Introducing the Knight Checker: A Revolutionary AI Visual Inspection System

T-Net Japan Launches AI Visual Inspection System 'Knight Checker'

T-Net Japan, led by CEO Yasuki Kimoto, has launched the 'Knight Checker,' an AI visual inspection system, as of October 1. This innovative solution is part of their digital transformation support tool, 'Naksa Knight,' which aims to alleviate challenges in manufacturing and logistics sectors.

The introduction of Knight Checker promises to tackle traditional obstacles associated with implementing AI visual inspection systems:

1. High Costs

2. Long Lead Times

3. Difficulty in Acquiring Training Data for AI Models

By addressing these key pain points, Knight Checker aims to accelerate the integration of AI visual inspections in operational environments, ultimately contributing to resolving labor shortages. For more details, explore the DX solution site or the Knight Checker service page.

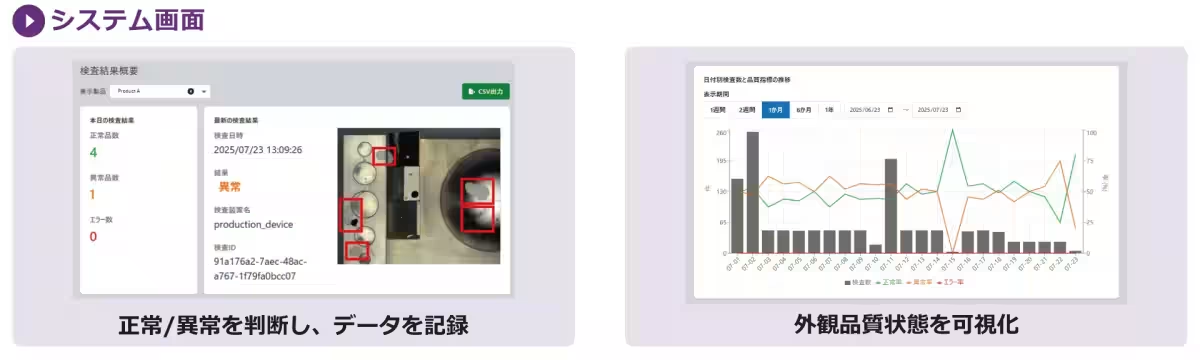

Key Features of Knight Checker

1. Cost-Effective Implementation

Traditional AI visual inspection systems often required custom development for each site, leading to increased costs and longer implementation timelines. Knight Checker innovates by offering a packaged solution that includes all essential features for AI visual inspections. This pre-configuration significantly shortens the development period, enabling T-Net Japan to deliver services at a reduced cost and in a shorter timeframe.

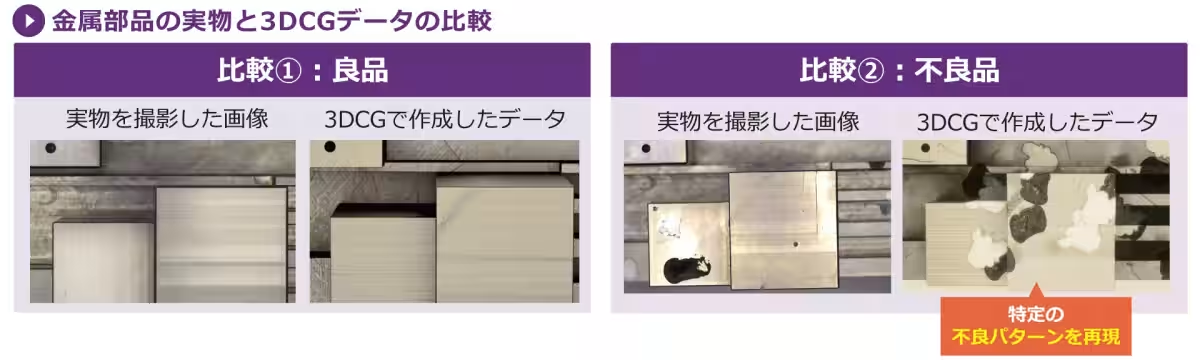

2. Rapid Deployment and Easy Data Acquisition through Digital Twin Technology

One of the primary hurdles in deploying AI models is the collection of image data of both good and defective products. Knight Checker leverages 3D CGI technology to create hyper-realistic digital twin data, facilitating the AI model's training process. This allows for a drastic reduction in the duration of the training phase. In addition, the system is capable of reproducing potential defects, such as scratches, chips, and painting errors, thus preparing for inspections of defects that have yet to occur at the site.

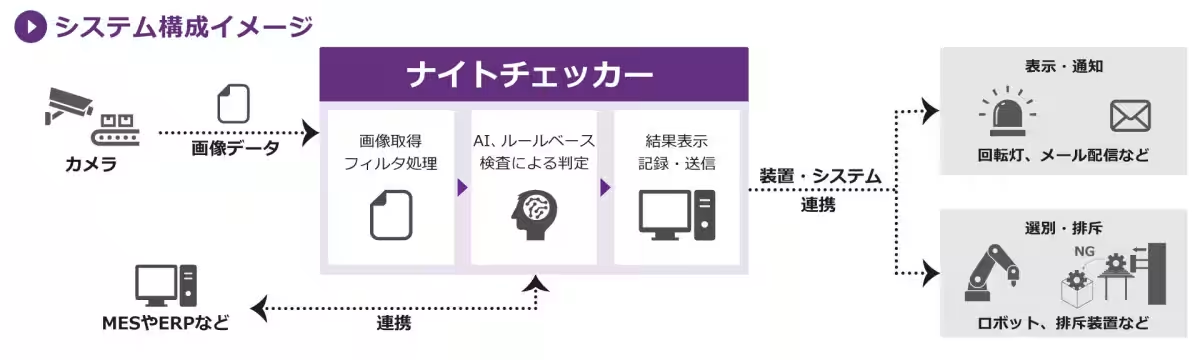

3. Flexible System Integration

Knight Checker allows for seamless integration with existing factory equipment, including cameras installed on production lines, sorting devices for classifying products as 'OK' or 'NG,' as well as notification systems using lights, monitors, and email alerts. Furthermore, it interfaces with higher-level systems like MES and ERP, ensuring a smooth installation leveraging current factory resources.

Upcoming Webinar

T-Net Japan will host a free online seminar on October 8, 2025, from 1:00 PM to 2:00 PM via Zoom. Interested participants can register through the webinar page.

What is Naksa Knight?

Naksa Knight is a digital transformation support solution offered by T-Net Japan, combining over 20 years of expertise in production technology and system development. It addresses prevalent challenges in manufacturing and logistics with a suite of seven solutions, explained in an accessible manner using the character 'Knight' to symbolize problem-solving.

About T-Net Japan

Since its founding, T-Net Japan has developed a unique portfolio of diverse technologies and knowledge across various business sectors. The company has thrived in areas such as customer support services, system development, outsourcing technical expertise, plant engineering, industrial machinery design, conveyor system manufacturing, and the production and sale of industrial air conditioning units.

- - Company Name: T-Net Japan, Inc.

- - CEO: Yasuki Kimoto

- - Headquarters: 930-10 Nariai-cho, Takamatsu City, Kagawa, 761-8081, Japan

- - Tokyo Office: 18F Blue Front Shibaura Tower S, 1-1-1 Shibaura, Minato-ku, Tokyo, 105-0023, Japan

- - Established: April 1976

- - Corporate Website: T-Net Japan

- - DX Solution Site: Smart Factory

- - Knight Checker Page: Knight Checker

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.