Over Half of Participants Report Issues in Custom Goods Production Survey

Exploring the Reality Behind Issues in Custom Goods Production

A recent investigation by Plus One International, a company based in Takamatsu, Kagawa founded by CEO Tsuyoshi Shinkai, sheds light on the various troubles faced during the production of original merchandise. The survey aimed to understand the occurrences of issues related to custom goods production and the criteria individuals prioritize when selecting a production company.

Survey Overview

- - Survey Period: September 17-19, 2025

- - Method: Internet survey conducted by PRIZMA

- - Participants: 1,007 individuals who have experience in creating custom goods

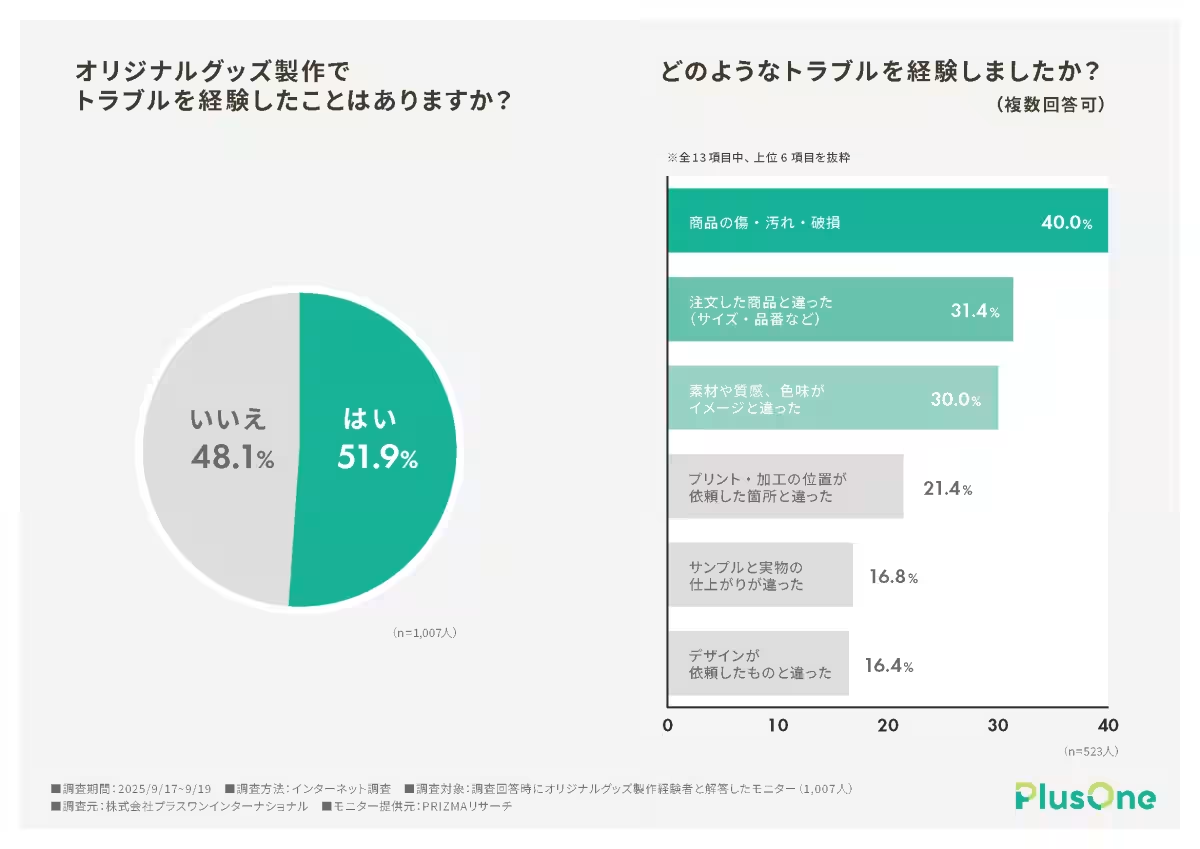

According to the findings, an alarming 51.9% of respondents indicated that they had faced problems in the production of original merchandise, ranging from team apparel to event goods and promotional items.

Common Problems Encountered

When asked about the types of troubles encountered, participants reported several recurring issues:

- - Product defects such as damage or dirt (40%)

- - Incorrect items received (31.4%)

- - Discrepancies in material, textures, or colors (30%)

Such findings highlight the frequent production discrepancies that arise, emphasizing they often stem from human errors or failures in quality control. Furthermore, the gap between expected and delivered product conditions seemed to be prevalent among user experiences.

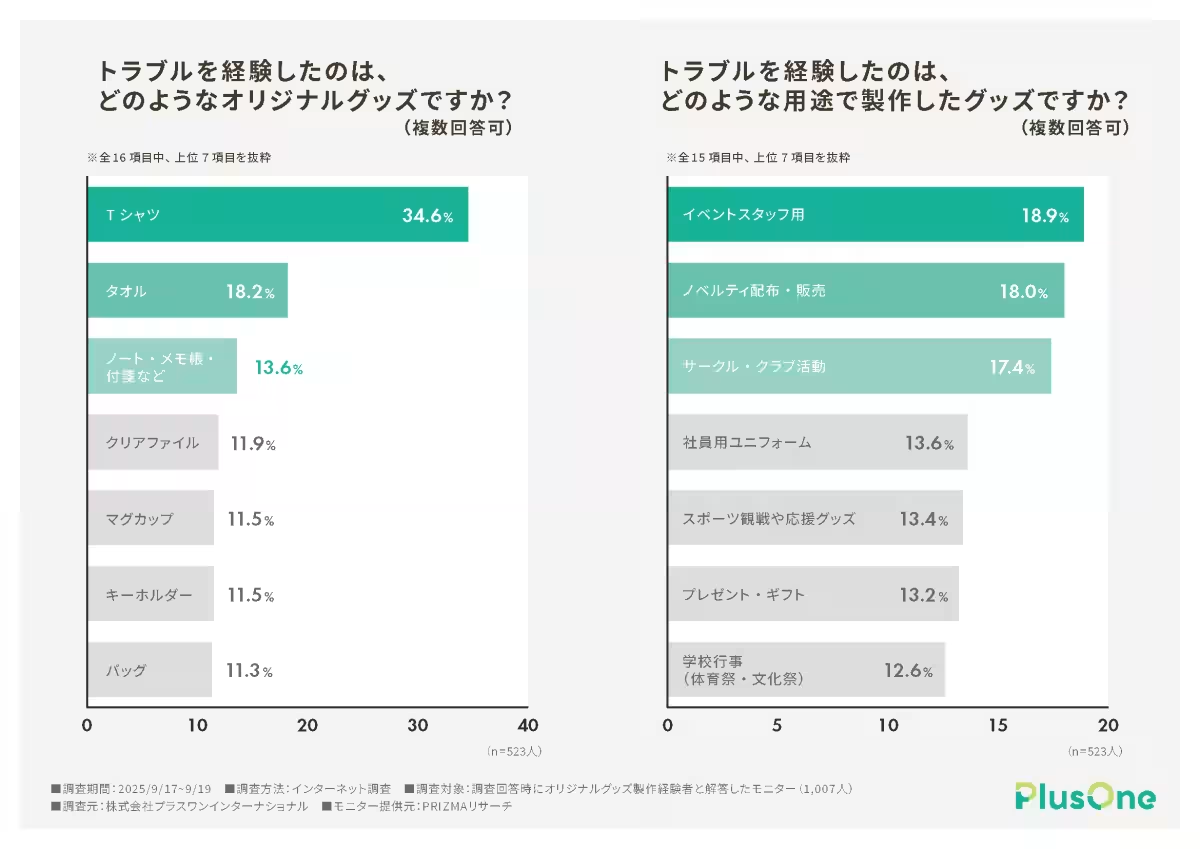

T-Shirts at the Top of the Trouble Chart

In terms of specific merchandise that experienced the most issues, T-shirts emerged as the primary offender, with 34.6% of respondents indicating trouble associated with them. Other items included towels (18.2%) and stationery products like notebooks (13.6%), commonly used in various events or as promotional giveaways.

The survey also explored the intended purposes of these goods, revealing that most troubles occurred for:

- - Event staff use (18.9%)

- - Promotional purposes (18.0%)

- - Club or circle activities (17.4%)

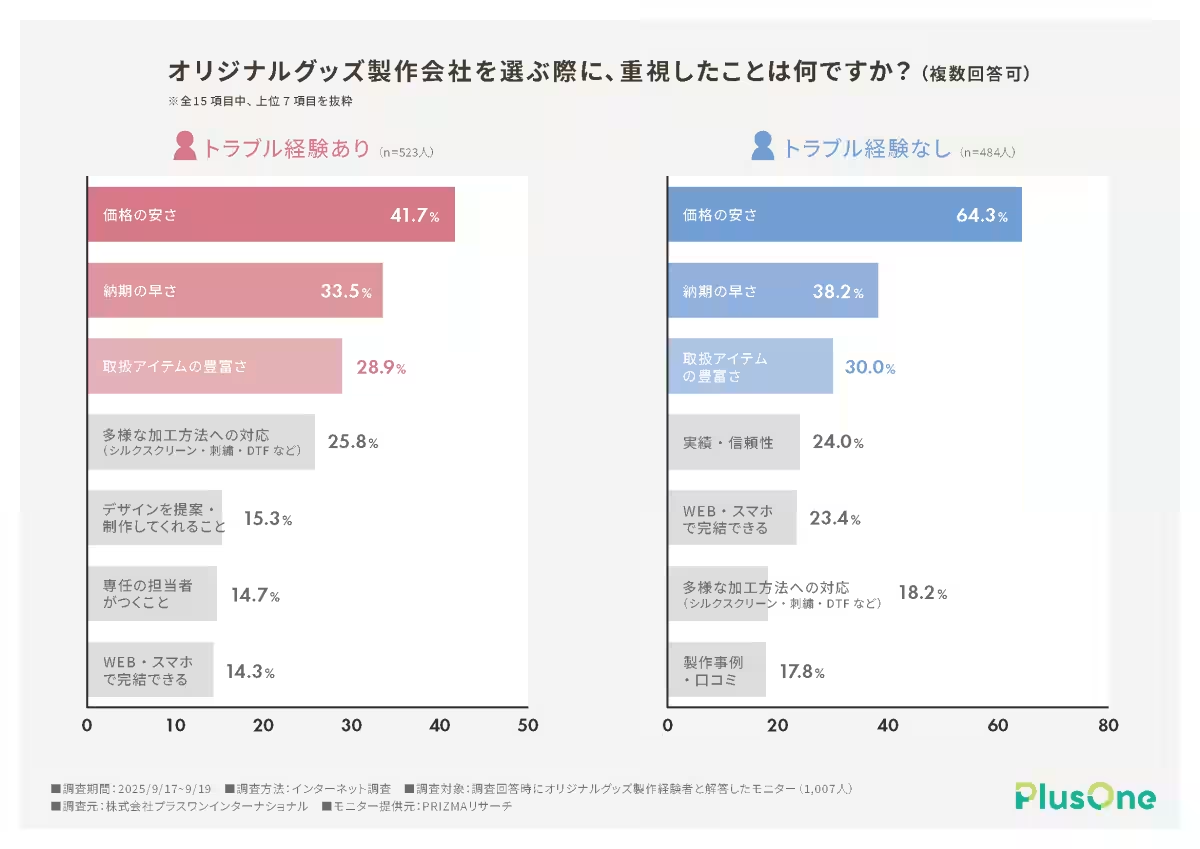

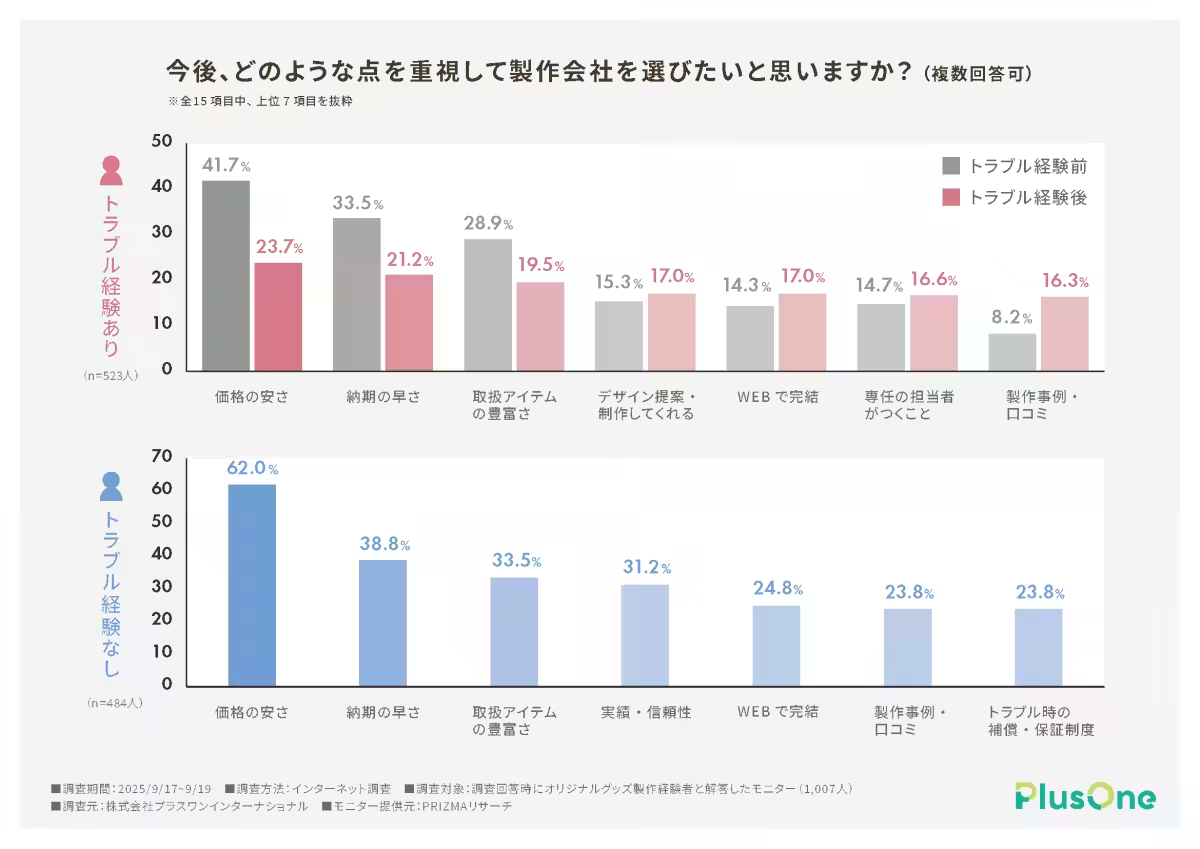

Choosing Production Companies: Cost is King

When queried about their selection criteria for custom goods manufacturers, participants overwhelmingly prioritized cost, followed by speed of delivery and diversity of product offerings. Interestingly, those who hadn’t experienced troubles tended to consider company reliability and testimonials more heavily, hinting at a quest for information to avoid potential issues.

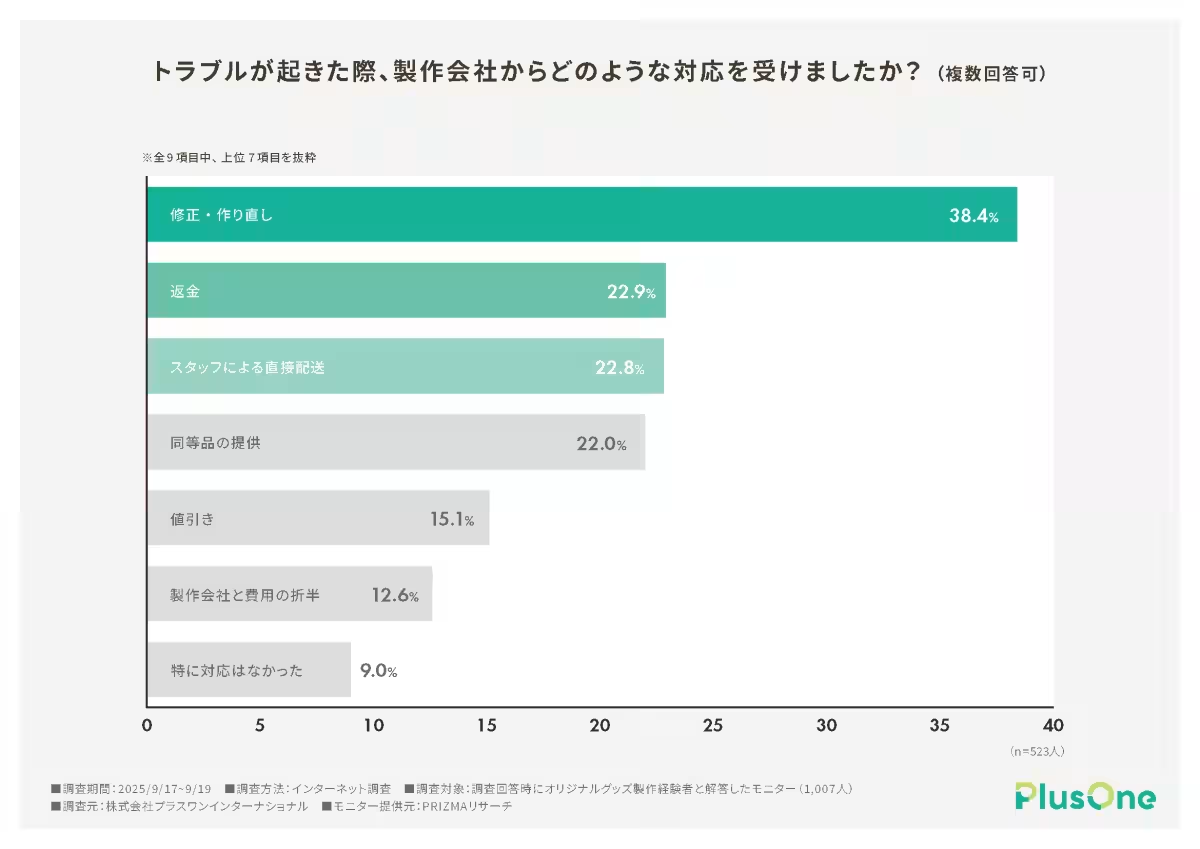

Company Responses to Problems

Participants who faced difficulties were asked how the production companies responded. Most reported receiving corrective actions such as:

- - Refinements or reprints (38.4%)

- - Refunds (22.9%)

- - Direct delivery by staff (22.8%)

Due to the time-sensitive nature of many custom goods, such as those used in events, rapid responses and exchanges were not uncommon based on the problem encountered.

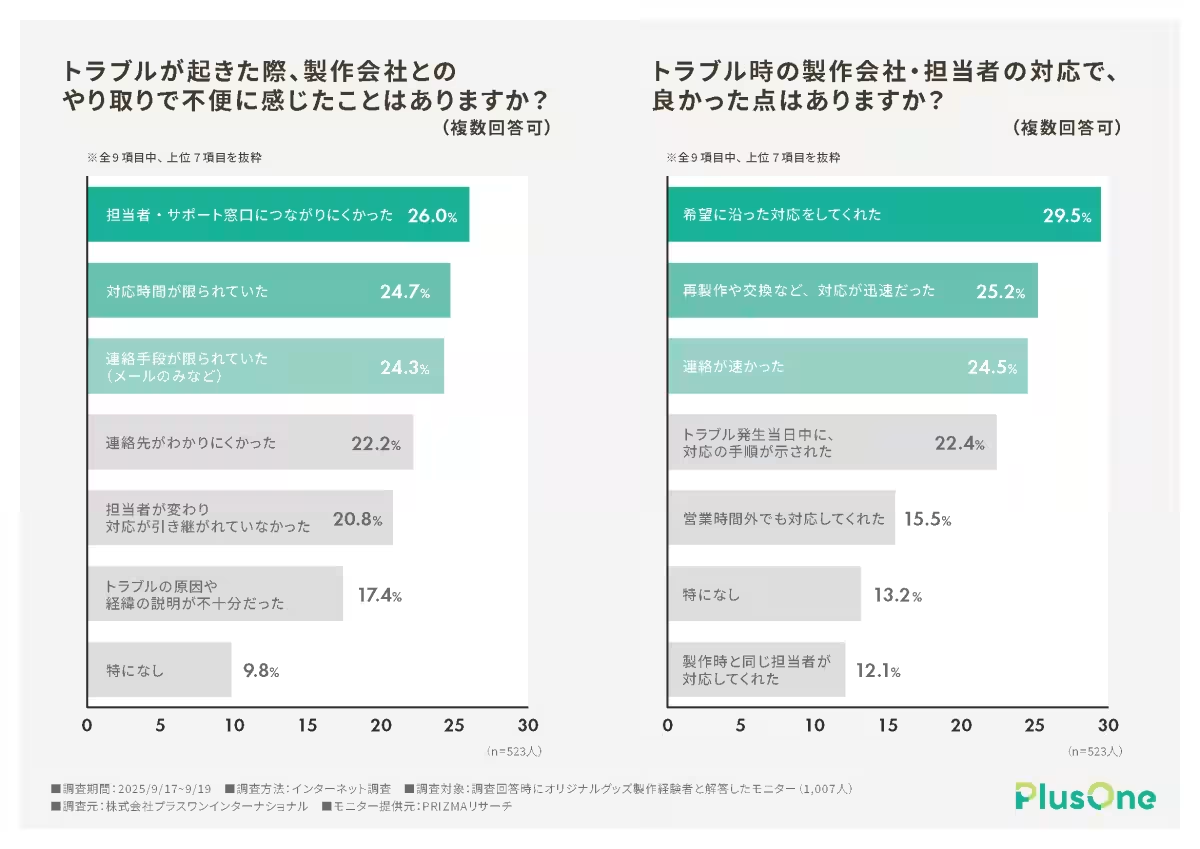

Communication Challenges in Trouble Situations

Despite some positive reactions to company responses, many participants still expressed concerns about communication hurdles. Notably, 26% found it challenging to connect with support personnel, and many stated that the limited communication methods—such as being restricted to email—added to their frustrations.

In contrast, notable positives from participant feedback included prompt support aligned with their requests and the swiftness of the company's responses.

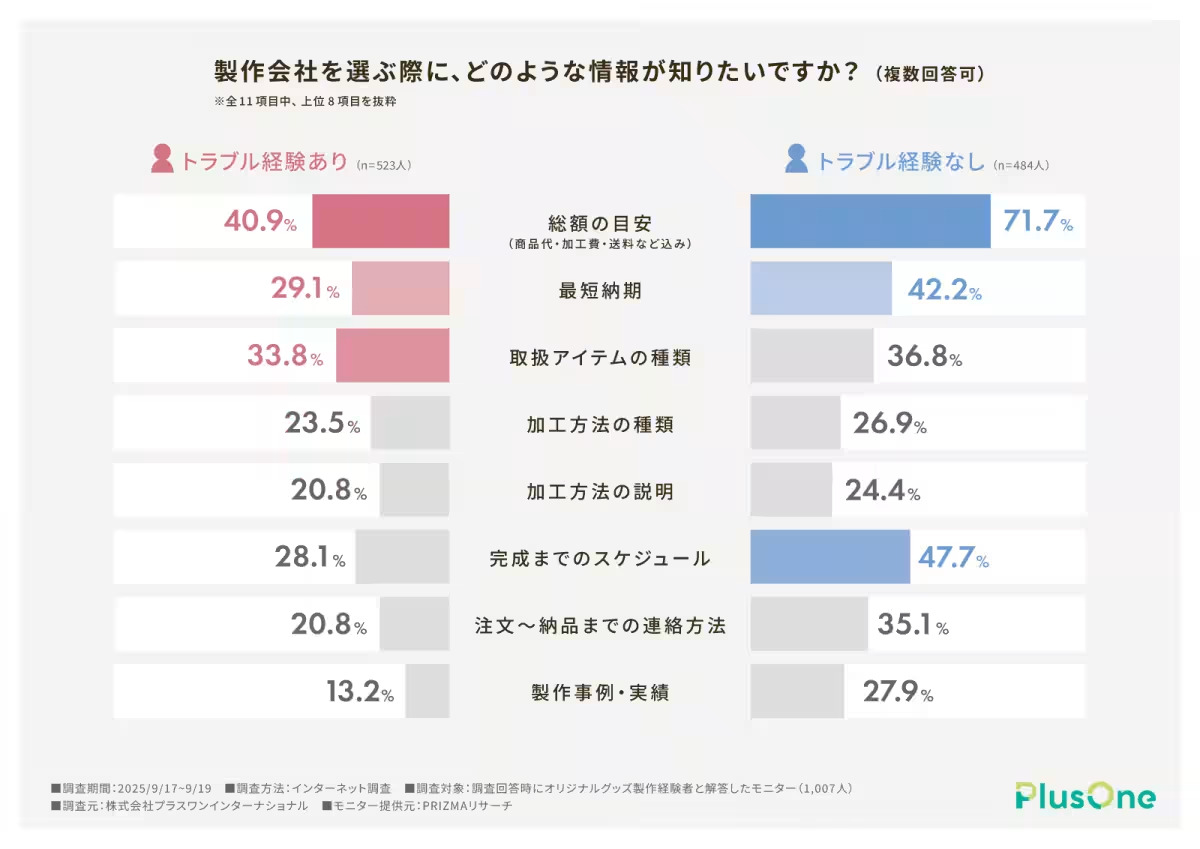

Key Information Desired in Company Selection

Respondents were asked what information they consider essential when choosing a manufacturing company:

- - Overall cost estimates topped the list, showcasing a fundamental need to grasp the financial aspect ahead of any commitments.

- - Many also expressed interest in knowing the fastest production timelines, suggesting that comprehensive knowledge about the manufacturing process might prevent future errors.

Changes in Selection Priorities Post-Experience

Finally, when respondents were asked how their priorities changed after experiencing troubles, it was noted that while cost and delivery speed remained crucial, interest in support systems and customer testimonies increased significantly. The need for a dedicated contact person and design support also gained traction among those who had faced issues previously, reflecting a desire for guidance throughout the production process.

Conclusion: An Eye on Quality and Support

The findings of this survey reveal a concerning trend: a significant majority of individuals involved in custom goods production have faced problems. The nature of these issues often relates to product quality or fulfillment errors. T-shirts stand out as the most problematic item, particularly for event-related uses where timely delivery is crucial.

How companies respond to these challenges, combined with the importance of effective communication, highlights areas needing improvement. With fluctuating focus in company selection criteria, it appears quality assurance, support, and transparent communication are foundational aspects that influence customer experiences in the realm of custom goods production.

About Plus One International

Plus One International is dedicated to bringing the joy of creativity to the forefront, providing quick and reliable custom merchandise solutions. With services like same-day printing and engaging workshops available across Japan, they are committed to enhancing every customer’s creative journey.

Company Overview

- - Company Name: Plus One International

- - Headquarters: 5116-20, Kitacho, Takamatsu, Kagawa

- - Established: October 1999

- - Founder: Tsuyoshi Shinkai

- - Website: Plus One International

- - Business: Manufacturing and selling apparel and paper products

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.