Streamlining Hazardous Substance Management with SmartMat Cloud: A Case Study

Automating Hazardous Substance Management with SmartMat Cloud

In a significant advancement towards modernizing inventory management, Esumat Inc., based in Shinagawa, Tokyo, has published a compelling case study showcasing the effectiveness of its IoT-based inventory management solution, SmartMat Cloud. Designed to streamline the management of hazardous substances, this innovative system has significantly slashed the time required for inventory checks at the Sumitomo Bakelite Shizuoka plant, transforming a cumbersome process into one that is both efficient and manageable.

Background of the Implementation

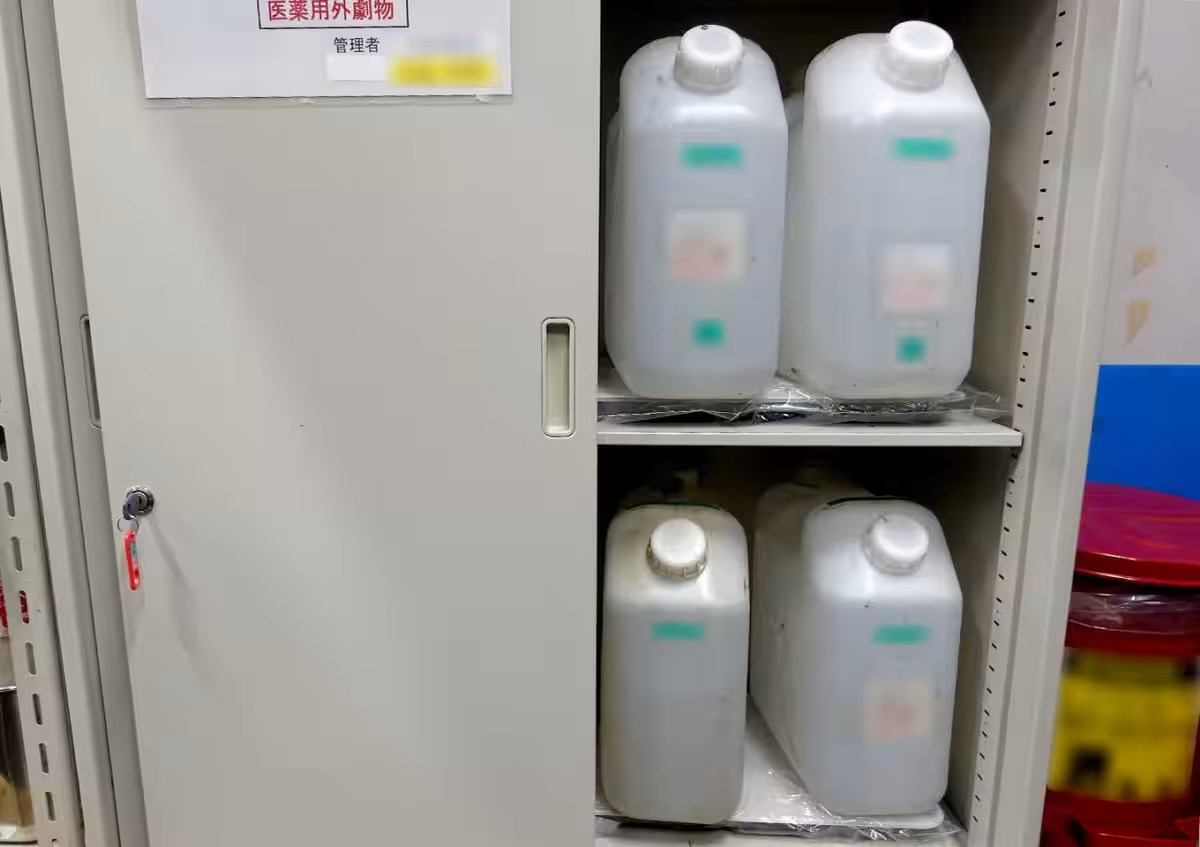

The Shizuoka plant of Sumitomo Bakelite serves as a pivotal hub for high-performance plastic manufacturing. This site not only engages in material development but also produces finished products. However, the plant has been burdened with the regulatory demands of hazardous substance management. Tasks like inventory checks, weight measurements, and paper record approvals traditionally consumed an entire day or more, thereby posing a threat to both safety and operational efficiency. Particularly, weighing containers exceeding 10 kilograms was a daunting manual task, increasing risks and physical strain on employees. Therefore, optimizing this process was deemed essential.

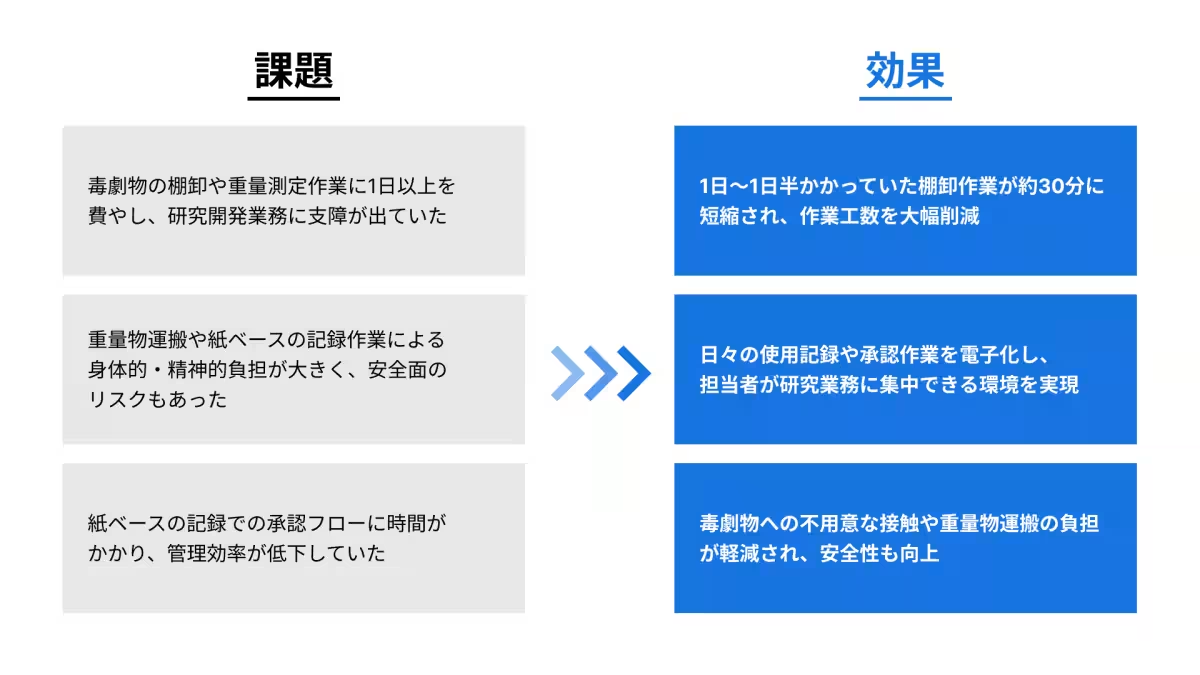

Challenges and Benefits of Implementation

The primary challenge lay in overcoming the legacy systems that had long been entrenched in the plant's operations. Introducing SmartMat Cloud required not just technical changes but also fostering a shared understanding among the staff. Esumat's solution promises not only robust management but also promotes employee safety and enhances operational efficiency. The implementation resulted in reducing the inventory management time from a daunting one to one-and-a-half days to a mere 30 minutes.

In essence, SmartMat Cloud automates inventory control, thus alleviating the physical and mental strain on employees. This transformation addresses industry concerns regarding safety and productivity, representing a pivotal shift in workplace practices.

Overview of SmartMat Cloud

SmartMat Cloud is an innovative DX (Digital Transformation) solution that visualizes actual inventory through IoT technology, making inventory management straightforward and ensuring process improvements. By automating cumbersome tasks such as inventory counts and facilitating real-time inventory visibility, the application elevates the management of stock levels while enhancing operational workflows. Since its inception in the winter of 2018, SmartMat Cloud has penetrated various sectors — from manufacturing and service industries to healthcare facilities — achieving adoption across over 1,200 companies.

Company Profile: Esumat Inc.

Formerly known as Smart Shopping, Esumat Inc. aims to create a super-smart flow of daily inventory. The company has developed user-friendly IoT weight measurement tools to automate inventory management and provide B2B solutions. The SmartMat Cloud service not only guarantees effective stock management but also automates inventory checks and orders. Established in November 2014, Esumat operates from Shinagawa, Tokyo, under the leadership of President Takayuki Shiga and Executive Officer Hidetoshi Hayashi.

Closing Thoughts

The case study on the results of implementing SmartMat Cloud not only showcases the positive impact on operational efficiency but also sets a benchmark for how innovation can redefine conventional practices within industries dealing with hazardous substances. By significantly reducing the burdens associated with inventory management, there is a pathway towards improved safety, enhanced efficiency, and a commitment to maintaining high standards in workplace practices.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.