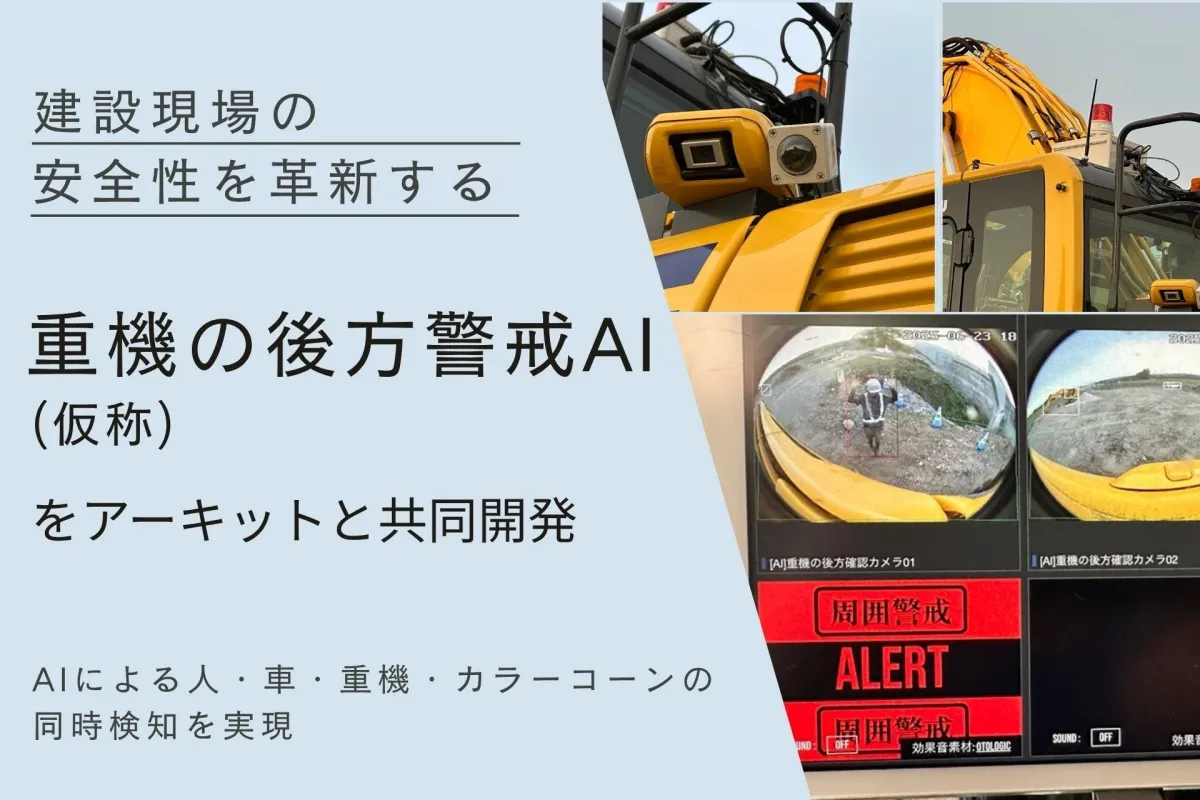

Hagiwara Construction Implements AI Technology for Enhanced Site Safety with Heavy Machinery

Revolutionizing Construction Site Safety with AI

Hagiwara Construction Industry Co., Ltd., located in Obihiro City, Hokkaido, in partnership with Archit LLC, has embarked on a groundbreaking project aimed at enhancing safety at construction sites. Their joint venture has led to the development of a novel system known as the "Heavy Machinery Rear Warning AI (provisional name)." This innovative AI technology is designed to detect people, vehicles, heavy machinery, and even traffic cones simultaneously, tackling the longstanding issue of contact accidents on job sites.

Background of the Development

Historically, proximity detection systems in construction environments relied heavily on IC tags for detecting workers and the use of backup cameras for identifying human presence. However, these conventional methods often fall short, leading to the potential for missed detections, especially concerning workers without IC tags. Moreover, the risk of collision between vehicles and heavy machinery poses a significant safety concern. Recognizing these challenges, Hagiwara Construction decided to enhance safety measures in a more practical and comprehensive manner by collaborating with Archit in the pursuit of a cutting-edge AI system.

System Overview and Features

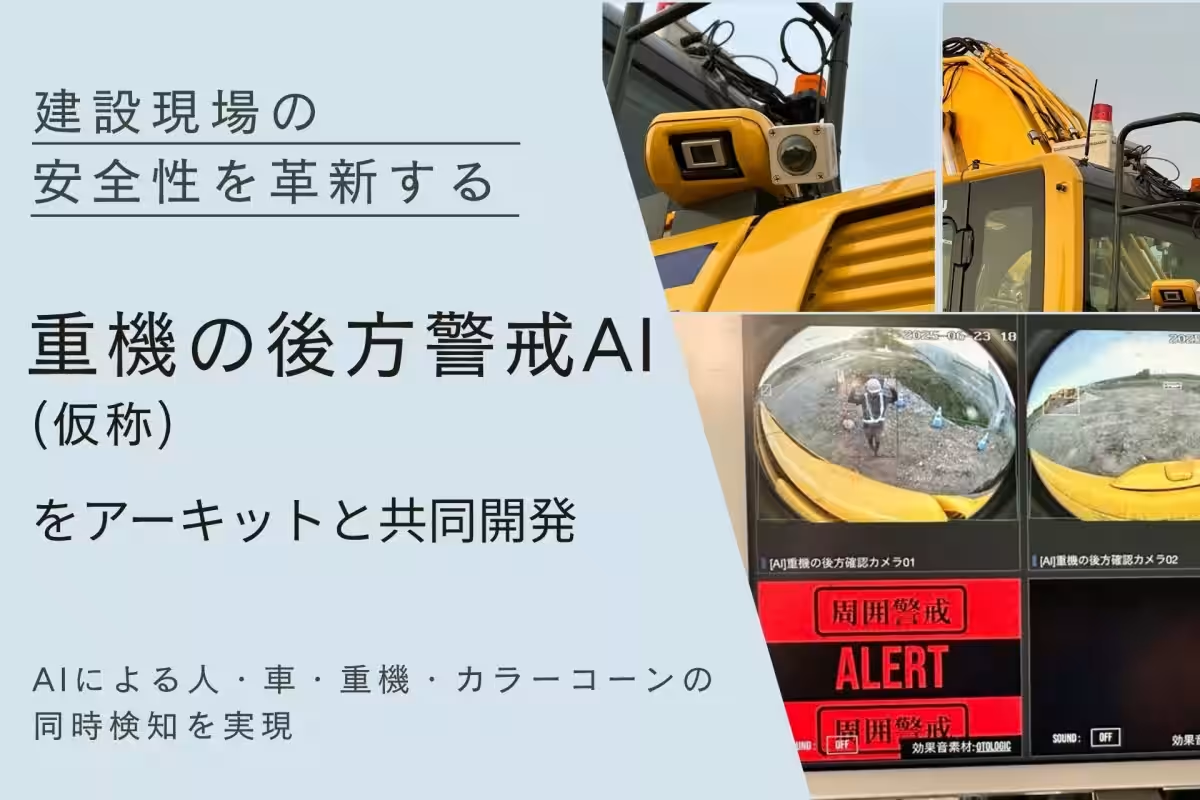

The "Heavy Machinery Rear Warning AI (provisional name)" integrates a wide-angle camera setup at the rear and sides of heavy machinery. This advanced system uses AI to analyze real-time footage from these cameras, automatically detecting and alerting operators to any objects entering blind spots. Signals are communicated through a monitor installed in the driver's cabin, flashing warning lights on the machinery, and external displays, allowing both the operator and any personnel nearby to receive timely notifications.

Key Features:

- - Comprehensive Blind Spot Coverage: The wide-angle cameras installed at the back and side of heavy machinery eliminate dead zones.

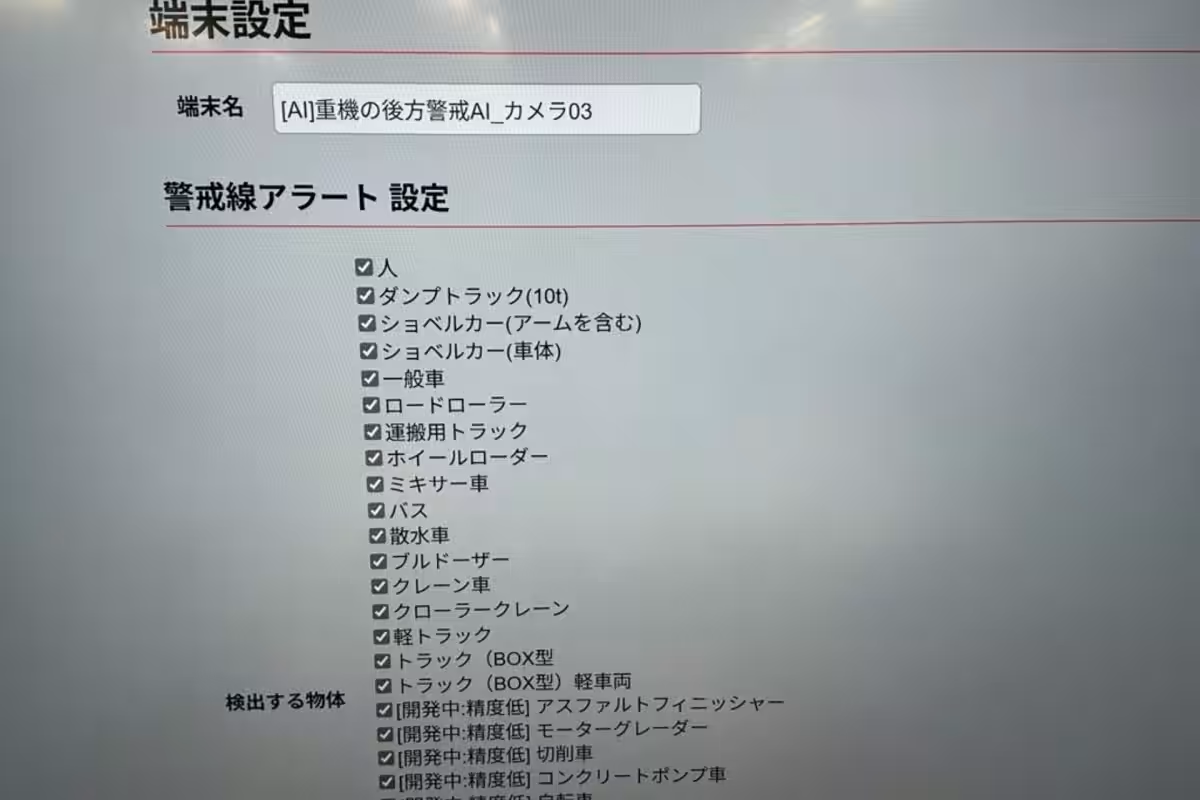

- - AI Detection: The system employs image analysis to recognize people, vehicles, heavy machinery, and colored cones in real-time.

- - Instant Alerts: When any detected object enters the designated area, a warning signal is activated through external lights.

- - Monitor Display: Detection status can be readily displayed on both the driver’s monitor and external screens.

- - Flexible Detection Settings: Users can easily customize detection parameters through a user-friendly interface.

In addition, the system incorporates proprietary AI technology that can learn and adapt to the specific needs of various job sites, making it increasingly versatile.

Future Developments

The team at Hagiwara Construction is currently preparing to apply for registration with NETIS (New Technology Information System) and aims for practical implementation by 2025. The company remains committed to developing technologies that enhance safety and contribute positively to the overall improvement of working conditions in the construction industry.

Insights from the Development Team

Commenting on the project, Masahiro Takayama, General Manager of the Digital Promotion Division at Hagiwara Construction, mentioned, "Our goal has always been to create realistic safety solutions that are practical for daily use on-site. We have collaborated closely with Archit to develop this system, focusing on enhanced safety levels. The previous systems have heavily relied on sensors and IC tags, which may not adequately detect individuals who unexpectedly enter the work area without these safety devices.

Moreover, our newly developed AI system is capable of identifying not only people but also a wide range of objects present on-site, showcasing its high versatility. As we continue to train the AI, we expect the detection capabilities to expand, leading to further advancements. With the anticipated evolution of automatic and remote construction techniques, there is a growing risk of fewer workers on-site, increasing the probability of accidents between machinery, vehicles, and other equipment. In such scenarios, we believe this system will serve as an effective solution."

Hagiwara Construction's proactive approach to safety reflects a significant step forward in bridging the gap between technology and occupational safety within the construction industry.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.