Revolutionizing Japan's Industry and Healthcare with AI-Edge Computing and 5G Technologies

Enhancing Industrial and Healthcare Efficiency with AI and 5G

Inhand Networks, renowned for its high-reliability AI-edge computing and industrial IoT solutions, is revolutionizing Japan's manufacturing, smart cities, and healthcare. By addressing critical challenges in accuracy, latency, and safety, Inhand is facilitating the transition to Industry 5.0 and the rapid digitalization of the healthcare sector. The company aims to build sustainable and robust partnerships with Japanese enterprises, enhancing both market presence and technical influence.

1. AI Edge Computing Solutions

A. AI Product Inspection Solution

Inhand’s AI product inspection solution is designed to resolve customer challenges through a structured approach:

1. Customer Requirements:

- Manual inspections are inefficient and challenging for quality control.

- There is a lack of local processing capacity, raising data security concerns.

- A demand for an open platform that separates software and hardware due to a diverse ecosystem of algorithms.

2. Solution Topology:

- Edge Devices: Compatible with various brands and industrial cameras, enabling the detection of dimensional deviations, scratches, and foreign materials.

- Core Processing Unit: The EC5550 AI edge computer, positioned near production equipment, connects to industrial cameras for high-speed processing of high-resolution images and supports third-party AI algorithms for image recognition and defect judgment.

- Data Transmission and Management: Processing results are uploaded via wired, Wi-Fi, or 5G connections to local inspection servers or cloud platforms, enabling centralized management and traceability while integrating quality data storage.

- Solution Features: Efficient use of edge computing capabilities without affecting existing production line layouts, while providing a stable, efficient, and safe smart inspection platform.

3. Strengths and Value:

- With AI performance of up to 100 TOPS, it supports real-time processing of high-resolution images and multiple-stream inspections.

- The Linux-based open architecture allows for flexible deployment of both in-house and third-party AI models.

- Strong security through TPM 2.0 ensures reliable data processing, completing image analysis at the edge to minimize latency, bandwidth load, and ensure data privacy.

B. AI Traffic Management Solution

The AI traffic management solution converts video into intelligent data through object detection, recognition, classification, and event analysis. Utilizing edge AI for real-time video analysis, it identifies moving objects on the road accurately and seamlessly transmits the results to a data management platform for real-time monitoring and historical analysis, enhancing traffic management decisions.

2. Factory DX & Predictive Maintenance Solutions

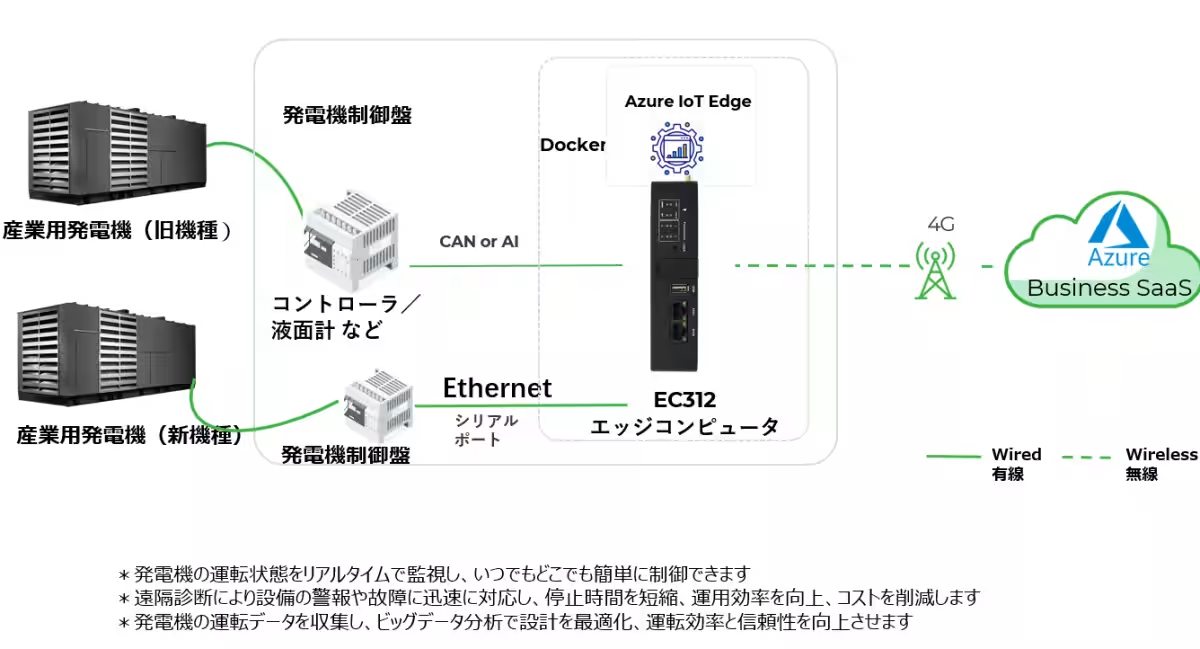

A. Predictive Maintenance for Industrial Generators

1. Customer Requirements:

- Real-Time Monitoring: Continuous monitoring of key parameters like temperature, vibration, voltage, and current through a sensor network.

- Remote Fault Diagnosis: Edge computing allows for swift fault determination at the site during anomalies, minimizing communication delays while achieving accurate diagnoses.

- Predictive Maintenance: Utilizing historical data and machine learning models helps predict potential issues ahead of time, reducing downtime and maintenance costs through planned interventions.

- Remote Control and Alerts: Ensures secure remote operations via the cloud for startup, shutdown, and output adjustments, along with immediate alerts sent via email, SMS, or app notifications when anomalies are detected.

2. Solution Topology:

- Built around the EC312 edge computer, connecting various sensors, generator controllers, and remote monitoring platforms, including the DeviceLive cloud management foundation.

- The EC312 interfaces with controllers and sensors via Ethernet, serial, and DI/DO, actively collecting and preprocessing status data, sending it to monitoring platforms through cellular communication.

3. Strengths and Value:

- Supports various programming languages, allowing freedom in application development tailored to on-site requirements without limitations in functionality.

- Features abundant interfaces for data collection, adapting to diverse generator management needs.

- Ensures stable communication with multi-network connectivity, eliminating instability from geographic conditions.

- Enhances operational and maintenance efficiency through remote management capabilities.

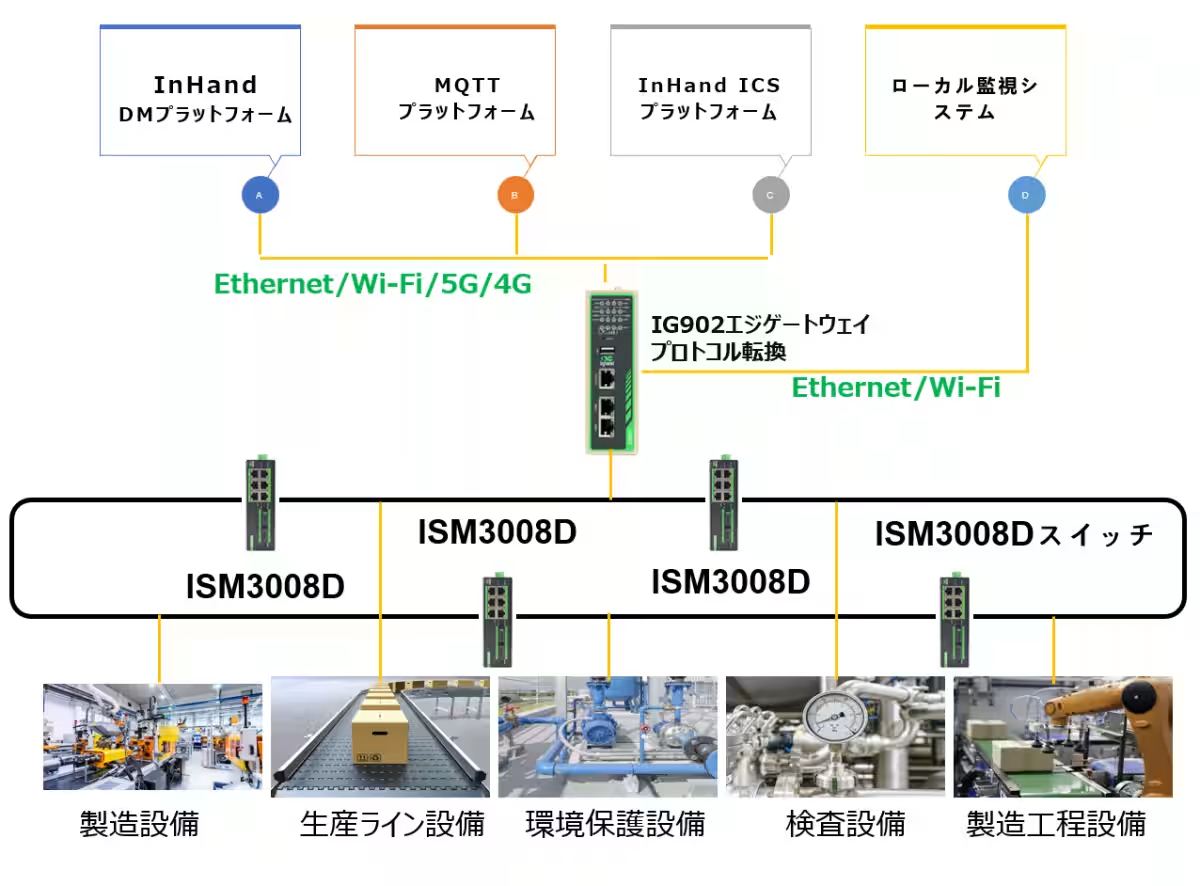

B. Digitalization and Visualization in Factories

Inhand’s equipment health management system oversees and maintains the entire lifecycle of industrial equipment, including operational monitoring, fault diagnosis, health status evaluation, maintenance records, and asset traceability. The system enhances equipment stability and safety, ultimately reducing operational costs for businesses. At the equipment level, Inhand utilizes industrial switches and edge gateways to gather multi-source heterogeneous data, digitalizing machinery efficiently.

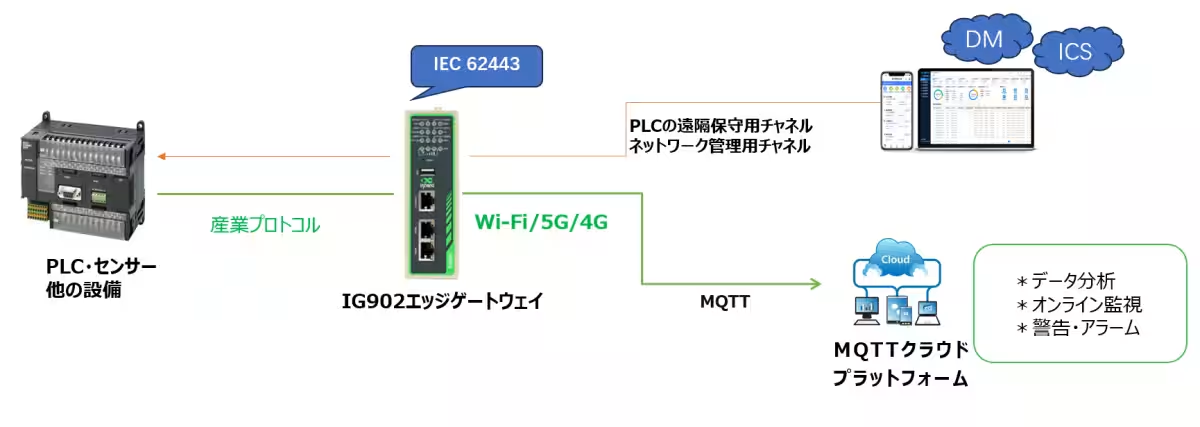

C. Smart Factories and Remote Monitoring Solutions

1. Customer Requirements:

- Real-time visualization and remote management to efficiently track equipment status and KPIs.

- Early detection of abnormalities to allow preemptive maintenance, reducing downtime and enhancing reliability.

- Data-driven decision support with systematic data collection and export capabilities to boost operational analysis and optimizations.

2. Solution Topology:

- Involves automation devices (PLC), an edge gateway with communication functions (IG902), and an IoT cloud platform.

- The IG902 captures critical data in real time and transmits it for remote management, while maintenance personnel can adjust settings through the InHand InConnect platform.

3. Strengths and Value:

- High-speed, stable networks: Supports LTE, Wi-Fi, and wired connections to prevent communication disruptions with multi-redundancy.

- Compatibility with major industrial protocols allows for easy implementation of remote monitoring and preventive maintenance.

- Custom development options using Python for specialized functions.

- Ideal for large-scale management with centralized gateway management through web GUI.

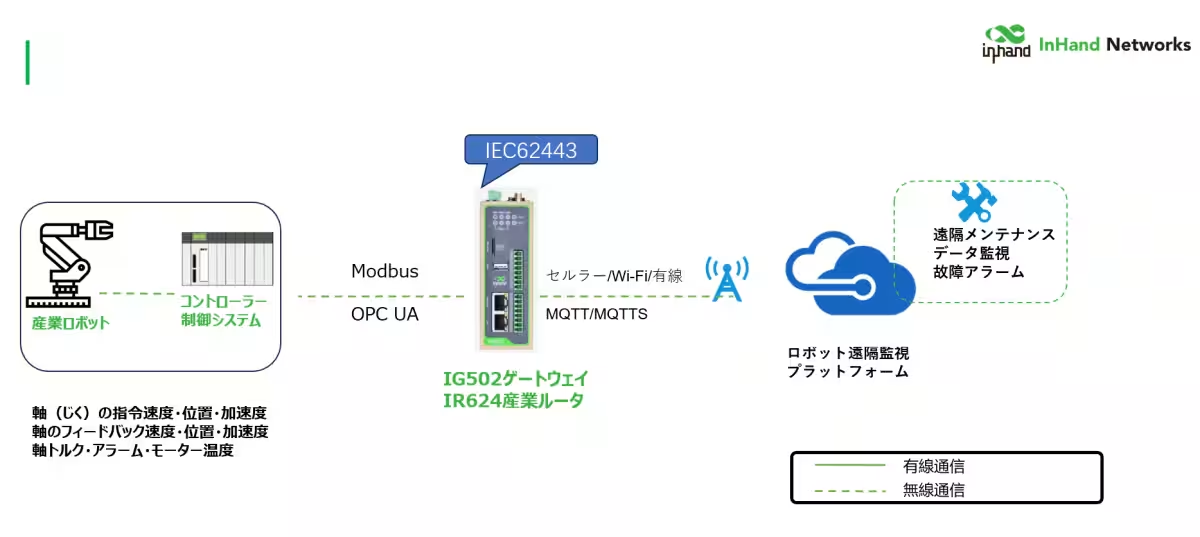

D. Remote Monitoring for Industrial Robots

This solution provides:

- Global cellular capabilities ensuring stable connections anywhere.

- Dual SIM redundancy for reliable communication continuity.

- VPN support for secure and reliable data transmission.

- A significant reduction in operational burden, allowing customer teams to track robot statuses effectively and provide safe, efficient remote maintenance.

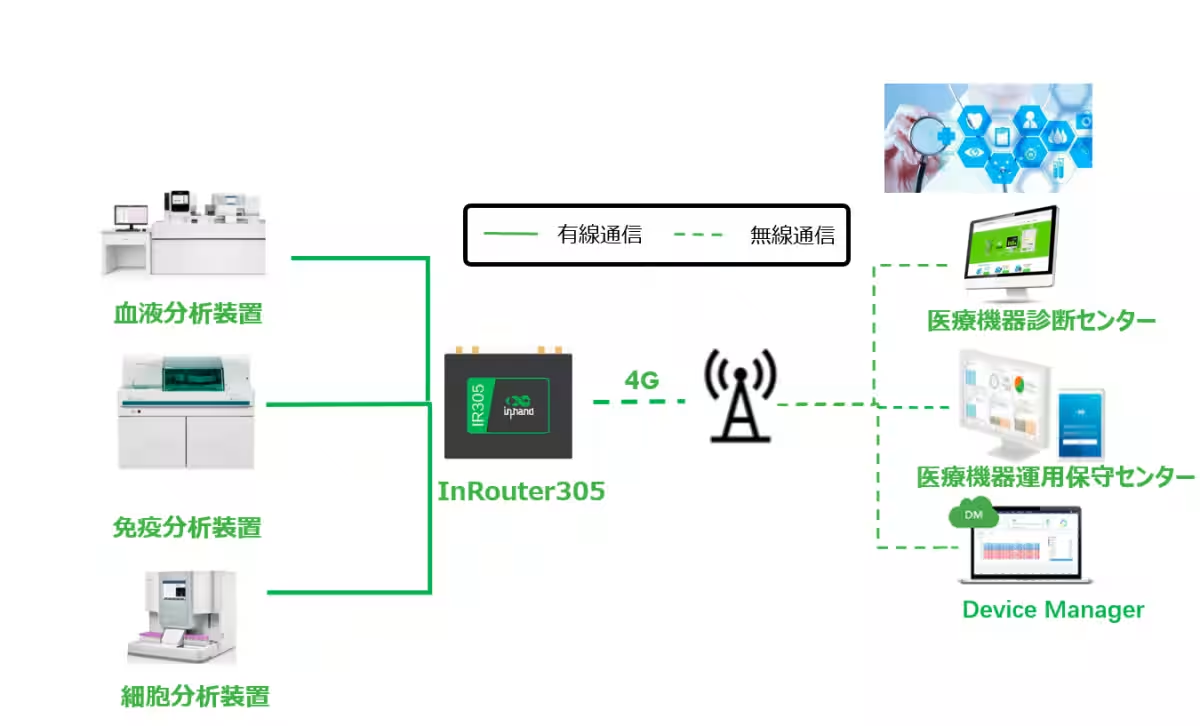

3. Medical Digitalization

A. Remote Maintenance of Medical Devices

1. Customer Requirements:

- High reliability and uninterrupted network connections.

- Comprehensive data security protocols.

- Easy centralized management for remote device operations across multiple locations.

2. Strengths and Value:

- The IR305 with Device Manager offers a secure and stable network for in vitro diagnostic medical devices, significantly improving service quality and user experience.

- Supports multiple device connections simultaneously through a 5-port design and utilizes global cellular solutions to ensure stable network access.

- Provides multi-layer security to ensure high communication safety, while automatic reconnect functionality maintains network continuity.

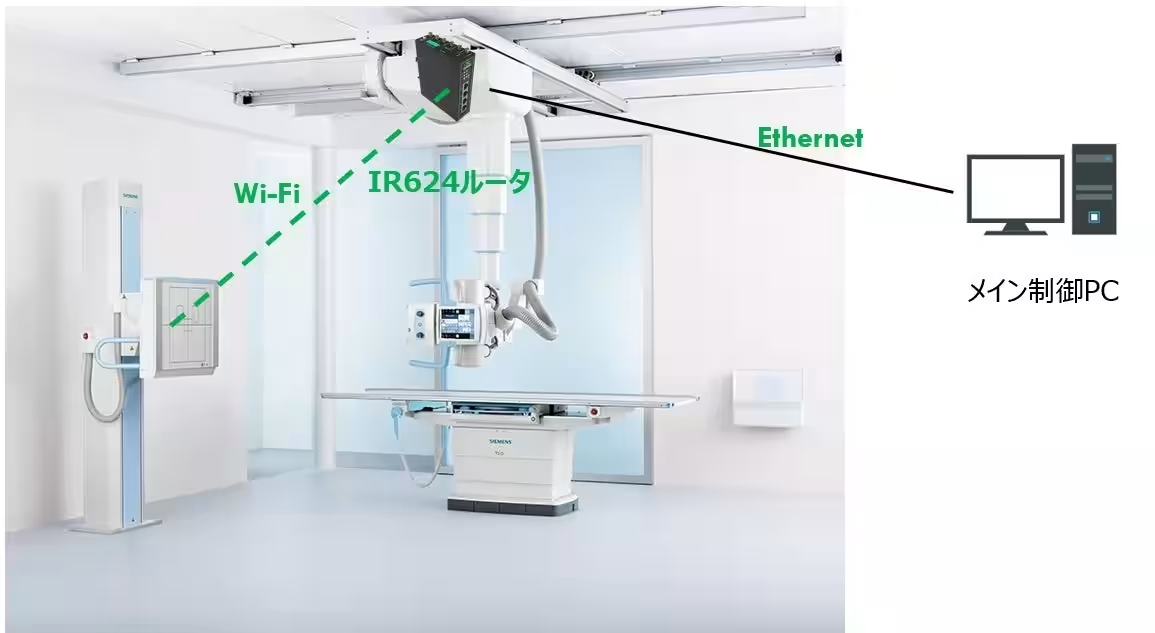

B. Network Solutions for DR Imaging Systems

1. Customer Requirements:

- Traditionally, DR imaging systems suffer from information silos that hinder diagnostic efficiency. Urgent implementation of high-performance network solutions is crucial.

- Key requirements include cellular and Wi-Fi networks, performance stability, and robust industrial-grade design.

2. Strengths and Value:

- The IR624 offers gigabit networks for real-time image data transmission, supporting physicians in their diagnostic tasks.

Future Prospects

Japan faces a pressing need to accelerate digital transformation due to workforce shortages and aging infrastructure. The automation of quality inspections and predictive maintenance is crucial for maintaining competitiveness in manufacturing. Meanwhile, the healthcare sector is entering a new phase with the integration of 5G technology for telemedicine and imaging diagnostics. Real-time data will increasingly become pivotal for enhancing safety and operational optimization in transportation and infrastructure. Under these market conditions, AI-edge computing stands as an essential technological foundation for Japanese enterprises prioritizing reliability in their industrial and healthcare digital transformation.

Product Applications

These solutions have been adopted across various scenarios in digital factories, healthcare, power and new energy, and smart cities, demonstrating excellent stability and reliability. They have garnered high trust from major domestic and international companies, including State Grid Corporation of China, Southern Power Grid, Mitsubishi Electric, Yaskawa Electric, GE, Schneider Electric, ABB, Siemens, and GE Healthcare.

For inquiries, please reach out to:

Luo Jie

Asia-Pacific Sales Department

Inhand Networks, Inc.

14F Pacific Finance Building, 1777 North Section Tianfu Avenue, High-tech Zone, Chengdu, Sichuan, China

Email: [email protected]; Mobile: +86 13818323450

Web: www.inhand.com; https://www.inhand.com/jp/

Inhand Networks has received high acclaim from our clients across various sectors for our AI product inspection, traffic management, industrial DX, predictive maintenance, and healthcare DX solutions. We remain committed to contributing to the development of businesses in Japan.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.