JBMIA Develops Recycled Plastics for OA Equipment and Consumer Products

Overview of JBMIA's Recycled Plastic Initiative

The Japan Business Machine and Information System Industries Association (JBMIA), based in Minato, Tokyo, has made significant strides in the development of recycled plastics tailored specifically for use in office automation (OA) devices like printers and copiers. This year, the organization will begin examining the implementation of their newly developed polystyrene (PS) recycled plastics across various products.

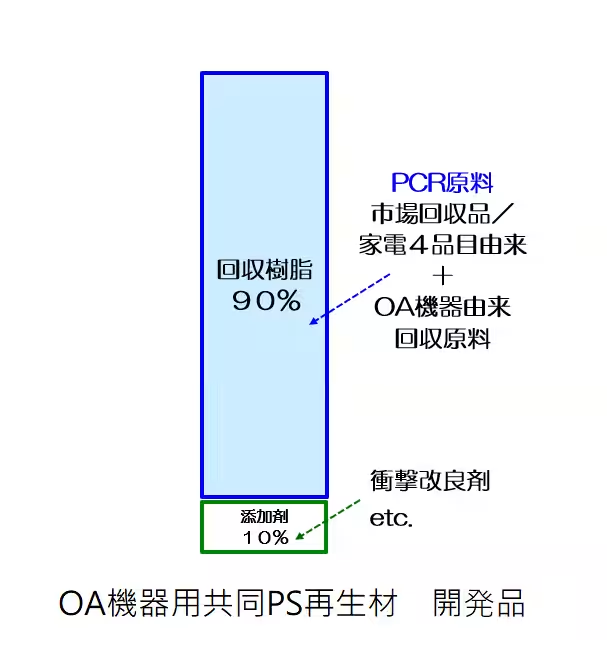

This innovative recycled plastic is comprised of 90% hybrid PCR (Post-Consumer Recycled) materials, sourced from plastics collected from OA equipment and home appliances. Moreover, the material has met safety standards under UL94, ensuring that it is safe for usage in consumer products.

1. Outline of the JBMIA Recycled Plastic Circular System

1.1 Responsibilities of Collaborating Parties

JBMIA and participating resin compound manufacturers have divided their responsibilities effectively:

JBMIA Members:

- - Conduct specifications that are universally applicable across copiers and printers.

- - Design usage and evaluate performances.

- - Establish quality assurance for recycled materials collected from workplaces.

- - Build a comprehensive circular scheme for JBMIA recycled plastics.

Resin Compound Manufacturers:

- - Develop compact recipes for recycled plastics that utilize thin materials and high rates of PCR content.

- - Innovate methods for assessing the quality of recycled plastics.

- - Ensure quality assurance for materials sourced from home appliances.

- - Acquire safety compliance regarding recycled plastic.

1.2 Development Journey

The Plastic Material Recycling Task Force was established in 2020, aiming to tackle two essential goals:

- - To contribute to global efforts addressing the stringent regulations on plastic resource circulation by collaboratively working on solutions within the industry.

- - To support the member companies’ businesses through this initiative.

From the subsequent year onward, activities were carried out under the banner of the Plastic Material Recycling Committee, leading to significant advancements in both open and closed material recycling applications. Although initial challenges including unified material grades and balancing supply and demand rendered development seemingly impossible, the merger of recycled plastics from OA devices and those from different industries facilitated achievable solutions, thus propelling the project forward.

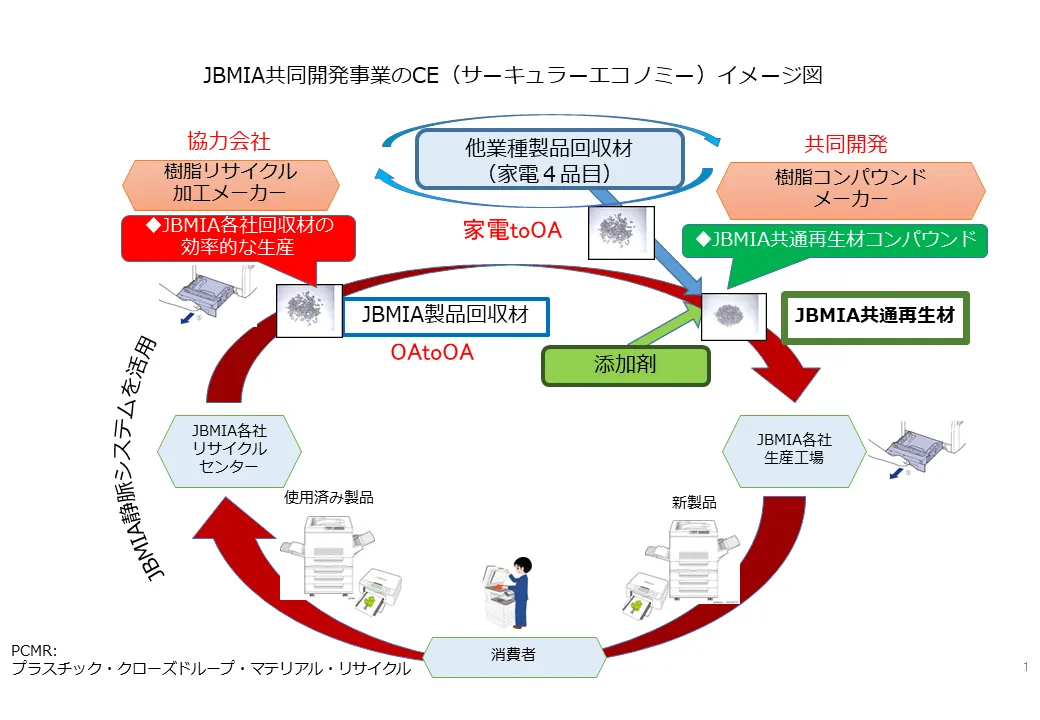

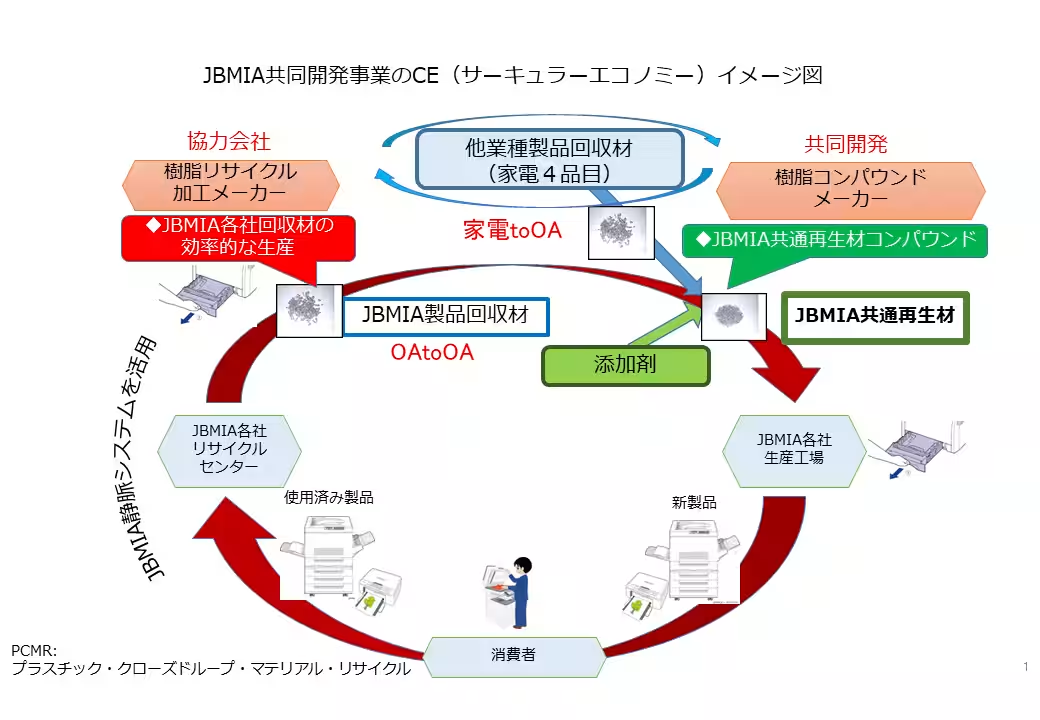

2. Overview of JBMIA PS Recycled Plastic CE (Circular Economy)

Historically, Plastic Closed-Loop Material Recycling (PCMR) was executed independently by firms, without a unified industry approach. The current efforts towards developing a common recycled plastic from PCR materials — targeting both OA-to-OA and home appliance-to-OA recycling — will enhance the implementation of Principles of Circular Economy within the OA and IT device sectors.

3. Remaining Challenges and Future Directions

While a determination has been achieved regarding mass production viability in terms of quality and supply, corporations still face the challenges of economic feasibility (cost) and product quality assessments before widespread adoption can take place. Careful consideration of compliance with regulations will also be prioritized in future discussions.

4. Future Developments

4.1 Expansion of Recycled Plastic Material Targets

Currently focused on PS plastics, JBMIA has plans to broaden its scope to include other plastic materials.

4.2 Key Focus Themes

Three primary themes for JBMIA’s future initiatives have been established:

- - Promoting sustainable infrastructure development while enhancing industrial competitiveness through innovation.

- - Advancing efforts to create safe and secure office environments that are responsive to global changes.

Through this initiative led by the Plastic Material Recycling Task Force, JBMIA commits to further promoting the construction of a sustainable societal framework. By aligning this initiative with SDG Goal 12, which emphasizes responsible consumption and production, the organization aims to play a pivotal role in realizing a Circular Economy.

Topics Environment)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.