MOLDINO Unveils New EPVF-ATH End Mill for Precision Finishing

MOLDINO's New EPVF-ATH End Mill: Revolutionizing Precision Finishing

MOLDINO, headquartered in Sumida, Tokyo, is excited to announce the launch of the EPVF-ATH, a cutting-edge end mill designed for precision finishing in machining processes. Scheduled to be available from April 21, 2025, this innovative tool addresses the evolving demands of industries that utilize large molds, particularly in aluminum die-casting.

Development Background

In recent years, there has been a significant advancement in the development of large molds, prominently demonstrated through products like Gigacast. This has led to an increased demand for deeper machining processes. MOLDINO has recognized that many machining operations require the use of tools without the worry of potential interference. To address this, the company developed a range of tools featuring a free neck design aimed at reducing interference risks and enhancing tool consolidation, which started launching between 2024 and 2025.

In addition, traditional finishing machining often involves contour-based processes, which can create notable challenges when it comes to removing step differences originating from rough machining, particularly in deep areas where the tool projection length is L/D = 20 or more. These challenges necessitate significant additional labor in subsequent polishing stages. To counter this issue, MOLDINO has introduced a new machining method, “reciprocating finishing machining,” along with the EPVF-ATH end mill specially designed for this technique.

Product Features and Advantages

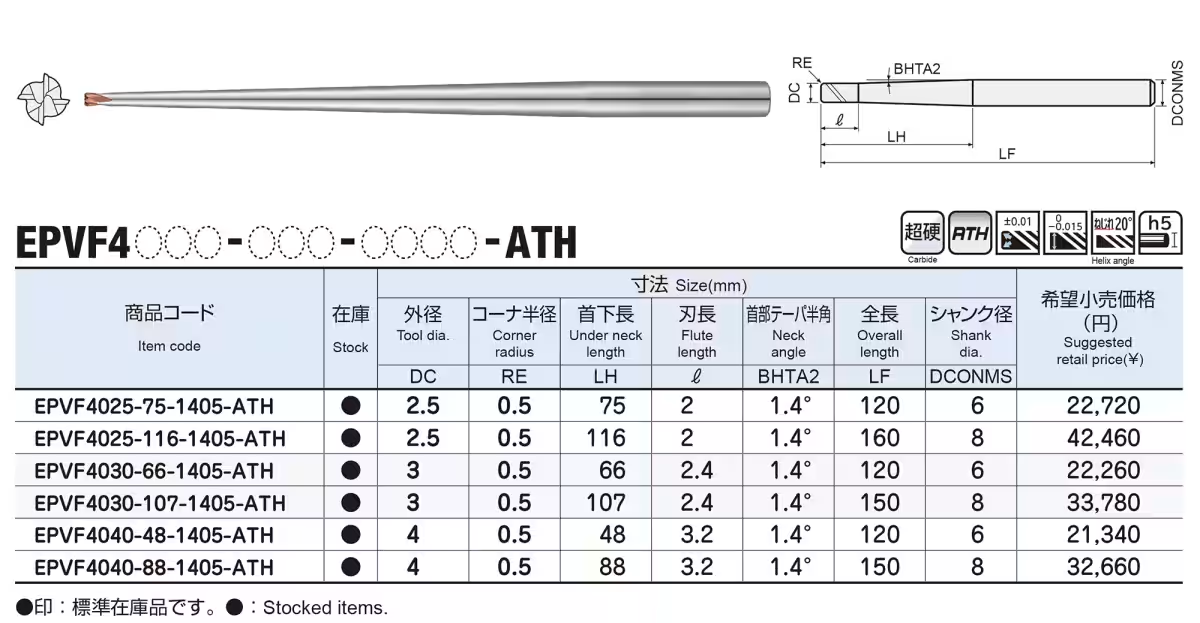

The EPVF-ATH is a carbide end mill with four cutting edges tailored specifically for the new reciprocating finishing process. Key features of the EPVF-ATH include:

- - Minimized Steps and Surface Marks: The end mill effectively reduces step differences during tool changes and minimizes lateral stripes produced during the machining process. This significantly shortens polishing time after finishing.

- - Free Neck Design: Each item in the range incorporates the free neck configuration, eliminating step differences at the neck, reducing the risk of interference with wall surfaces, and allowing for adjustable gripping lengths, making it versatile for various depths.

- - Seamless Zero-Corner Cutting: Utilizing a seamless blade connection between the peripheral and corner R blades ensures stable surface conditions during machining, while a design reducing axial vibration through a mild twisting angle on the peripheral cutting edge enhances overall performance.

- - Strong Back Taper: The EPVF-ATH is designed with a robust back taper that prevents unnecessary contact with peripheral edges during deep machining, contributing to improved stability.

Recommended Applications

This new end mill is particularly suitable for the reciprocating finishing of deep angled wall surfaces in various molds.

Specifications

- - Tool Diameter: Available in sizes ranging from Φ2.5 to Φ4 (6 items)

- - Pricing: The EPVF-ATH is priced between ¥21,340 and ¥42,460 (tax excluded).

Product Launch Date

The EPVF-ATH will officially launch on April 21, 2025.

For more information, visit MOLDINO Product Details.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.