Ethos AI Revolutionizes Manufacturing Estimation and Design Processes with Intelligent Automation

Ethos AI: Pioneering Automation in Manufacturing Estimation and Design

In the realm of manufacturing, the effectiveness and efficiency of estimation and design processes heavily depend upon the handling of technical drawings. These drawings often serve as the foundation for crucial tasks such as creating estimates, verifying designs, and ensuring quality control. However, reading technical drawings and confirming specifications requires an advanced level of expertise, leading to a reliance on the experience and judgment of individuals, which can often become a bottleneck in production.

As companies grapple with a shortage of skilled technicians and the increasing complexity of tasks, several critical challenges have emerged:

- - Extended time for estimation

- - Increased burden of verifying drawings and specifications

- - Underutilization of past drawings and established design rules

Particularly, the manual processes involved in extracting numerical data and components from drawings to input into spreadsheets are fraught with high error risks and demand considerable labor. Despite the clear need for efficiency, many manufacturing entities are still employing these outdated practices.

Revolutionizing the Workflow

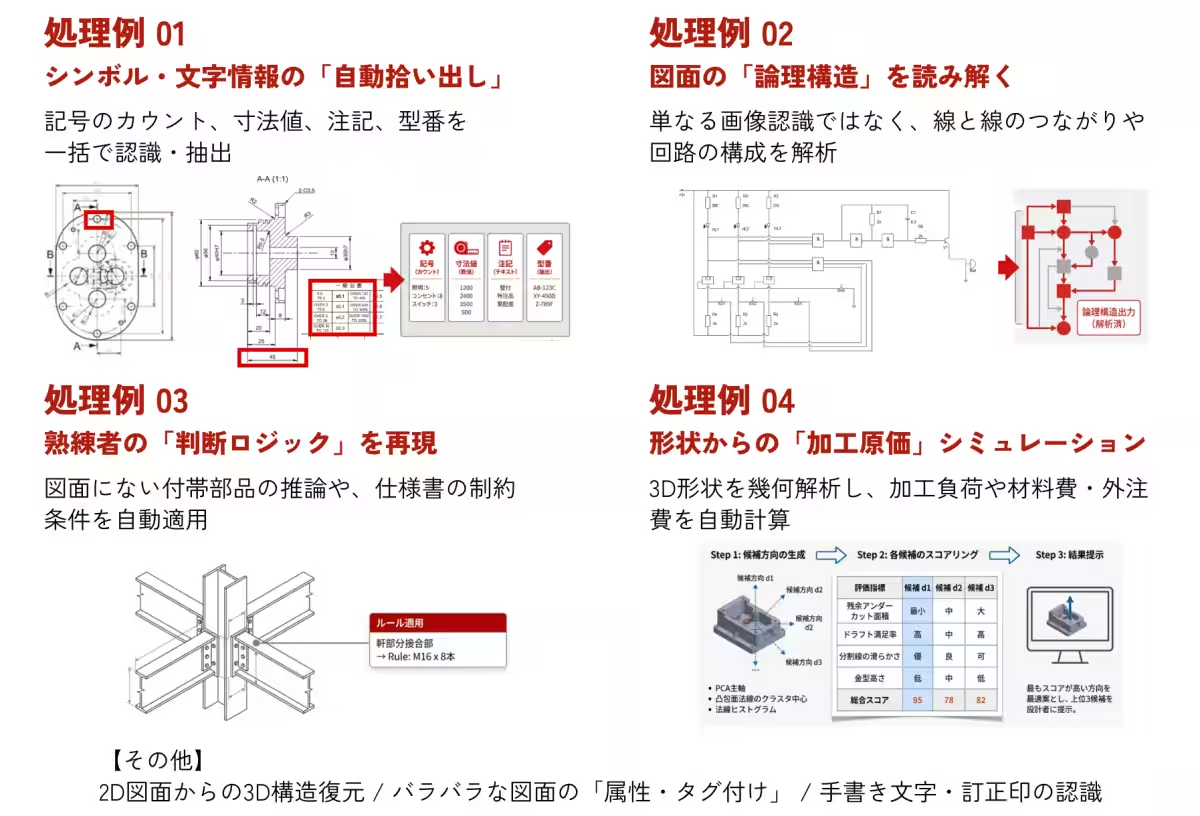

To address these pressing issues, Ethos AI has embarked on an initiative centered on the intelligent automation of workflows that originate from technical drawings. This solution employs cutting-edge AI capable of interpreting both 2D and 3D CAD data, effectively analyzing PDF drawings to automate and streamline tasks that are otherwise prone to being dependent on individual expertise.

Rather than aiming for a wholesale automation of all estimation, design, and quality assurance activities, Ethos AI’s approach involves breaking down these tasks into manageable components:

1. Extracting information from drawings such as symbols, dimensions, and notes.

2. Verifying consistency among drawings, specifications, and internal rules.

3. Providing automated decision support based on JIS standards and design criteria.

4. Facilitating the extraction of components and creation of Bills of Materials (BOM).

5. Assisting estimation tasks with consideration for specific conditions.

By methodically addressing each segment of the process, Ethos AI aims to pinpoint which operations can be effectively replaced by AI versus those that still require human oversight and judgment.

In the initial phase, the company provides a hybrid Business Process Outsourcing (BPO) model combining automated processing by AI with manual verification steps, ensuring accuracy while minimizing the implementation burden on teams.

Automating Estimates: The Practical Approach

The strategy for automating estimation focuses not on completely replacing the human element but enhancing it by applying AI at task-specific levels:

- - Picking, inputting, and aggregating data from drawings.

- - Reflecting specific conditions in estimates.

This targeted implementation allows manufacturing teams to seamlessly integrate AI into their existing workflows without causing disruption.

Anticipated Outcomes

Ethos AI's initiative is expected to yield substantial benefits, including:

- - Reduction in labor hours for extracting, inputting, and aggregating data from drawings.

- - Shortened lead times for estimates and design checks.

- - Minimized human errors.

- - Decreased dependency on veteran personnel.

- - Reactivation of past drawings and established design rules.

Instead of merely automating tasks, the focus is on re-engineering processes in a way that honors the insights and decisions of operational teams, paving the way for sustainable systems that will be genuinely valued in the long term.

Target Audience

Ethos AI's services are particularly geared towards firms that:

- - Struggle with extensive time requirements for data extraction and aggregation from drawings.

- - Experience dependency on veteran staff for completing estimation and design checks.

- - Find the verification of drawings, specifications, and company rules to be an overly complicated process.

- - Feel constrained by a lack of technicians, affecting their responsiveness and design speed.

Industries such as wire harnesses, control panels, and assembly of equipment/components—which necessitate drawing-based estimation and design judgment—are key beneficiaries of this AI integration.

Future Outlook

Looking ahead, Ethos AI aims to further leverage AI technologies in the manufacturing sector to enhance the efficiency and standardization of estimation, design, and quality assurance tasks linked to drawing activities. The goal is to transcend beyond basic automation, targeting the alleviation of individual dependencies and fostering intergenerational knowledge transfer.

For more information about Ethos AI and its contributions to automating manufacturing processes, visit Ethos AI.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.