Robosensor Technologies Unveils RH600 Series for Digitalizing Touch and Minimizing Human Error

Introduction

In a remarkable advancement for the manufacturing industry, Robosensor Technologies, Inc., headquartered in Hamamatsu, Japan, has unveiled its latest product, the RH600 Series. This innovative integrated system combines tactile sensing and AI technologies to revolutionize quality control by effectively minimizing human errors on production lines. Sample distributions are set to commence in July 2025, marking a significant milestone for manufacturers around the globe.

Features of RH600 Series

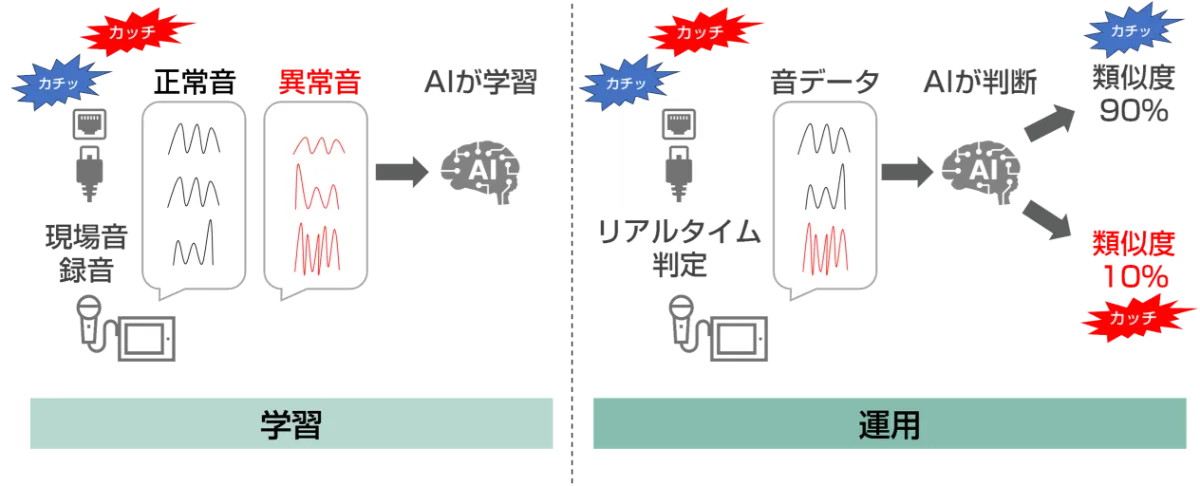

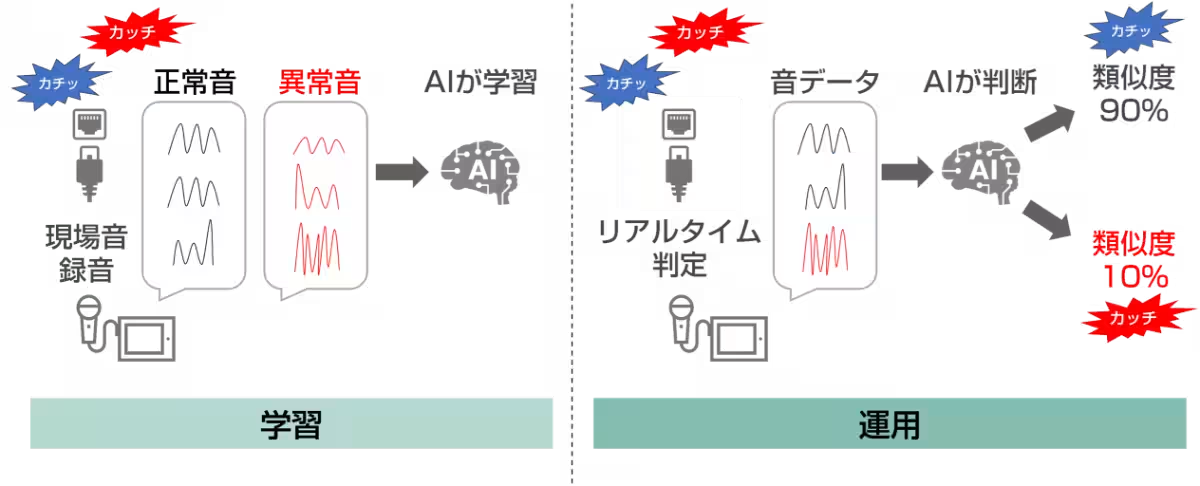

At the heart of the RH600 Series is a unique technology that captures minute vibrations and pressure changes through ultra-sensitive sensors. These state-of-the-art tactile sensors translate the subtle feedback from human fingertip touch into quantifiable data in real time, enabling comprehensive visualization and standardization of manual processes. The system’s wireless design further enhances its usability, allowing continuous operation for over 10 hours without hindering worker movement.

The RH600 Series replaces the traditional reliance on visual inspections and experiential judgments with standardized and precise AI evaluations that offer instant feedback. Its deployment has gained traction particularly in sectors that demand exceptionally high quality control standards such as automotive parts, precision machinery, and medical device manufacturing.

Industry Applications

The versatility of the RH600 Series allows it to serve a myriad of functions across various manufacturing processes. For instance,

- - Assembly Monitoring: It can monitor the manual assembly processes of intricate parts like wire harnesses, quickly identifying and mitigating potential human errors.

- - Quality Management: The system provides valuable data that can be utilized to standardize workflows within assembly lines, turning skilled labor activities into quantifiable standards for quality assurance.

- - Precision Monitoring: For industries producing complex medical devices and precision components, the RH600 ensures quality is consistently high, preemptively addressing defects to maintain product integrity.

- - Predictive Maintenance: By monitoring subtle changes in equipment vibrations, the system can forecast maintenance needs, thereby preventing unexpected machinery failures and enhancing operational efficiency.

Comprehensive Support and Implementation

Robosensor Technologies goes beyond merely providing the product; it also ensures comprehensive support for users. The company offers product demonstrations, technical training, and ongoing integration assistance through its network of distribution partners. This support is designed to help manufacturers seamlessly integrate the RH600 Series into their operations, ensuring a smooth transition to enhanced digital touch capabilities.

Conclusion

The globalization of manufacturing continues to evolve, and with it, the demand for innovative technological solutions like the RH600 Series is increasing. Robosensor Technologies is stepping up to meet this demand, offering a product that not only digitizes touch but also enhances the overall efficiency and reliability of manufacturing processes. As industries embrace this cutting-edge technology, it becomes evident that the RH600 Series is set to redefine quality control standards on a global scale.

For more information, visit Robosensor Technologies.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.