Innovative Smartphone System 'Sakutto Scan' Now Compatible with iPhone

Innovative Smartphone System 'Sakutto Scan' Now Compatible with iPhone

The work performance collection system 'Sakutto Scan' by Inproove is set to revolutionize factory operations by enhancing accessibility with its compatibility with iPhones. This groundbreaking tool will be showcased at the Manufacturing World Osaka event, held from October 1 to 3, 2025, at Intex Osaka, giving industry professionals a firsthand look at its capabilities.

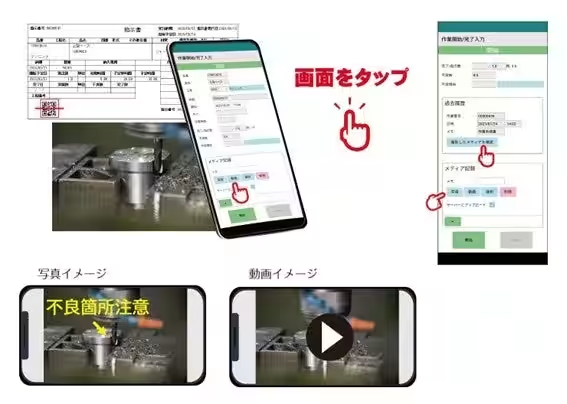

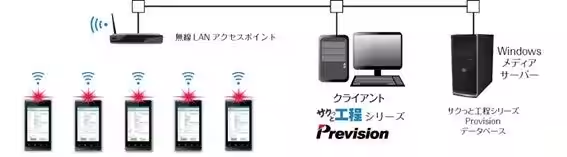

The 'Sakutto Scan' system is designed to collect work performance data simply by scanning barcodes on work instructions with a smartphone camera. This tool integrates seamlessly with Inproove’s production management system, 'Prevision,' or the 'Sakutto Process' series, optimizing the workflow and data accuracy.

Enhanced Compatibility

With over 50% of smartphone users in Japan opting for iPhones, the recent update allowing iPhone support is a significant step forward. Manufacturers can now use a familiar device to enhance the functionality of 'Sakutto Scan,' making it an indispensable tool in production environments.

Ideal for workplaces that engage in customized processing and assembly or repetitive processing of similar specifications, 'Sakutto Scan' boasts several advantages over traditional handheld terminals:

1. Ease of Use: Users can enter performance data directly from anywhere using a smartphone, eliminating the need for cumbersome additional setups.

2. Real-Time Data Collection: Workers can view relevant information on their smartphones and log work hours and quantities with just a few taps, minimizing errors and enhancing efficiency.

3. Cost-Effective Implementation: With initial software costs as low as ¥200,000 for the first unit and ¥20,000 for additional licenses, companies can allocate technology resources wisely without incurring excessive expenses.

Key Benefits of Using 'Sakutto Scan'

1. Anywhere Input of Work Performance Data

Thanks to its wireless LAN capability, users can access the server directly via smartphone, without complicated wiring or installation procedures. This flexible setup allows for convenient data entry right from the production floor, reducing the risk of missed records and ensuring accurate information gathering.

2. Real-Time Monitoring

The server displays the necessary product and lot information on the smartphone, allowing operators to confirm details and quickly log their work in real-time. This immediate feedback loop helps prevent delivery delays and enables instant comparison of completed work against planned resources, ultimately boosting productivity.

3. Affordable Implementation Costs

With software pricing as stated above, even assigning one device per worker remains financially manageable. The direct data input system reduces unnecessary labor time, resulting in swift investment recovery thanks to improved operational efficiency.

Optional Media Functionality

Among the notable features is the optional 'Media Function,' which allows users to attach photos and videos to specific items. This advanced method of communication is particularly useful in cases of non-conformities, facilitating real visual references instead of relying on written notes or sketches that can easily lead to misunderstandings.

Utilizing the media functionality, teams can efficiently share crucial visual information during production, decreasing the likelihood of recurring issues with known defects—a key strategy for continuous improvement in manufacturing.

Leverage IT Subsidy for Enhanced Factory Systems

The 'Sakutto Scan' system can be used as an added feature of the production management software 'Prevision,’ which qualifies for the IT adoption subsidy for 2025. This governmental support allows companies to receive up to ¥3,500,000 in funding, significantly alleviating the usually steep cost of system installation.

By effectively utilizing the subsidies, businesses can enhance visibility in their operations and improve efficiency without substantial financial burden. Inproove also offers application support for these subsidies, ensuring partners feel confident navigating the approval process without hesitation.

In conclusion, combining 'Prevision' and 'Sakutto Scan' alongside subsidy support paves the way for manufacturers to bolster productivity while minimizing overhead costs. For more information on these innovative solutions, please visit the Prevision product page and the Sakutto Scan product page.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.