Zeon Corporation Launches IoT Common Platform to Optimize Manufacturing Operations

Zeon Corporation's New IoT Common Platform for Manufacturing

Zeon Corporation, based in Chiyoda, Tokyo, has recently initiated operations for its newly established IoT common platform. This strategic move aims to bolster the company's efforts towards becoming a smart factory across all operations. By implementing this platform, Zeon seeks to better visualize and utilize diverse data collected from its manufacturing facilities and research sites, significantly improving operational efficiency and advancing its digital technology initiatives.

The Pursuit of Smart Manufacturing

Since 2020, Zeon has focused on incorporating digital technologies to enhance production optimization while ensuring product quality. The company acknowledges that ensuring stable operations is paramount. As such, their manufacturing systems (including plant control systems and various monitoring technologies) are functionally isolated from other internal networks. This separation enhances security by preventing unauthorized external access. However, this operational model complicates data utilization across the company, presenting a challenge in their journey toward smart manufacturing.

To overcome these hurdles, Zeon embarked on constructing an IoT common platform that facilitates safe, company-wide access to accumulated operational data. They have streamlined their system to effectively implement ideas generated at each site quickly.

Key Features of the IoT Common Platform

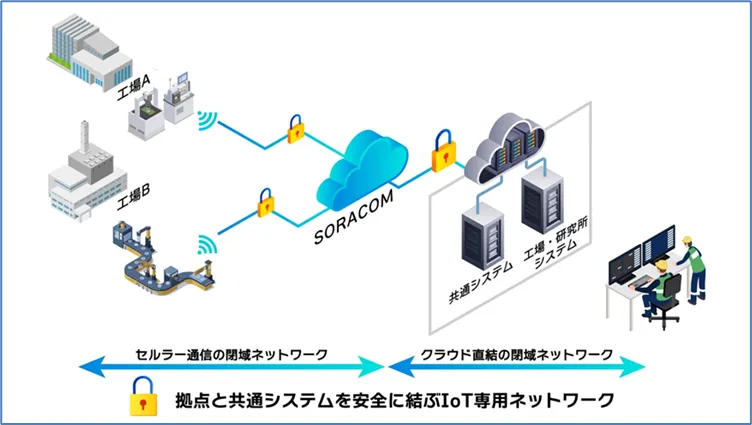

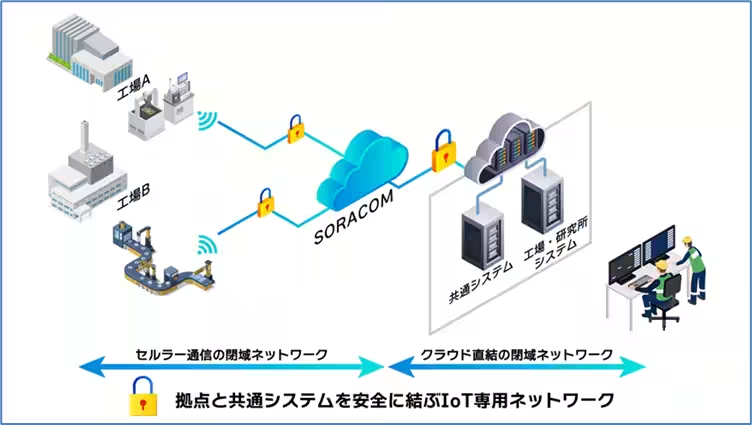

One of the most notable features of this new initiative is the integration of independent measuring devices connected via a closed cellular communication network to a centralized cloud system. This advanced approach ensures high security while allowing for a flexible and rapid implementation of the IoT system. With this closed cellular network, extensive installation work for wired LANs is no longer necessary, simplifying the connection of sensors and analytical devices. Consequently, this setup has enabled site-driven installations and accelerated deployment processes.

The gateway installation is straightforward; placing it in any desired location creates a network that is accessible internally while being secure from external access.

During the development of the IoT platform, Zeon collaborated with Soracom Corporation, an IoT platform provider, leveraging their communication and cloud technology expertise, as well as specialized consulting services for system design.

Pilot Projects and Future Implementation

Prior to the rollout of the common platform, Zeon developed a 'Equipment Operational Monitoring System' at the Takaoka Plant, which began its operational phase after passing the Proof of Concept (PoC) stage in May 2025. This initiative has significantly reduced the need for routine inspections previously done within the factory premises, alleviating operational burdens. Furthermore, the capture of real-time data has allowed for early detection of anomalies and predictive analysis.

Currently, multiple sites are progressing with PoCs for IoT projects utilizing this common platform, and those initiatives that have yielded high effectiveness will be gradually expanded across Zeon's nationwide manufacturing sites. This transition promises increased productivity, more effective operational management, and greater data management capabilities, all while upholding security protocols.

Commitment to Sustainable Manufacturing

In the future, Zeon aims to further integrate advanced technologies such as remote monitoring, data analysis, and artificial intelligence (AI) into their operations. This continued evolution represents their commitment not only to improving production systems but also to achieving sustainable manufacturing practices.

Conclusion

Through the establishment of its IoT common platform, Zeon Corporation is not just enhancing its operational capabilities but is also setting a benchmark for smart manufacturing in the industry. Their strategic investments in technology highlight their proactive approach to navigating the complex modern manufacturing landscape, guaranteeing better efficiency and sustainability for years to come.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.