Revolutionizing Electric Motors: New Iron Nitride Magnets Without Rare Earths

Introduction

In a groundbreaking development, three major Japanese companies, Sankei Giken Co., Mitsuba Corporation, and Future Materialz, have successfully created iron nitride magnets, demonstrating their effectiveness in automotive electric motors.

These magnets stand out by utilizing no rare earth elements and making good use of samarium, a byproduct from neodymium extraction. While maintaining the performance level of conventional neodymium magnets, they promise a continuous production cycle and contribute to reducing resource risks, advancing towards sustainable supply chains. This innovation has been formally announced at several key conferences, including The 70th Annual Conference on Magnetism and Magnetic Materials and the 35th FINETECH JAPAN.

Background

As the demand for efficient electric motors grows, there is a pressing need for powerful permanent magnets that can enhance motor performance while minimizing size. Neodymium magnets, widely used in energy-saving appliances and electric vehicles, are notorious for their heavy reliance on rare earth elements, which often leads to supply chain vulnerabilities. The future of compact and efficient motors depends on technological advancements that either limit the use of these elements or replace neodymium magnets entirely with new materials that exhibit strong magnetic properties.

Iron Nitride Magnets Explained

Iron nitride magnets are composites made primarily of iron nitride (Fe16N2) and samarium iron nitride (Sm2Fe17N3). The concept of iron nitride was initially introduced by Professor Minoru Takahashi in 1972 at Tohoku University, and recent advancements have made it possible to produce a large quantity of high-purity iron nitride powder. This advancement fuels ongoing development in magnetization research. In contrast, samarium iron nitride is seen as a promising alternative to neodymium magnets, especially in replacing heavy rare earth elements. Notably, the new iron nitride magnets drastically reduce the reliance on rare earth elements by substituting samarium iron nitride with iron nitride. Their manufacturing flexibility allows for tailored magnetic properties to suit various applications.

Key Features and Achievements

1. Manufacturing Versatility: These iron nitride magnets can be produced through both powder compaction and injection molding techniques, showcasing their adaptability.

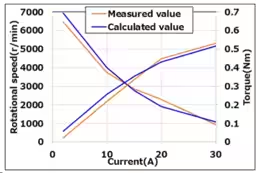

2. Optimized for Automotive Use: The team has developed magnets specifically designed for electric motors used in vehicles, achieving nearly identical theoretical and measured magnetic properties during testing.

3. Resource Resilience: The structure of the new magnets primarily consists of iron and nitrogen, presenting advantages over neodymium magnets in terms of price stability and reduced supply risks. Traditional neodymium magnets often necessitate the addition of heavy rare earth elements, such as terbium and dysprosium, to enhance magnetic performance. However, the significant dependency on specific supplier nations can inflate costs and exacerbate supply concerns. The new iron nitride magnets avoid using such rare earth components.

Future Directions

Looking ahead, Sankei Giken, Mitsuba, and Future Materialz are committed to collaborative research focused on enhancing the properties of magnetic powders and magnets. They are also keen on exploring various applications of these iron nitride magnets in different types of automotive electric motors, underscoring a strong commitment to innovation and sustainability in technology.

Visual Representations

Refer to the following figures for illustrations of the iron nitride magnets:

- - Figure 1: Sample iron nitride magnet pellets produced via injection molding and pressed magnets.

- - Figure 2: Performance characteristics of the motors using the new magnets, showcasing the relationship between current, rotation speed, and torque, comparing measured data to calculated values.

- - Figure 3: An automotive application of the created magnets in wiper motor technology.

This technological leap not only provides high-performance alternatives to existing solutions but also promotes a greener, more sustainable future in the automotive sector. As the world moves toward electric mobility, there is a prominent ethical and practical imperative to evolve from rare earth dependency to innovative, homegrown solutions like iron nitride magnets.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.