Mitsubishi Shipbuilding Achieves Basic Design Approval for Onboard CO2 Capture System

Mitsubishi Shipbuilding's Groundbreaking CO2 Capture System

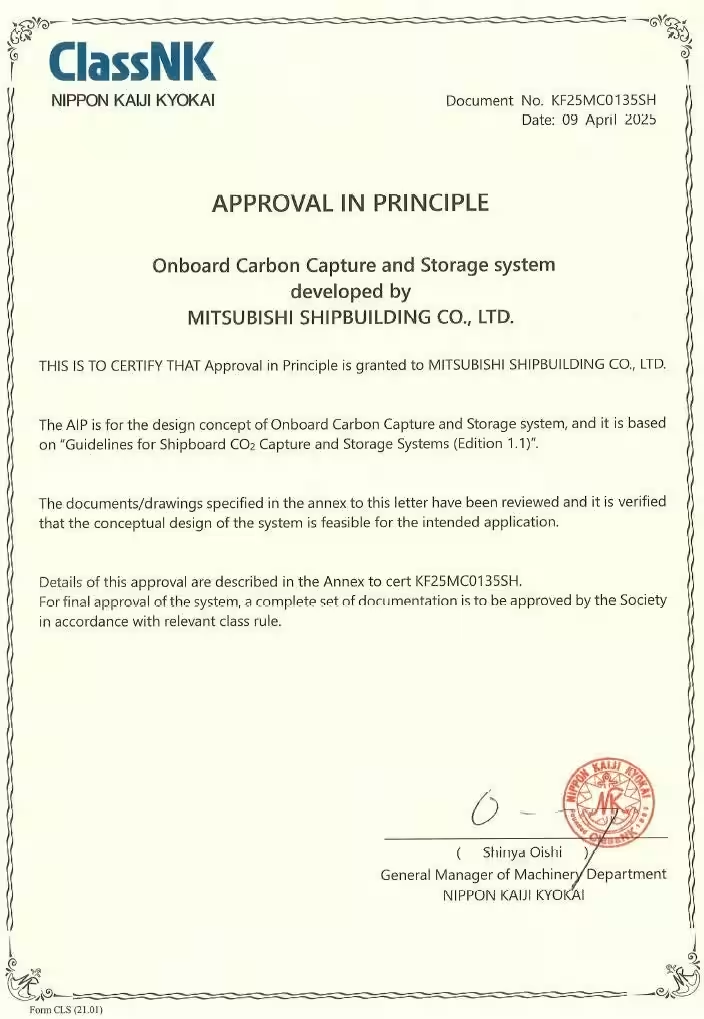

Mitsubishi Shipbuilding Co., Ltd., part of the Mitsubishi Heavy Industries Group, recently achieved an important milestone by obtaining Approval in Principle (AiP) for its onboard carbon capture and storage system (OCCS) from the Nippon Kaiji Kyokai (NK). This initiative is significant as it aligns with global efforts to decarbonize the maritime industry, which is facing increasing pressure to reduce greenhouse gas emissions.

Understanding the Onboard CO2 Capture System (OCCS)

The OCCS developed by Mitsubishi Shipbuilding is designed to capture carbon dioxide emitted from vessels during their operation. By first purifying exhaust gases, the system subsequently liquefies and stores CO2 onboard. This technology is seen as one of the key solutions to decreasing maritime emissions, showcasing Mitsubishi's commitment to combat climate change within the shipping industry.

Mitsubishi Heavy Industries' expertise in CO2 capture technology on land, such as the KM CDR Process™, plays a central role in the OCCS development. The system integrates various technologies including exhaust gas preprocessing, liquefaction, storage, and handling, creating an efficient framework that can be utilized on vessels. With this AiP in hand, Mitsubishi Shipbuilding plans to expedite the commercialization of the OCCS, which is critical given the global urgency surrounding decarbonization efforts.

The Energy Transition Strategy

As part of its broader strategy for energy transition, the Mitsubishi Heavy Industries Group is committed to strengthening its businesses that address sustainable energy solutions. Mitsubishi Shipbuilding aims to contribute to the development of the maritime industry not only through traditional shipbuilding but also through maritime engineering technology rooted in shipbuilding. The OCCS is a pivotal project within this strategy, reflecting Mitsubishi's proactive stance on environmental responsibility.

With the intensifying need for initiatives to reduce greenhouse gas emissions globally, Mitsubishi intends to continue its efforts in developing strategies to tackle emissions from vessels. This project represents a significant step towards the decarbonization of the maritime sector, helping to ensure a more sustainable future for shipping.

Approval in Principle and Regulatory Compliance

The Approval in Principle (AiP) designation is granted by certification bodies when a proposed design meets defined technical and safety standards. In this case, the evaluation was conducted based on the guidelines established by NK for onboard CO2 capture and storage systems. This approval indicates that Mitsubishi Shipbuilding's design has passed the rigorous scrutiny of safety and operational requirements, lending credibility to the launch of the OCCS technology.

Mitsubishi Heavy Industries' CO2 Capture Technology

Mitsubishi Heavy Industries has a long-standing history of developing cutting-edge CO2 capture technologies since its collaboration with Kansai Electric Power Co., Inc. began in 1990. As of April 2025, the company has delivered 18 plants utilizing these advanced technologies. An upgraded version of their amine absorption liquid, KS-21™, is featured in the Advanced KM CDR Process™, exhibiting superior regeneration efficiency and lower emissions compared to its predecessor, KS-1™. This technology suite promises enhanced energy performance and operational cost reductions, further solidifying Mitsubishi's leadership in the CO2 capture sector.

For more information on Mitsubishi Heavy Industries' CO2 capture technologies, visit their official website.

Connect with Mitsubishi Heavy Industries

For further details about their innovations, you can check their official website at Mitsubishi Heavy Industries or follow their online magazine, SPECTRA. They are also active on social media platforms; you can find them on X (formerly Twitter) under the handle @MHI_GroupJP and on Instagram as @mhi_groupjp.

Topics Energy)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.