Tokyo Metro Achieves Groundbreaking Aluminum Recycling Innovation in Subway Cars

Introduction

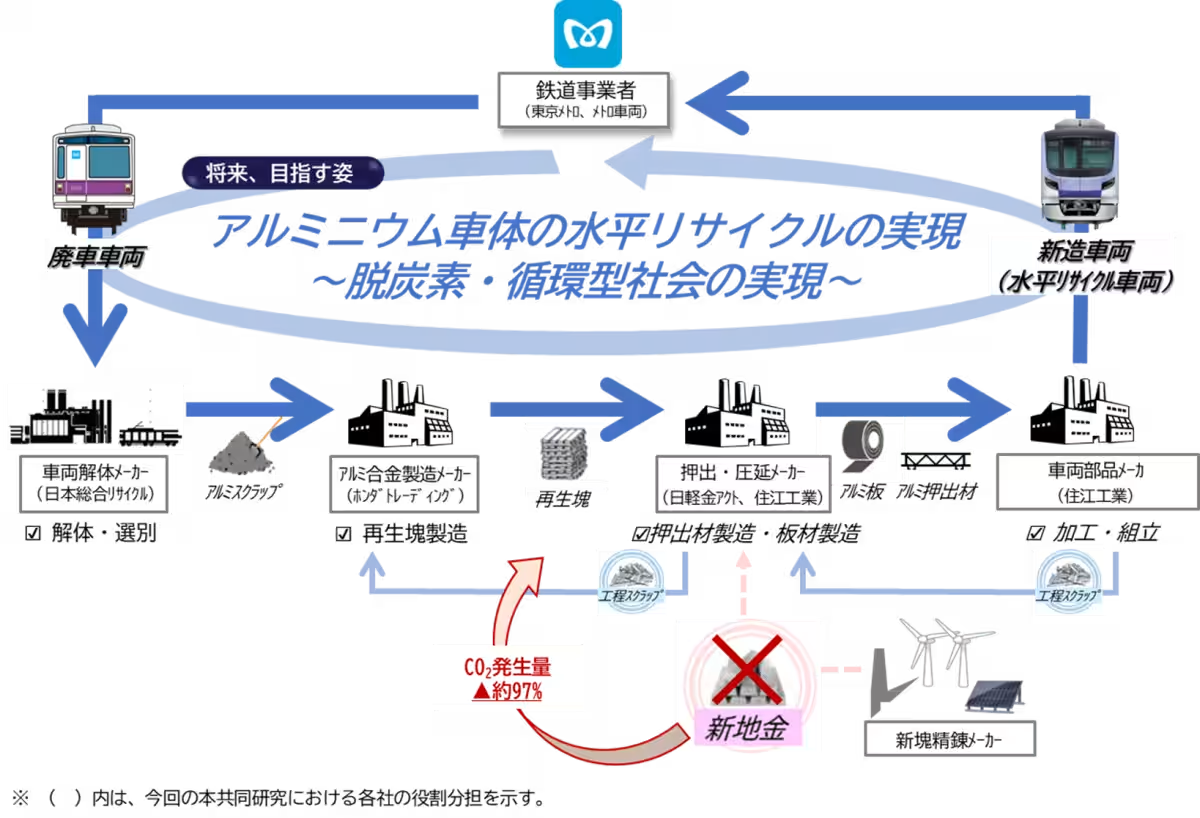

In a significant step towards sustainability, Tokyo Metro has achieved the first-ever horizontal aluminum recycling in Japan's subway cars. This groundbreaking initiative involves a collaborative effort among several companies, including Tokyo Metro, Metro Vehicle Corporation, Honda Trading Co., Ltd., and others, who have successfully recycled aluminum components from decommissioned 8000 series trains into new 18000 series trains. The project not only targets recycling but also aims at reducing the carbon footprint associated with aluminum production, marking a new era for eco-friendly practices in public transportation.

The Importance of Aluminum Recycling

Aluminum production is notoriously energy-intensive, contributing to considerable CO2 emissions. With global climate change concerns mounting, the initiative undertaken by Tokyo Metro demonstrates a commitment to environmental responsibility. By recycling aluminum without degrading its quality, substantial reductions in carbon emissions can be achieved; it is estimated that about 97% of CO2 emissions can be avoided compared to manufacturing new aluminum.

Project Overview

The joint research commenced in FY2024 focuses on horizontally recycling aluminum using aluminum alloy from decommissioned 8000 series subway cars. The process involves carefully sorting aluminum scrap by alloy type, effectively maintaining its purity without degradation. The end goal is to utilize this recycled material in the interiors of newly produced trains, thus contributing to a circular economy.

Key Steps in the Recycling Process

1. Deconstruction and Sorting: The initial phase involves dismantling the decommissioned trains, removing non-aluminum elements such as steel and plastics. The remaining aluminum is sorted into different alloy grades (5000 and 6000 series) to ensure quality for further processing.

2. Recycling Materials Production: The sorted aluminum scrap undergoes melting to remove impurities, leading to the creation of high-quality aluminum sheets and extrusions suitable for interior components of new trains.

3. Production of Train Components: Finally, the recycled materials are utilized to manufacture specific components for the new 18000 series trains, including parts for seating areas and side panels.

Results Achieved

The initiative not only demonstrates the feasibility of aluminum horizontal recycling but also verifies that the quality of recycled materials meets the necessary standards for passenger train components. The project has successfully reduced CO2 emissions by approximately 8 tons during the manufacturing of these parts, significantly benefitting the environment.

Future Prospects

Looking forward, Tokyo Metro aims to expand the range of its aluminum recycling efforts. This may include strengthening the quality management of components like structural frames, which have higher demands for durability and safety. Insights gained from the current project will guide these advancements, allowing for greater application of recycled materials and further reductions in CO2 emissions.

Community Engagement

To promote this innovative recycling method, Tokyo Metro plans to display educational PR stickers within the newly produced trains. These stickers will outline the recycling process - from decommissioned cars to new train components - effectively raising public awareness about the importance of recycling in reducing environmental impact.

Conclusion

The collaboration between Tokyo Metro and its partners signifies a monumental shift in the public transportation sector towards sustainable practices. By adopting innovative recycling techniques, they are not only contributing to the creation of a circular economy but also setting a benchmark for other industries to follow. This commitment paves the way for a greener future, underscoring the role of public transport in addressing climate challenges and promoting sustainability in urban environments.

Topics Environment)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.