Innovative Real-Time Monitoring System for Vertical Accuracy in Ground Improvement Work

Introduction

In a groundbreaking collaboration, Furuno Electric Co., Ltd. and Takenaka Corporation have unveiled a new vertical accuracy real-time monitoring system that harnesses waveguide LAN technology. This innovative system aims to elevate the quality of ground improvement construction, essential for ensuring the stability of structures built on varying soil conditions.

Overview of the System

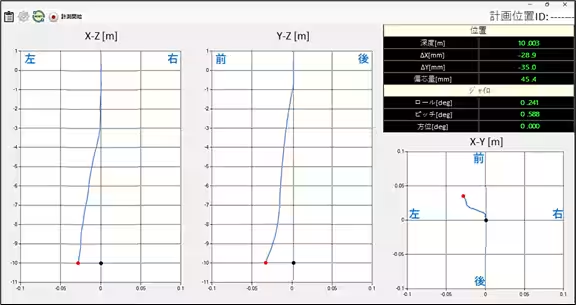

The vertical accuracy real-time monitoring system has been uniquely developed for deep mixing treatment methods. Traditionally, monitoring the actual drilling position of the excavation rods underground has posed significant challenges, making real-time tracking nearly impossible. However, this new system overcomes those limitations by effectively measuring and displaying the position of the drill tip in real-time.

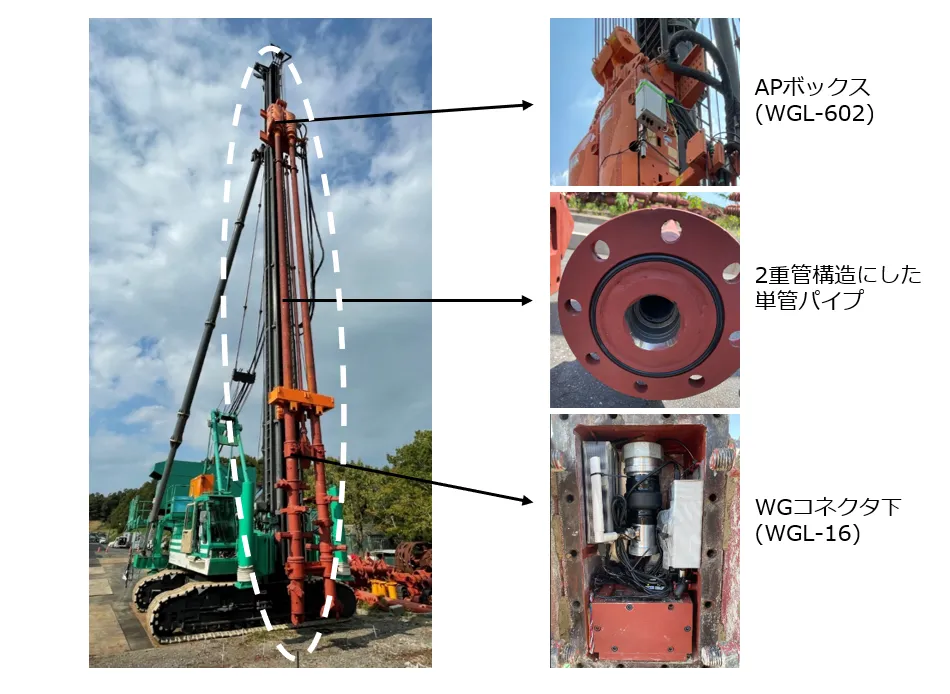

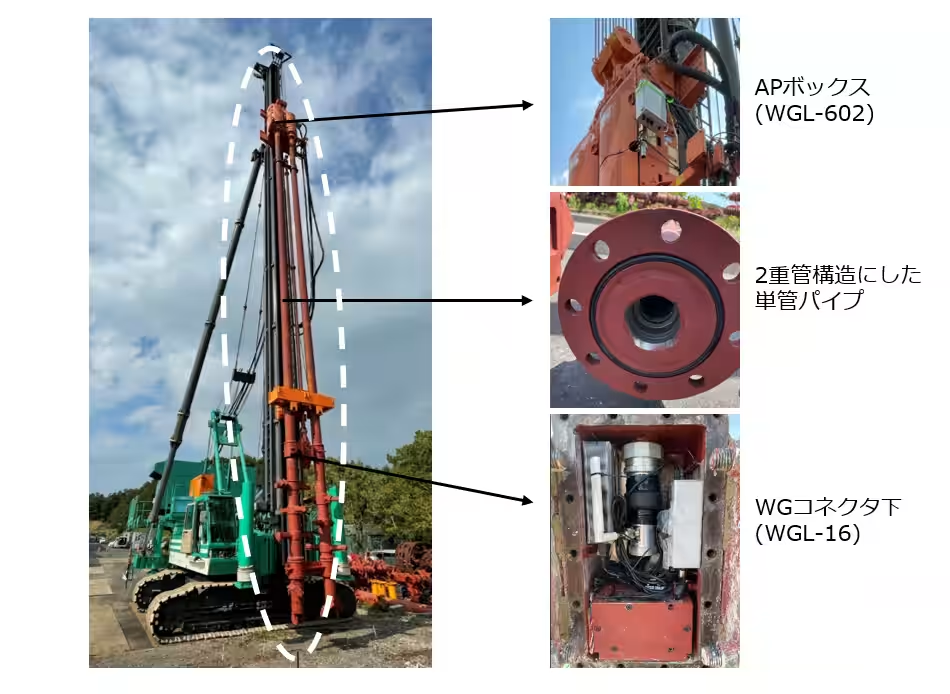

Implementation of Waveguide LAN

The system incorporates a waveguide LAN, installed at the center of the excavation rod, which connects to a gyroscope sensor located near the excavation site. This robust connection allows data to relay to a construction management PC, presenting the real-time position of the drill tip while simultaneously providing depth information. This real-time data enables construction teams to maintain high vertical accuracy, essential for creating quality ground improvements. Additionally, the innovative use of a dual-pipe structure protects the single-pipe sections with a pressure-resistant casing, ensuring stable wireless communication underground where traditional signals may falter.

Historical Context and Technological Milestones

Furuno Electric has long been recognized for its significant contributions to construction technology, particularly in providing wireless LAN environments in challenging locations such as high-rise buildings and underground facilities. The partnership with Takenaka Corporation to apply waveguide LAN technology further solidifies their commitment to enhancing the reliability and quality of ground improvement projects.

Evidence of Effectiveness

Recent trial runs employing a two-axis deep mixing treatment machine demonstrated that the measurement technology of this system performs well and meets practical usage standards. Previous methods of vertical accuracy management typically involved measuring the verticality from above ground, relying heavily on subjective judgments based on operator experience. With this new system, direct measurements of the excavation position can be made in real-time, offering an objective and highly accurate solution for maintaining vertical accuracy during construction.

Future Prospects

Furuno Electric aims to continue developing this monitoring system to contribute to the enhancement of construction quality and the dependability of ground improvement projects. The ability for precise, real-time data collection is expected not only to improve operational efficiencies but also to ensure the lasting stability of structures built on altered or reinforced soil.

Related Links

- - Waveguide LAN Series for Construction Sites

- - For inquiries regarding this system, please visit the Construction DX Contact Form.

Understanding Ground Improvement

Ground improvement methods like deep mixing involve injecting cement-based materials into the original ground, mechanically mixing and stirring it to create columnar or wall-like structures. This process is essential for reinforcing and stabilizing soil, making effective monitoring crucial for its success.

Conclusion

Furuno Electric, established in 1951, has maintained a pioneering position in sonar technology and electronic devices. The launch of this innovative monitoring system signifies another step in their journey towards enhancing construction methodologies worldwide, reinforcing their status as a global leader in marine electronics and construction technologies.

Topics Heavy Industry & Manufacturing)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.