Reducing Inventory Management Time with SmartMat Cloud: A Success Story

Success Story of SmartMat Cloud in Inventory Management

In an era where efficiency is paramount, the integration of advanced technology into business processes can greatly alter productivity levels. SmartMat Cloud, an Internet of Things (IoT) inventory management system operated by Esmat Co., Ltd., in collaboration with Canon Marketing Japan Inc., recently showcased a successful case study with Sekisui Seikei Co., Ltd.’s Kanto factory. This partnership has led to a remarkable reduction of 80 hours per month in inventory-related operations, significantly relieving strain on the workforce while mitigating stock-out risks.

Background of the Case Study

Sekisui Seikei Co., Ltd. specializes in manufacturing plastic products, including those for tatami-related materials, packaging, general merchandise, and industrial supplies. Their Kanto factory operates 24 hours a day under a four-group, three-shift system, focusing on producing liquid transport containers for industries such as food, pharmaceuticals, and electronics. Given the critical nature of their output, effective inventory management is essential.

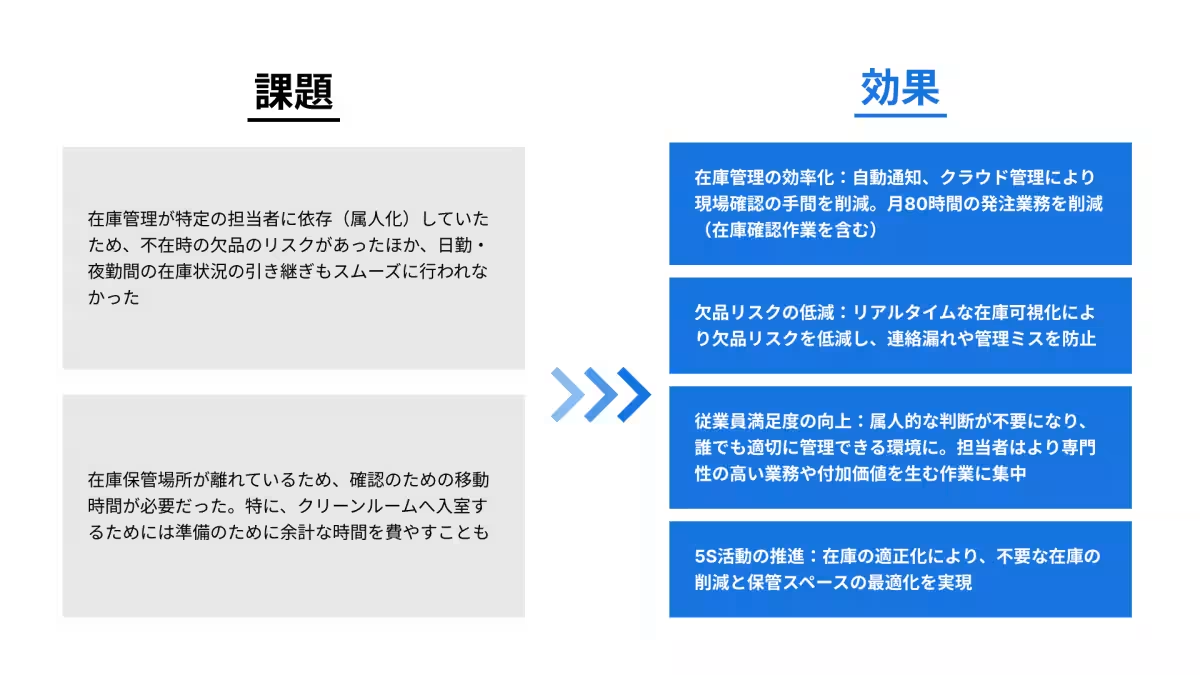

Previously, the factory faced significant challenges due to an over-reliance on specific employees for inventory management, creating risks for stock outages when key personnel were unavailable. Moreover, the separation of inventory storage from the operational office necessitated considerable travel time for staff checking stock levels, particularly in sensitive areas like clean rooms, where strict hygiene protocols further complicated processes. These inefficiencies sparked the consideration for a technological intervention.

Challenges and Implementation Effects

To address these deficiencies, Sekisui Seikei turned to SmartMat Cloud. This powerful SaaS solution automates inventory visibility by utilizing IoT technology to continuously track stock levels in real-time. By shifting away from manual stocktaking, the factory could eliminate the extensive man-hours previously required for inventory management. The system not only enables rapid inventory checks but also automatically adjusts orders based on real-time data, greatly enhancing operational efficiency.

Through the implementation of SmartMat Cloud, Sekisui Seikei reported significant improvements in inter-shift communications and coordination, eliminating delays and ensuring that all shifts are aligned on inventory statuses. The net result is a streamlined operation that mitigates the risk of production pauses caused by supply shortages, enhancing the overall productivity of the Kanto factory.

Overview of SmartMat Cloud

SmartMat Cloud revolutionizes inventory management by visualizing the actual stock levels of all items through an IoT framework. The solution promotes a smooth path towards automation and process improvement by simplifying complex inventory tasks. With applications spanning various industries—including manufacturing, service, and even healthcare—SmartMat Cloud has seen adoption from over 1,200 customers since its inception in late 2018. The platform’s ability to facilitate accurate, real-time inventory management and automate ordering processes illustrates its potential for significant efficiency gains across diverse sectors.

About Esmat Co., Ltd.

Formerly known as Smart Shopping, Esmat Co., Ltd. aims to supercharge the flow of goods with a smart approach to inventory management. Their flagship product, SmartMat Cloud, is designed to help B2B clients—particularly in manufacturing and healthcare—automate their inventory management and ordering processes. Founded in November 2014 and headquartered in Shinagawa, Tokyo, Esmat continues to innovate and adapt to the needs of the modern marketplace.

For further details on this case study, check out the complete article here.

Full details about SmartMat Cloud can be found on its official website: SmartMat.

Through innovative solutions like SmartMat Cloud, companies can achieve unprecedented levels of operational efficiency and accuracy, ensuring that they remain competitive and responsive to market demands.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.