Schneider Electric and Sony Semiconductor Solutions Launch AI Safety Solutions for Manufacturing

Enhancing Manufacturing Safety Through AI Collaboration

In an impressive move towards modernizing manufacturing safety, Schneider Electric has partnered with Sony Semiconductor Solutions to introduce an innovative AI-powered safety solution tailored for production environments. This collaboration harnesses Sony's intelligent vision sensor technology alongside Schneider Electric's industrial computing capabilities, marking a significant advancement in workplace safety protocols.

The Innovative Solution

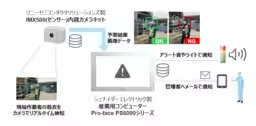

This new solution combines the intelligent vision sensor known as IMX500 from Sony, equipped with advanced AI processing capabilities, and Schneider Electric's Pro-face industrial computers, particularly the PS6000 series. Notably, the IMX500 sensor can process AI functions internally, negating the need for cloud connectivity. This streamlined approach allows for rapid implementation of AI systems directly on site, ensuring a swift response to safety challenges.

Prior to its launch, this AI safety solution underwent a successful test implementation at Schneider's Izumiotsu plant, a facility responsible for final assembly and bespoke customizations of Pro-face brand products. Within this plant, strict safety measures are enforced, requiring staff to wear safety gear such as helmets, safety shoes, and jackets in areas where hazards such as slips and falling objects are present. The integration of AI cameras equipped with the IMX500 allows for real-time monitoring of safety conditions. By utilizing the data captured through this system, alerts can be triggered when individuals enter hazardous areas without the necessary protective gear, thereby minimizing potential risks and enhancing overall safety management.

Key Features of the Solution

- - High Precision Recognition: The intelligent vision sensor automatically detects the wearing of essential safety equipment in real-time, ensuring compliance.

- - Integration with Industrial Computers: Detection results are instantly visualized and communicated through the HMI, allowing for immediate action.

- - Ease of Installation: The system's simplicity ensures that there is no need for complex wiring or extensive modifications, making it adaptable to various existing environments.

Future Prospects for the Solution

The partnership between Schneider Electric and Sony opens the door to a host of applications beyond just improving safety. This technology allows for low-cost, quick AI implementation across numerous manufacturing scenarios.

Scenarios for Utilization

- - Occupational Safety and Health: Continuous monitoring of workers and machinery to create a secure work environment, simultaneous worker location recognition, detection of individuals working alone, and monitoring of safety gear usage.

- - Replacing Visual Inspections: Automated and quantifiable monitoring of production quality, detection of wiring mistakes, contamination, and verification of packaging standards.

- - Enhancing Factory Productivity: Monitoring factory conditions to identify inefficiencies, visualize line operating rates, and detect anomalies in outdated equipment.

Moreover, the data processed and stored by this hardware will eventually support further analysis and decision-making through enhanced integration with Schneider Electric's group company, AVEVA’s cloud solution, CONNECT.

As manufacturing faces challenges such as a declining workforce and technology transfer issues, the adoption of AI technology is seeing mounting interest. Schneider Electric aims to leverage its collaboration with Sony, pooling their product offerings and technologies to promote broad-scale AI utilization in manufacturing, thereby accelerating a pioneering blend of cutting-edge technology.

About Schneider Electric

Schneider Electric is a global leader in energy management and automation, committed to enabling everyone to make the most of their energy and resources while driving progress and sustainability. The company's purpose is encapsulated in the phrase, 'Life Is On.'

We strive to be the trusted partner in sustainability and efficiency, offering top-tier expertise in electrification, automation, and digitalization across diverse sectors including advanced manufacturing, resilient infrastructures, intelligent buildings, and intuitive home automation. By providing integrated, AI-ready industrial IoT solutions through connected products, automation, software, and services, we support our customers’ success and growth in all phases of the lifecycle, aided by digital twin realization.

With a workforce of 168,000 employees and a network of over 1 million partners, we are a people-centered business operating in more than 100 countries, dedicated to fostering close relationships with customers and stakeholders. Under our significant purpose of creating a sustainable future for all, we prioritize diversity and inclusion in all activities.

Explore More

Conclusion

The introduction of this AI-powered safety solution from Schneider Electric and Sony Semiconductor Solutions not only represents a significant step forward in manufacturing safety measures but also underlines the growing importance of AI technology in industrial applications. As these companies continue to innovate and expand this solution's capabilities, the prospects for safer, more efficient manufacturing environments appear brighter than ever.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.