NABLAS and Somic's Collaboration Revolutionizes AI for Small-Medium Manufacturing

Transforming Manufacturing with AI

In a groundbreaking partnership, NABLAS Inc., an AI comprehensive research institute based in Bunkyo-ku, Tokyo, collaborates with Somic Transformation, located in Hamamatsu, Shizuoka, to develop an innovative AI-based visual inspection system. This endeavor addresses longstanding challenges faced by small-to-medium-sized manufacturing operations, particularly in their quality assurance processes.

The Context of the Project

Every year, Somic Ishikawa, a subsidiary of Somic Transformation, manufactures a staggering 400 million critical safety components known as ball joints. With a mission centered on "Connecting Smiles to the Next Generation," their focus on relieving the burden of human work in the inspection process has been transformative. The inspection procedure, a vital aspect of any manufacturing operation, often requires high precision and sustained concentration, creating substantial pressure on inspectors. This project aims to leverage AI technology to alleviate such pressures while simultaneously addressing the broader labor shortage and high costs that hinder the widespread adoption of AI in the industry.

Addressing Key Challenges

Together, NABLAS and Somic Transformation undertook the challenge to resolve four significant issues prevalent in manufacturing:

1. The Burden of Inspection Processes: The traditional method of human visual inspection has become an arduous task, requiring extreme focus and accuracy over extended periods. The physical and mental strain on inspectors is considerable.

2. Quantifying Expertise: The high-quality standards for parts, like ball joints, have been upheld by skilled inspectors. Acknowledging this expertise, the project seeks to quantify their knowledge and experience to create an extensive and high-quality data set, forming the foundation for AI development.

3. High Implementation Costs: The prohibitive costs associated with integrating AI into manufacturing processes pose a barrier, especially for small and medium enterprises. Somic Transformation has prioritized creating a cost-effective solution that is accessible to all.

4. Complexity of AI Integration: Introducing AI inspection technologies for intricate components like ball joints has proven to be a formidable challenge due to their complex geometries and demanding quality requirements.

NABLAS's Development Approach

NABLAS took a collaborative approach to tackle these issues by immersing itself in the real-world challenges of the manufacturing setting. Through iterative experimentation, the team focused on achieving tangible solutions.

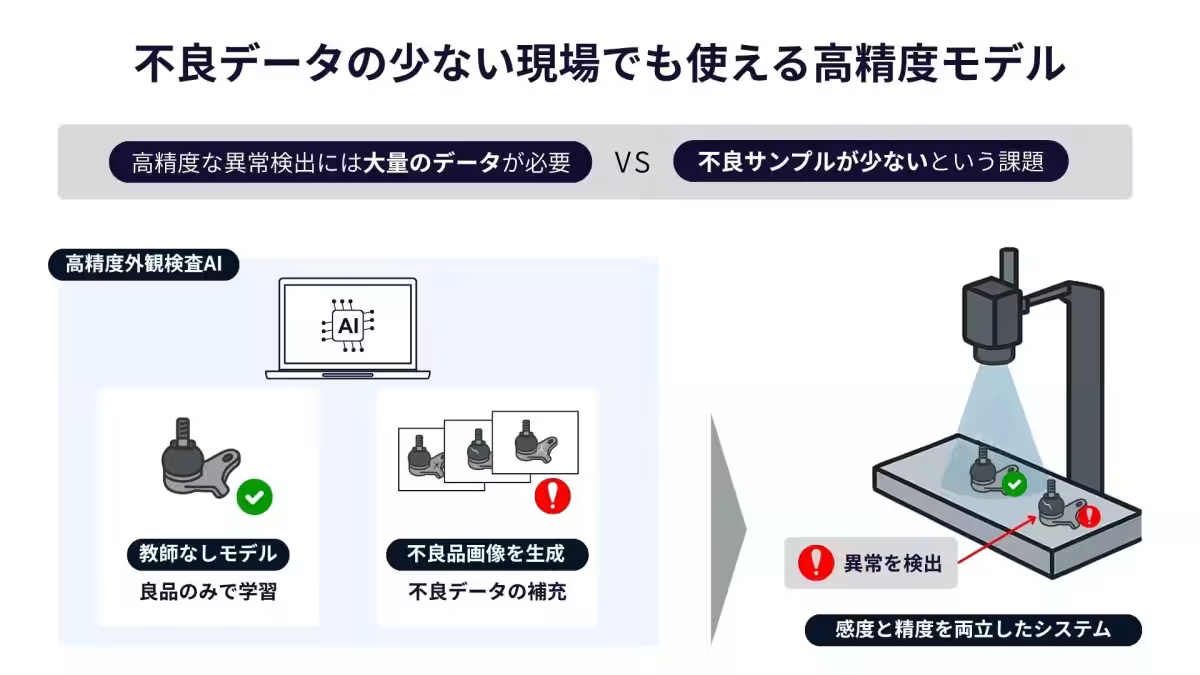

Development of a High-Precision Model

One critical area was the development of a high-precision model aimed at minimizing false detections and missed anomalies. Given the rare occurrence of defective items, enhancing precision presents its hurdles. To address this, the project utilized unsupervised models trained solely on quality control data, alongside sophisticated techniques to generate high-quality defect images. This innovative approach led to a functional AI visual inspection system that balances sensitivity and accuracy.

Multi-Angle Image Analysis

To ensure precise detection, multiple images of ball joints were captured from various perspectives and categorized by specific components. This multi-angle approach allows for a comprehensive understanding of the complex shapes involved, enabling accurate anomaly detection.

System Optimization for Real-world Application

Understanding the need for practical implementation, NABLAS standardized the system's data and output specifications according to Somic Ishikawa's operational environment. Efforts were also made to streamline the AI model's processing speed, facilitating real-time anomaly detection directly on the manufacturing line. This optimization resulted in a smooth implementation process, providing a practical solution to previous challenges.

Article Release

The details of this groundbreaking project, including the voices from the field and the journey to implementation, have been compiled into an article now available on the Somic Group's brand website. This serves as a valuable case study for manufacturing professionals considering AI integration.

Future Outlook

Looking ahead, NABLAS is committed to continuous AI development and integration that aligns with the real challenges of manufacturing environments. Beyond inspection, their support may extend to maintenance, process management, and demand forecasting, broadening the scope of AI solutions available in the industry.

Contact Information

For inquiries related to the implementation of AI solutions in manufacturing, please feel free to reach out using the contact form provided.

About NABLAS Inc.

Founded in March 2017, NABLAS Inc. is a venture originating from the University of Tokyo. The organization focuses on training AI personnel, consulting, and providing solutions leveraging advanced AI and Deep Learning technologies. Constantly seeking to implement AI in various sectors, they operate under the mission "Discover the gradients, Towards the future," aiming to innovate technologies and services that will shape a better tomorrow.

Company Information:

- - Name: NABLAS Inc.

- - CEO: Kohtaro Nakayama

- - Headquarters: Bunkyo-ku, Tokyo, 1F Hongo Tsuna Building, 6-17-9

- - URL: https://nablas.com

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.