Innovative Process Developed for Extracting Antimony from Solar Panel Glass

New Method for Antimony Recovery from Solar Panel Glass

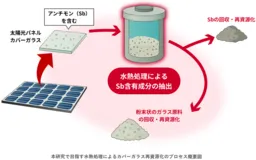

In a significant advancement aimed at addressing the upcoming challenges related to the disposal of solar panels in the late 2030s, a research team from the National Institute of Advanced Industrial Science and Technology (AIST) has developed a method to extract antimony from the cover glass of solar panels. This initiative, undertaken in collaboration with Chubu Electric Power Company, highlights the importance of recycling rare elements that enhance the efficiency of renewable energy technologies.

As many solar panels reach the end of their service lives around the late 2030s, a substantial amount of cover glass will require disposal. Traditionally, antimony is added to this glass to improve its transparency. Hence, as the industry prepares for an influx of decommissioned panels, the need for efficient recovery methods of antimony from used cover glass has become a pressing concern.

The research team, led by Kenichi Mimura, Ryuutarou Wakabayashi, and Fumihiko Ohashi, employed a hydrothermal treatment process to achieve this. This innovative technique utilizes the specific phenomenon where antimony does not incorporate into the crystalline structure during the crystallization of glass. By controlling the temperature and utilizing hydrothermal processing within optimal ranges, they successfully extracted approximately 80% of antimony content from the glass powder through extensive testing and analysis.

The glass powder analyzed via fluorescent X-ray (XRF) demonstrated promising results, yielding significant quantities of antimony for potential recycling. With approximately 80% of the metal extracted, this method not only signifies an effective remediation strategy but also lays the groundwork for further technological advancements in the recycling sector.

The implications of this research extend beyond mere extraction. As solar power installation has surged since around 2010, these technologies now face the inevitable challenge of large-scale disposal. The establishment of energy-efficient recovery techniques aligns with government initiatives for creating a circular economy, which is crucial for sustainable environmental practices. The project's long-term vision aims to excavate the complexities surrounding the extraction mechanisms and enhance the efficiency of the overall process, thereby contributing significantly to the recycling of critical materials.

The AIST team's findings will be showcased at the Chubu Electric Power Company’s Techno Fair 2025, scheduled for October 30-31, 2025. Through this event, the team hopes to foster further discussions on sustainable practices and innovative solutions within the renewable energy landscape.

Research Background and Methodology

The cover glass of solar panels is typically treated with antimony oxide (Sb2O3), which helps prevent bubble formation during production, enhancing clarity. As an essential component, the extraction and recycling of antimony face hurdles, especially as the industry gears up for mass disposal in the coming years. Past attempts at recovering this element have yielded varying results but lacked the efficiency and practical applicability needed for broad adoption.

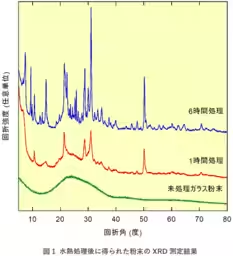

The present study explored various hydrothermal conditions to maximize antimony extraction. Used solar panels were dismantled and ground into powder, which was then boiled with water in a sealed container, maintaining temperatures below standard pressure cooker specifications for periods ranging from one to six hours. Following the hydrothermal process, the mixture was separated into liquid and solid phases through centrifugation.

The extraction rates were assessed based on the analysis of Sb2O3 content relative to silica (SiO2), revealing a notable increase in extraction efficiency with prolonged processing times. The scientists confirmed the crystallization of the glass and the consistent release of antimony during treatment, indicating that this method is both feasible on an industrial scale and conducive to high-efficiency extraction.

Future Directions

Looking ahead, the research team plans to deepen their understanding of the extraction mechanics to further refine the process's efficiency and scalability. The ability to recycle antimony from electronic waste represents a crucial step toward a sustainable future in energy. The anticipated success of these endeavors could contribute significantly to environmental conservation and resource management, paving the way for sustainable practices across multiple industries.

By developing such a method, this research plays a vital role in promoting a circular economy in electronics, addressing both current and future challenges posed by electronic waste. The rise of renewable energy technologies will undoubtedly require innovative solutions like these to ensure resources are responsibly managed and reused, solidifying the importance of research in advancing eco-friendly initiatives.

Topics Environment)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.