Revolutionizing Rubber Quality Control with HACARUS Check AI Solution

Transforming Rubber Product Inspection with HACARUS Check

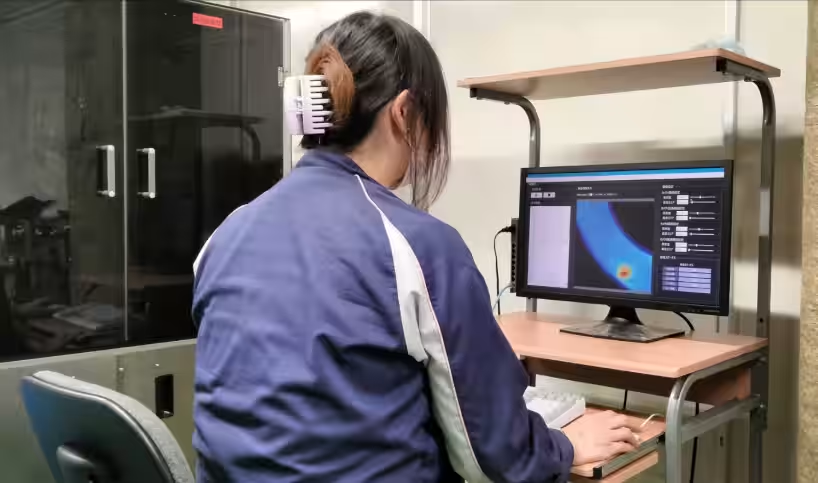

In a significant advancement in the field of rubber manufacturing, HACARUS, a Kyoto-based company, has successfully implemented its AI visual inspection software, "HACARUS Check," at Osaka Takenaka, specialized in rubber products. This partnership aims to enhance the quality control processes by enabling complete automated inspections of black rubber packing, an area historically known for its inspection challenges due to difficulties in detecting black spots and scratches on the products.

Background and Challenges

The manufacturing sector, especially in contexts dealing with black rubber products, faces considerable hurdles when it comes to visual inspections. Common issues include the inability to accurately detect surface irregularities like black spots or scratches. With a growing shortage of skilled labor, Osaka Takenaka sought to reduce the burden of manual inspections by introducing a rule-based image inspection solution. However, traditional threshold settings proved inadequate for addressing variations caused by rubber properties or mold conditions, failing to eliminate the risk of defective products completely.

To tackle these challenges, Osaka Takenaka turned to AI technology to introduce "HACARUS Check," which offers a solution capable of adapting to variations in manufacturing conditions and identifying hard-to-detect defects.

Achievements with HACARUS Check

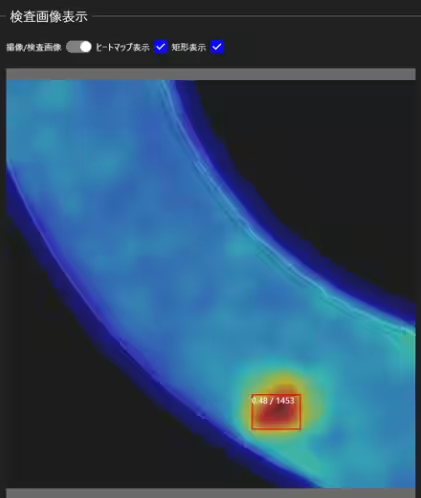

The introduction of "HACARUS Check" has led to remarkable improvements in the inspection processes for black rubber packing. This sophisticated software utilizes a unique good-image learning mechanism that enables it to identify defects by comparing products against images of defect-free items. By establishing stricter thresholds aimed at preventing the outflow of defective products, any flagged items receive secondary inspections, solidifying a comprehensive inspection protocol.

Adapting to Product Variations

Given the nature of rubber products, variations in appearance can occur based on manufacturing conditions, leading to fluctuations in yield rates. HACARUS Check facilitates on-site re-learning, allowing operators to promptly adjust quality control measures in just a few minutes. This capability means that inspections can be continuously refined to adapt to any changes in the visual characteristics of quality products, ensuring effective and flexible operational processes are maintained.

Future Prospects

The successful integration of "HACARUS Check" with existing image inspection systems marks a crucial step towards automating the inspection of black rubber products. Nevertheless, numerous products exhibit defect characteristics that can escape human detection, as changes like discoloration may obscure issues. Additionally, the rise of more complex product shapes underscores the necessity for creating optimal imaging environments.

Looking ahead, HACARUS envisions responding to these ongoing challenges by developing comprehensive inspection solutions, including advancements in imaging procedures. Collaborative projects aimed at pushing the boundaries of quality control are expected to emerge in response to the evolving manufacturing landscape.

About Osaka Takenaka

Founded in December 1947 and located in Osaka, Osaka Takenaka specializes in producing and selling parts for gas meters and rubber products. Under the leadership of President Daisuke Sumitomo, the firm has established a solid reputation in the industry. For more information, visit Osaka Takenaka.

About HACARUS

HACARUS is committed to fostering the future with its mission of providing next-generation AI solutions that transform data utilization. Since its establishment in 2014, the company has substantially contributed to various businesses by streamlining operations through minimal data requirements while leading to impactful problem resolutions. With a focus on facilitating efficient collaboration between humans and AI, HACARUS supports clients from data acquisition to seamless integration with existing systems. The head office is located in Kyoto. For more details, visit HACARUS or contact their press team at [email protected].

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.