Wood-Covered Steel Component "Kigurumi HB" Expands with First License Agreement with Three Companies

Introduction

Sumitomo Forestry Co., Ltd., led by President Toshirou Mitsukoshi, is embarking on a significant expansion of its innovative wood-covered steel member, the "Kigurumi HB" column. This unique construction material has been recognized for its fire-resistant properties, and now, through newly established licensing agreements with three laminated timber manufacturers, it is set to reach a wider market.

Licensing Agreements

The licensing agreements which commenced this November involve partnerships with three reputable companies: Saito Wood Industry Co., Ltd., Shida Lumber Co., Ltd., and Fujiju Industry Co., Ltd. This marks the first time Sumitomo Forestry is licensing its developed materials to third parties for production and sales. The objective of these agreements is to promote the use of wood in mid to large-scale construction, enhancing sustainability and reducing environmental impact.

Innovative Features of Kigurumi HB

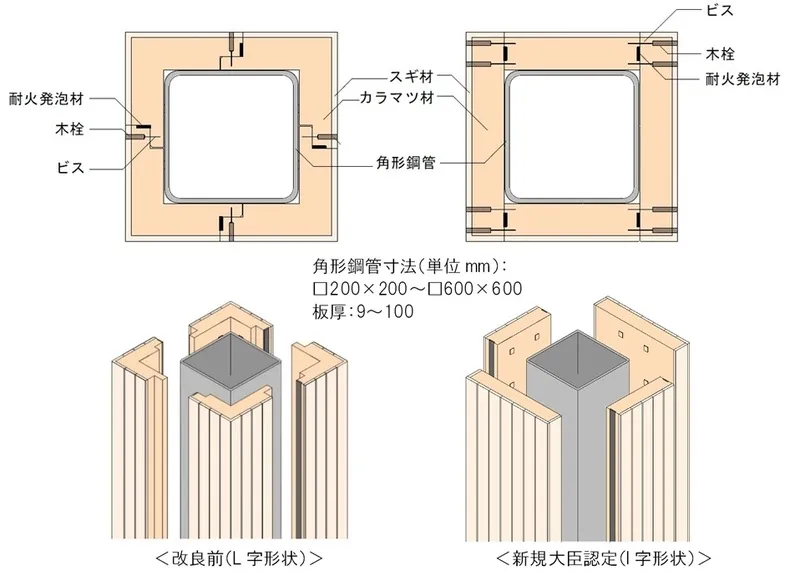

The Kigurumi HB column, designed in a shape reminiscent of I-beams, has recently obtained a Ministerial Certification for one hour of fire resistance as of September 1. This innovative product is an evolution of the previously developed wood-covered steel member, which features a new cover shape that enhances the product's functionality and efficiency.

Environmental Benefits

The significant advantage of the Kigurumi HB lies in its two-layer construction, which utilizes the unique burning properties of Japanese larch and cedar. This unique design increases the charring effectiveness of the larch while maintaining the required fire resistance solely using wood without additional inorganic materials such as gypsum boards, thus substantially reducing greenhouse gas emissions.

Cost-Effectiveness

By simplifying the cover parts from an L-shape to an I-shape, production costs have been reduced by approximately 20%. This design not only streamlines manufacturing but also improves transport efficiency, making it easier to handle on construction sites.

On-Site Assembly

The newly designed Kigurumi HB components arrive at construction sites in pre-manufactured sections allowing for easier assembly with screws and wooden dowels. This efficient onsite assembly process minimizes the risks of damage during welding or exposure to the elements. The improvements made to the product geometry enhance both transportation and installation, making it a practical solution for modern construction challenges.

Future Plans

The push towards integrating wooden elements into steel or reinforced concrete structures is steadily increasing, and the demand for fire-resistant wooden coatings is on the rise. By collaborating with laminated timber manufacturers, Sumitomo Forestry aims to expand the utilization of the Kigurumi HB in mid to large-scale buildings. They are committed to developing fire-resistant members that are structurally versatile and environmentally friendly.

Sumitomo Forestry is dedicated to a long-term vision termed "Mission TREEING 2030," aimed at enhancing CO2 absorption through forest management, promoting wooden construction, and contributing to carbon fixation. This commitment not only supports the company’s own goals but also contributes to broader societal efforts towards decarbonization.

In conclusion, through strategic partnerships and innovative materials, Sumitomo Forestry is setting a precedent in the construction industry, promoting sustainability and providing efficient solutions for future building endeavors.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.