Kyoto University and Sunsho Pharmaceuticals Unveil Innovative 3D Printed Plant-Based Capsule Technology

Groundbreaking Research Collaboration

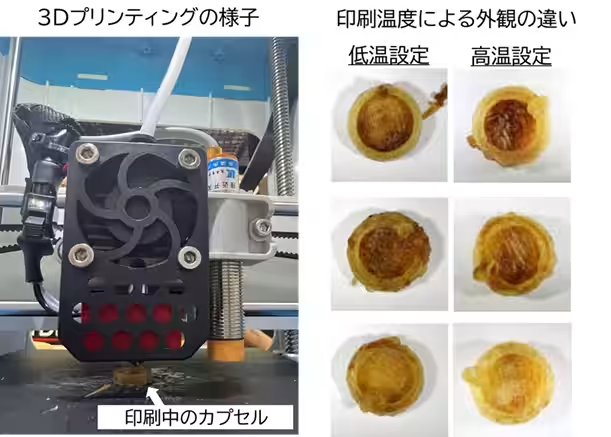

Kyoto University and Sunsho Pharmaceuticals have collaborated on an innovative project aiming to produce plant-based soft capsules using cutting-edge 3D printing technology. This significant development was unveiled during the 2025 Sapporo Conference of the Japan Society for Bioscience, Biotechnology, and Agrochemistry, showcasing the potential of sustainable materials in the pharmaceutical and health food industries.

The Research's Aim and Background

In recent years, there has been an increasing demand for sustainable technologies and environmentally friendly materials, particularly as society seeks to reduce its reliance on animal-derived components. Traditional gelatin capsules, while flexible and easy to manipulate, pose environmental challenges due to their animal sources and the manufacturing processes involved. To address these challenges, Assistant Professor Takashi Kobayashi from the Graduate School of Agriculture at Kyoto University has joined forces with Sunsho Pharmaceuticals since 2023. Their collaborative efforts have yielded a breakthrough: a capsule manufacturing technology derived from soy protein that eliminates animal ingredients, coupled with a flexible 3D printing process.

Summary of Research Findings

The presentation titled "Effects of Water Activity on the Formation of Soy Protein Films" was delivered by Miho Kurata from Kyoto University's Faculty of Agriculture and included co-authors from both Sunsho Pharmaceuticals and Kyoto University.

Key Highlights:

- - Development of soy protein-based capsules without animal ingredients, catering to vegan preferences.

- - An eco-friendly manufacturing process that avoids the use of organic solvents, significantly reducing environmental impact.

- - Utilization of 3D printing technology to allow customizable designs in terms of shape and size compared to traditional capsule making methods.

- - Applications are anticipated not only in health foods and pharmaceuticals but also in biodegradable packaging materials.

In June 2024, both entities filed a patent for the foundational concepts and materials utilized in this additive manufacturing technique.

Feedback From the Conference

The research generated considerable interest among various academic and industrial stakeholders who expressed a keen desire to further explore the technology's application. Notable comments included:

- - A university representative remarked, "While there may be challenges such as controlling pH and stabilizing filament supply, further research toward practical applications is eagerly awaited."

- - A food manufacturer stated, "I am interested to know the advantages of using soy protein compared to existing capsule manufacturing technologies."

- - A sustainability-focused company inquired, "Can this technology be adapted for materials other than soy protein?"

Future Prospects

Moving forward, Sunsho Pharmaceuticals and Kyoto University plan to combine academic insights with industrial technologies to implement these low-impact soft capsule technologies into mainstream use. They will actively seek partnerships with companies and research institutions interested in collaborative development and practical testing in areas including:

- - Joint development with food and pharmaceutical manufacturers focusing on formulation and encapsulation technologies.

- - Exploring the potential of sustainable packaging applications in conjunction with sustainability-oriented firms.

- - Supporting the development of manufacturing lines utilizing 3D printing technologies.

Comments from Project Leaders

Yoshiharu Matahei, Executive Officer and Head of Research and Development at Sunsho Pharmaceuticals, stated, "Using our established capsule manufacturing technology as a foundation, we are committed to developing sustainable new technologies. Through the implementation of this technology, we aim to promote environmentally-friendly products in the health food and pharmaceutical sectors. We look forward to fostering co-creation and advancing technology development with various enterprises and research organizations."

Assistant Professor Takashi Kobayashi of Kyoto University echoed this sentiment, emphasizing, "This research opens new possibilities for the application of plant-based proteins, and the insights provided within the fields of food science and biomaterials have substantial academic and industrial significance. I am thrilled that we can propose a novel manufacturing process through the application of 3D printing technology and look forward to deepening cooperation with businesses to drive practical technology development."

Contact Information

For those interested in obtaining this presentation material or for businesses and research institutions fascinated by the applications of this technology, please reach out to:

Sunsho Pharmaceuticals Co., Ltd.

Public Relations & Outreach – Kenichi Fujisaku

Email: [email protected]

Through ongoing innovation in formulation technology beyond just OEM for health foods and supplements, Sunsho Pharmaceuticals remains dedicated to contributing to the physical and mental well-being of people worldwide.

About Sunsho Pharmaceuticals Co., Ltd.

- - Location: 1468 Atsuhara, Fuji City, Shizuoka Prefecture, Japan

- - CEO: Akira Imamura

- - Established: November 1993

- - Capital: 1,233,890,000 JPY

- - Revenue: 25 billion JPY (Fiscal Year ending March 2024)

- - Employees: 700 (as of January 2025)

- - Business Scope: Planning, development, and contract manufacturing of health foods, pharmaceuticals, general food products, and miscellaneous goods.

- - Website: Sunsho Pharmaceuticals

Topics Health)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.