Revolutionary Iron Catalyst Converts Polyester Waste to High-Purity Chemical Raw Materials

Transforming Waste: The Future of Polyester Recycling

The world is grappling with an urgent plastic waste crisis, and innovative scientific solutions are in high demand to tackle this issue efficiently. In a significant development, a research group led by Professor Kotohiro Nomura from Tokyo Metropolitan University has created a high-performance iron catalyst capable of converting polyester, including materials from plastic bottles and textile waste, into chemical raw materials with near-total efficiency (99.7 to 99.9%). This advancement not only simplifies the recycling process but also promises to provide a strong foundation for a resource-circulating society.

The Polyester Waste Challenge

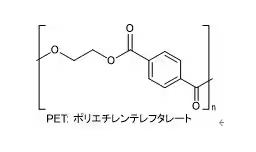

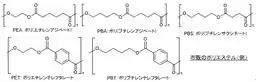

Plastic waste primarily consists of materials like polyethylene terephthalate (PET), commonly found in beverage bottles and clothing. Although recycling initiatives are in place, the reality is that most plastic waste is merely repurposed as fuel rather than effectively recycled into new raw materials. The challenge lies particularly in the recycling of PET, where existing methods often suffer from quality degradation issues, forcing many to use high temperatures and excessive inorganic bases or acids, contributing to environmental pollution. Thus, developing a more straightforward, cost-effective method that maintains low environmental impact has been crucial.

A Breakthrough in Chemical Recycling

The team focused on developing a catalyst that could transform polyester into useful monomers without the need for excessive inorganic bases. Their breakthrough lies in a simple procedure where polyester is mixed with alcohol and heated. Surprisingly, under milder conditions than any previous processes, the new iron catalyst displayed remarkable efficiency. The performance of this catalyst allows for the near-total conversion of the original polyester constituents into pure terephthalate esters and other valuable products without any degradation.

The practical implications of this research are profound. The catalyst performs excellently, even when applied to real-world samples, revealing an impressive collection rate of near 100% from PET waste or textile discards. This not only marks a revolutionary step in chemical recycling but also supports the broader vision of establishing a sustainable resource-circulating society.

Methodology and Results

The newly developed iron catalyst was tested under conditions that mimic actual recycling scenarios. Remarkably, it achieved high conversion efficiency (99.7-99.9%) with minimal degradation of the material quality. Following just simple purification processes, high-purity chemical raw materials can be obtained, and various alcohols can be employed in the reaction, enhancing versatility. The implications are significant: the ability to isolate polyester from mixed fabrics means that this technology could revolutionize recycling practices across industries where synthetic fibers are commonly used.

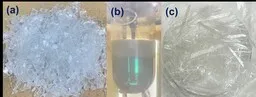

Visual Evidence of Success

To illustrate, the research included experiments that showed:

1. PET Bottle Recycling: The recovered pet bottles were ground into chips and subsequently reacted under controlled conditions to yield nearly pure DMT (Dimethyl Terephthalate), a critical raw material.

2. Textile Waste: Polyester and cotton waste blended with alcohol were heated without acidic or basic additives, achieving quantitative separation of polyester, showcasing the catalyst’s efficiency.

Throughout experimentation, the catalyst maintained its robustness, confirming that it would perform effectively within industrial recycling facilities, further bridging the gap between laboratory-scale research and practical application.

Future Prospects

The successful development of this iron catalyst heralds a potential shift in how we approach plastic waste management. Researchers anticipate not just improvements in chemical recycling but opportunities to synthesize high-value products using these raw materials. By transforming used polyester back into usable inputs, this technology aligns with the global push for sustainability and environmental responsibility.

With expected support from entities like the Japan Science and Technology Agency’s CREST program, further advancements in this area are anticipated, paving the way for a comprehensive understanding of bio-based polymers and catalytic processes capable of addressing the plastic crisis head-on.

Conclusion

This monumental research, culminating in findings published in the ACS Sustainable Resource Management journal, signifies a turning point in how polyester waste can be effectively transformed. The work carried out under Professor Nomura’s leadership is commendable, setting a new benchmark for future developments in recycling technology and environmental sustainability.

For more detailed insights, visit the JST Press Release.

Keywords Explained

- - PET (Polyethylene Terephthalate): A common plastic used in beverage bottles and textiles.

- - Polyester: Polymers formed by the chemical reaction of alcohol and acid, which are often challenging to recycle.

- - Chemical Recycling: A process that converts waste materials into reusable chemical substances.

This research not only showcases scientific ingenuity but brings hope for a future where resource utilization aligns with ecological sustainability.

Topics Environment)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.