Revolutionizing Recycling: Refineverse Group Develops RENAMY from Used Rubber

A Leap in Sustainability: Introduction of RENAMY

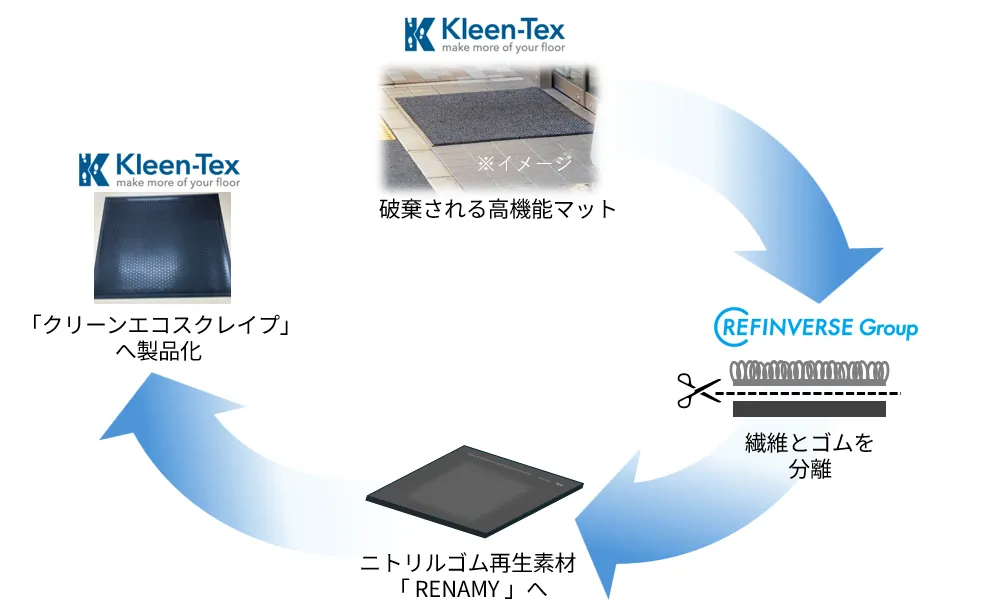

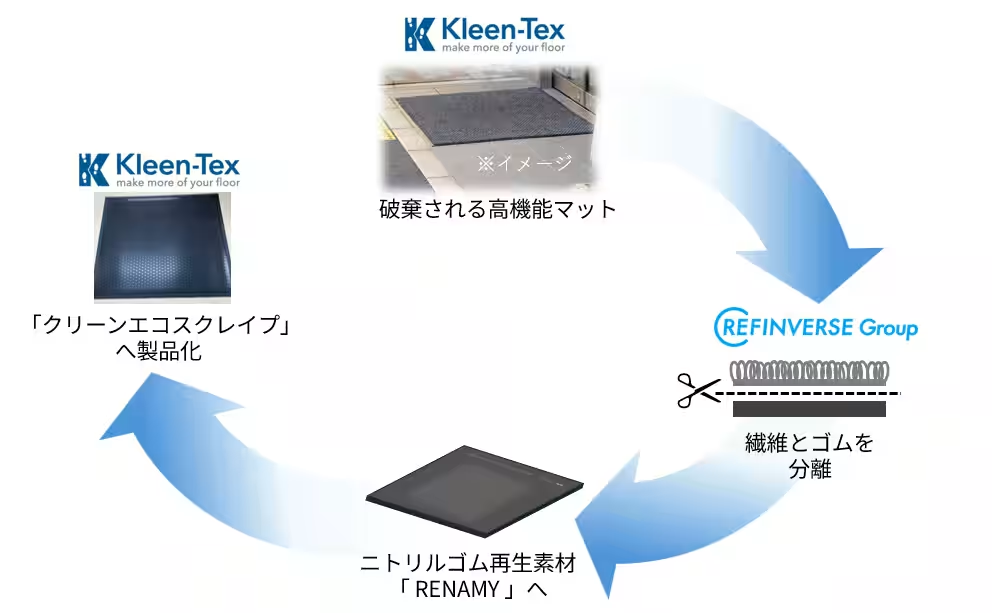

In a groundbreaking move for sustainability, Refineverse Group, based in Tokyo, and Cleantex Japan from Kobe have joined forces to unveil a pioneering recycled material known as RENAMY. Engineered from used nitrile rubber (NBR) originally utilized in dust-control mats, RENAMY signifies a remarkable advancement in recycling technology and material reuse within the industry.

Background on RENAMY Development

Since its inception, Refineverse Group has been at the forefront of implementing circular economy strategies. This innovative firm has established advanced recycling techniques focused on repurposing discarded materials into high-quality products. For example, the company has successfully driven initiatives involving recycled nylon pellets from waste fishing nets and airbags, thus contributing significantly to resource recovery.

On the other hand, Cleantex Japan has made a name for itself in the production and sales of high-performance mats over the years. However, the complexity of separating rubber components from the textile fibers embedded within dust-control mats has posed significant challenges, leading to approximately 800 tons of mats being disposed of annually. Recognizing the environmental impact, Cleantex partnered with Refineverse to explore sustainable alternatives and sought to implement CO₂ emission reduction strategies. Their collaborative efforts gave rise to the RENAMY project, a pivotal advancement in creating a more sustainable future.

RENAMY: An Innovative Material

The new material RENAMY is created through a meticulous process that separates the rubber from the textile fibers in the dust-control mats. By focusing on the material recycling of nitrile rubber, RENAMY emerges as an industry-first solution that transforms waste into valuable resources. This innovation not only allows for higher ratios of recycled material compared to existing alternatives but also contributes to significant reductions in environmental burdens, pushing us closer to a circular economy.

Once the used mats are collected by Cleantex Japan, they are transported to Refineverse's facility in Chiba for the recycling process. The resulting rubber material is then reintegrated into the production of high-performance mats under the brand name “Clean Eco Scrape.”

Furthermore, there are plans to leverage RENAMY's properties in the development of additional rubber products, targeting a significant reduction in both waste generation and CO₂ emissions, while promoting sustainability across various sectors.

Clean Eco Scrape: New Market Launch

The premium mat, Clean Eco Scrape, made from RENAMY, is set to be launched in early December 2025, targeting the outdoor mat segment for the retail market. Additionally, Cleantex aims to gradually expand its conventional pile mats featuring this innovative material to address varied market demands. Future initiatives also include adapting RENAMY as a backing material for rental mats, enhancing their commitment to sustainable product development.

Looking Ahead

Both Refineverse Group and Cleantex Japan are determined to accelerate their initiatives, striving to implement recycled materials across a broader range of high-performance mats and related products. Their ultimate goal is to enhance recycling rates for business mats and establish a pioneering recovery scheme that fosters a sustainable, circular economy.

About Refineverse Group

With a mission of connecting future wealth through unique perspectives and technologies, Refineverse Group has been a pioneer in circular economy practices for over 20 years. Alongside their projects in recycling carpet tiles and developing biodegradable materials, including new bio-materials like ReFEZER (derived from bird feathers), they are continuously expanding their research and operations to fulfill their vision of a sustainable society.

With the launch of RENAMY and its future applications, both companies are paving the way for a more sustainable future, reinforcing the significance of innovation in battling environmental challenges.

Topics Environment)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.