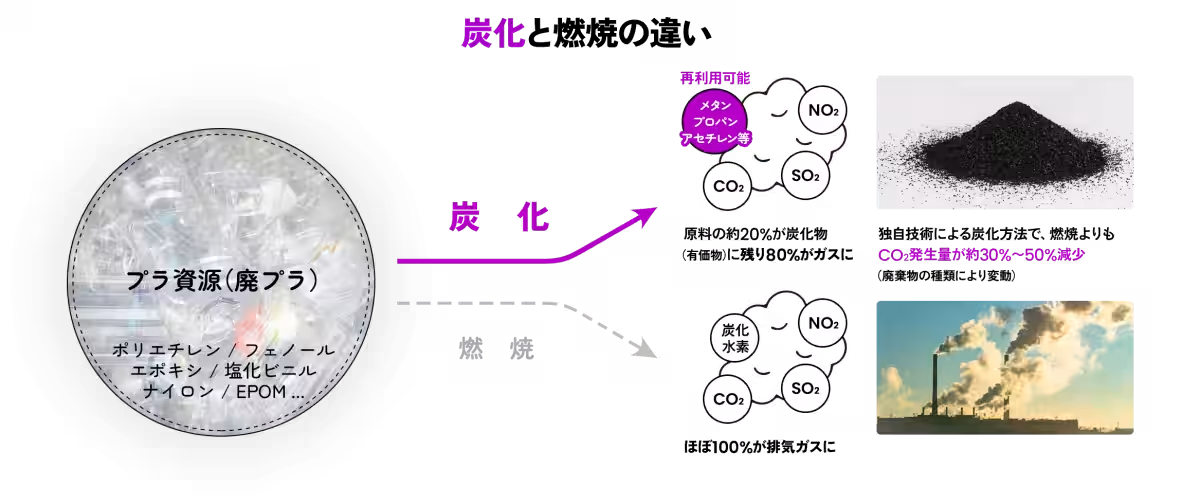

How .Garbon Works

.Garbon operates by converting previously difficult-to-recycle organic waste, such as plastics and food scraps, into a uniform carbon powder through an anaerobic thermal decomposition process. This innovative technology ensures a reduction in CO₂ emissions by approximately 30-50% compared to traditional incineration methods. Roughly 80% of treated waste transforms into thermal energy, with the remaining 20% yielding solid carbon resources for various applications.

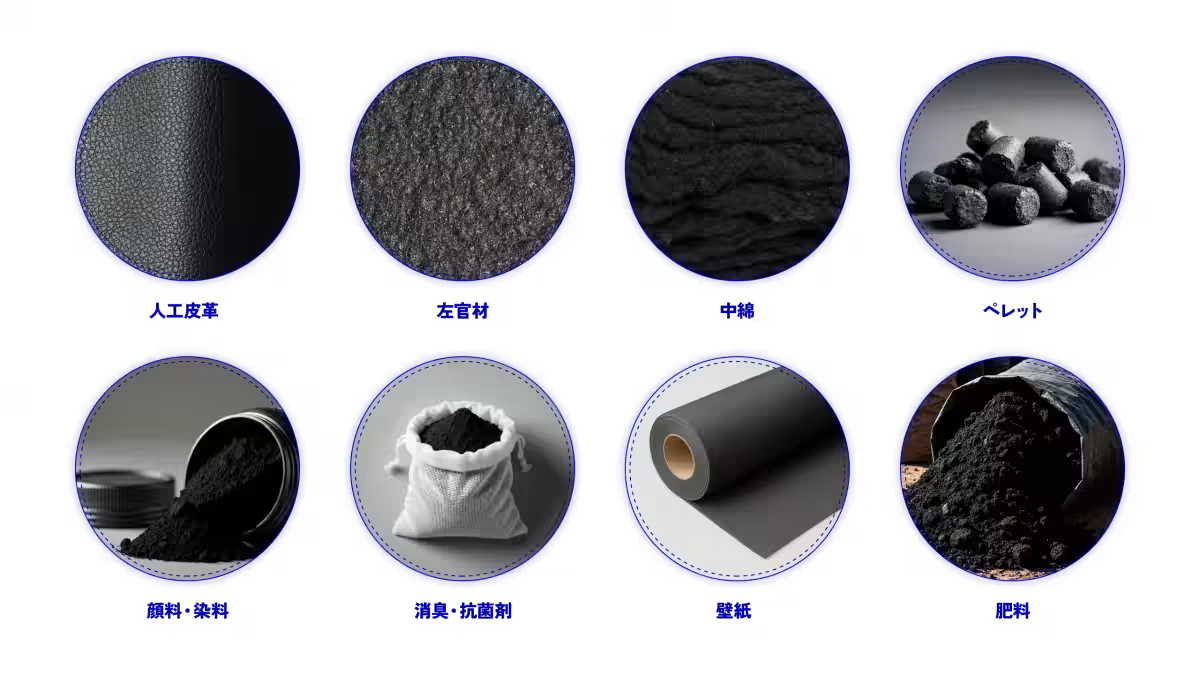

The versatility of the carbon powder not only serves as a black pigment but also boasts beneficial properties like deodorization, antibacterial effects, and far-infrared heat retention. These features allow the material to be repurposed into high-value products, including synthetic leather, building materials, and fibers.

Potential Applications of .Garbon

One of the standout innovations stemming from .Garbon is the .Garbon Synthetic Leather, which can be integrated into various fashion items, interior designs, and construction materials. This new material incorporates carbon powder derived from waste into resin, enhancing functionality through deodorizing and antibacterial properties.

Collaborating with domestic synthetic leather manufacturers has fortified the quality of .Garbon products, achieving high standards in durability and aesthetic appeal. Notably, the synthetic leather is lightweight (less than half the weight of genuine leather) and water-resistant, ensuring ease of maintenance. With sustainability at the forefront, .Garbon's synthetic leather also offers a significant reduction in CO₂ emissions when compared to traditional leather, emphasizing its potential for a circular economy.

Partnerships and Future Development

Gab collaborates with Oki Koge Co., a pioneer in carbonization technology, to perfect the processing and material transformation. This partnership enables a seamless development cycle, tackling the complexities of mixed waste that has previously been considered difficult to process.

The partnership extends to Toyota Motor Corporation, where .Garbon has begun pilot testing within the Toyota Upcycle Project. This collaborative effort is focused on converting manufacturing waste into new sustainable materials, further accelerating the shift towards eco-friendly automotive industry practices.

Expanding Horizons

Following its initial success, Gab intends to broaden .Garbon's application beyond the automotive sector, targeting industries such as fashion, construction, and consumer goods for comprehensive adoption of the “buying waste → carbonization → re-materialization → re-distribution” model.

Recognizing that waste characteristics vary across sectors, Gab also envisions establishing a Zero Waste Consortium to provide tailored solutions in collaboration with other firms tackling circular economy challenges.

As part of this initiative, Gab is currently inviting ten companies to participate in an introductory program featuring an accompanying carbonization validation, aimed at lowering the barriers to effective resource circulation adoption.

Conclusion

Gab continues to lead the charge towards a sustainable future, firmly believing that .Garbon represents not just a technological advancement but a societal shift towards achieving a zero waste paradigm. By fostering a new ecosystem of sustainability, Gab is not only addressing waste management but also igniting a movement towards responsible consumption and production.

For detailed inquiries and collaborations, visit Gab's official website at Gab Inc..

Topics Environment)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.