Innovative Weather-Resistant Float Covers Developed for Oyster Farming to Combat Marine Debris

Innovative Solution to Marine Debris

In recent years, the issue of marine debris has become increasingly pressing, particularly in regions with significant oyster production, such as Hiroshima Prefecture. Maeda Kosen Co., Ltd., a leading manufacturer of civil engineering materials and non-woven fabrics, has developed a weather-resistant float cover specifically for oyster farming rafts to address this environmental challenge.

Background of the Development

Hiroshima Prefecture is known for its oyster production, boasting over 300,000 Styrofoam floats used in aquaculture. Unfortunately, deterioration and outflow of these floats pose serious environmental concerns regarding marine debris. The company recognized that various factors contribute to the degradation and loss of these floats and aimed to innovate with a new solution.

The weather-resistant float cover is designed using a reinforced fabric that enhances durability compared to conventional options. This development is a step forward in preventing the float degradation that has plagued oyster farming in the area.

Installation and Monitoring

Maeda Kosen is collaborating with Setouchi Oceans X and the Hiroshima Prefectural Fisheries Cooperative Association to install 1,000 floats equipped with the weather-resistant covers in offshore locations, equivalent to 30 oyster rafts. This initiative kicks off a large-scale monitoring project for the new cover, highlighting its potential impact on reducing marine debris in this vital ecosystem. Setouchi Oceans X is part of a comprehensive marine debris countermeasure project initiated in December 2020, involving the four prefectures facing the Seto Inland Sea.

Technical Features of the Weather-Resistant Float Cover

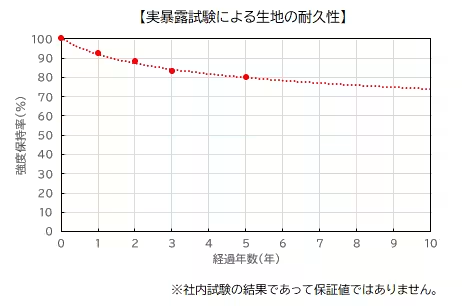

Many current float covers are designed to prevent deterioration and improve handling. However, these conventional products often fail within 2 to 3 years as the fabric and stitching break down, exposing the Styrofoam float underneath. The lifespan of Styrofoam floats is typically 5 to 8 years, which makes the comparative underperformance of cover materials a significant issue.

Maeda Kosen has addressed this challenge by utilizing the fabric from their weather-resistant large sandbags, known as the “Two-Ton Bag.” This innovative product has a durability similar to temporary works lasting up to three years, even under rigorous conditions. The fabric is particularly resistant to ultraviolet light, which is a leading cause of plastic degradation.

Overcoming Challenges Through Innovation

The weather-resistant float cover has been designed to counter the limitations of its predecessors. While the Two-Ton Bag fabric is thicker and initially less compatible, careful consideration of dimensions and components has resulted in a fit comparable to standard options. The company has filed for patents and design registrations to protect its innovative findings.

By applying the high durability and strength of its construction materials to float covers, Maeda Kosen aims to protect the marine ecosystem while providing a long-lasting solution for oyster farmers.

Specifications and Availability

The newly developed weather-resistant float covers are compatible with 400L and 440L fishing floats, ensuring versatility for users. For other sizes, interested parties are encouraged to contact Maeda Kosen for inquiries. The company’s commitment to improving infrastructure and environmental health is further reflected in this initiative, showcasing how innovation can address pressing ecological issues.

About Maeda Kosen Co., Ltd.

Founded in 1972, Maeda Kosen has grown into a comprehensive provider of geo-synthetics, engaging in the manufacturing and sales of civil engineering materials and various industrial materials. The company contributes to regional safety and security, as well as building more disaster-resilient infrastructure, reinforcing their commitment to enhancing society and the environment.

Topics Environment)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.