Kumamoto Rocky's Collaboration on AI Demand Forecasting to Reduce Food Waste

Kumamoto Rocky's Innovative Approach to Tackling Food Waste

In a groundbreaking initiative, Kumamoto Rocky, a supermarket chain based in Kumamoto, Japan, has partnered with Synops Inc., along with other industry players, to implement an AI-powered demand forecasting system. This project aims to combat food waste, a pressing issue impacting the Japanese food industry. The initiative is part of the Ministry of Agriculture, Forestry, and Fisheries' urgent model support project for reducing food loss during the fiscal year 2024.

The Challenge of Food Waste in Japan

Every year, Japan generates about 4.64 million tons of food waste, of which nearly 2.31 million tons comes from businesses. Tackling such a massive problem requires not just surface-level fixes, like discounts and food drives, but also a fundamental overhaul of the supply chain. This is where innovative demand forecasting technologies come into play.

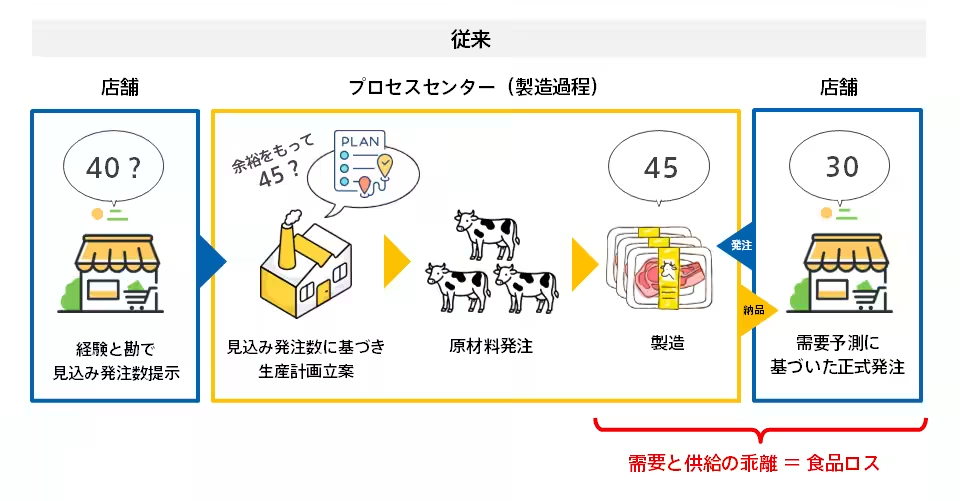

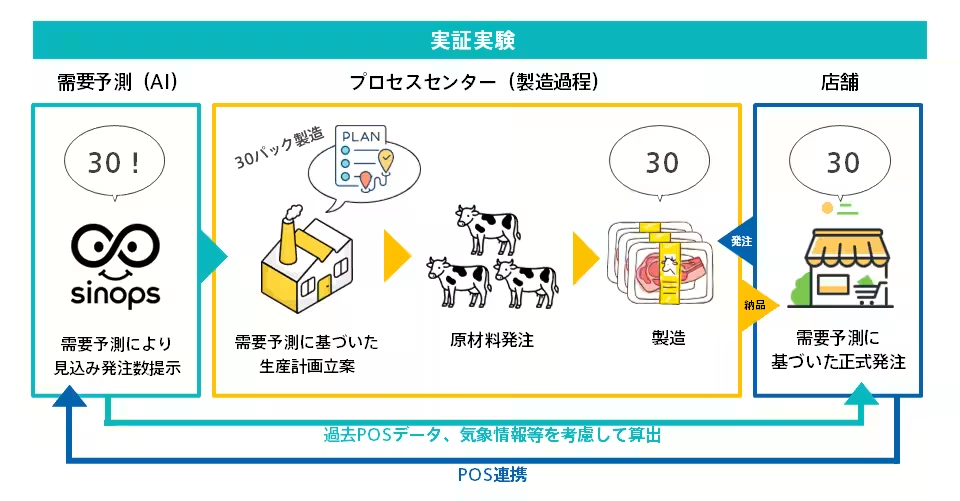

Traditionally, food retail operations have relied heavily on manual forecasting, which often leads to overstocking and food wastage. In attempting to improve efficiency and reduce waste, Kumamoto Rocky aims to utilize Synops' AI-driven demand forecasting service, known as "sinops-R," to optimize their meat procurement and manufacturing planning processes while integrating dynamic pricing strategies.

The Implementation Phase

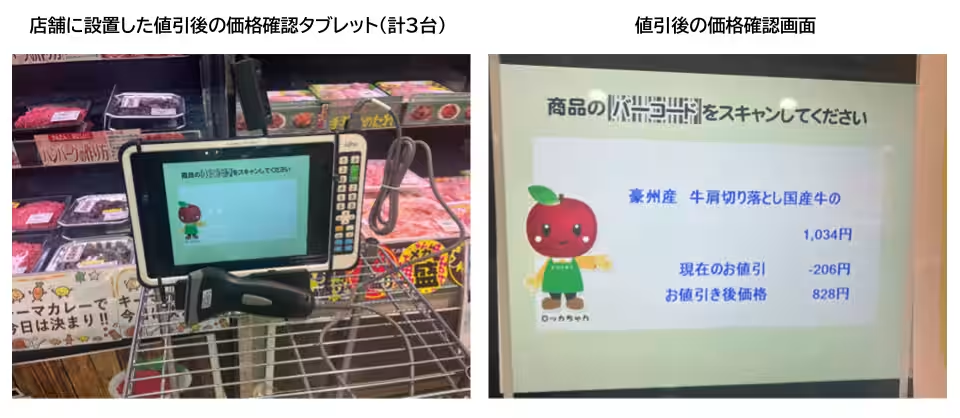

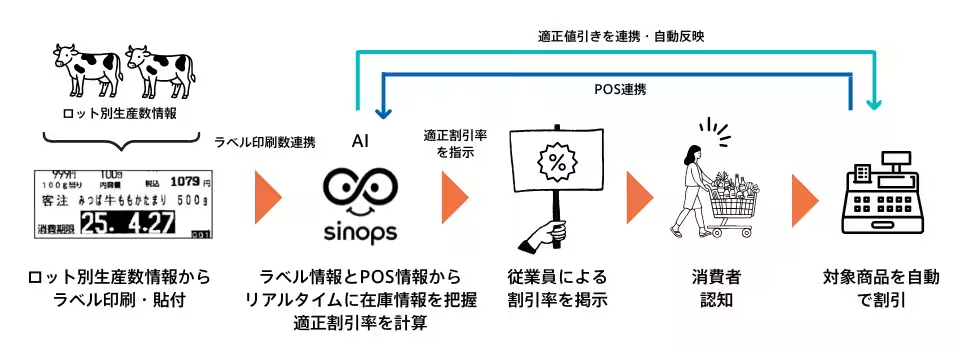

The proof-of-concept experiment will run from April to October 2025, during which Rocky will utilize the service to streamline their meat supply chain operations. The implementation involves collaboration with other companies, including R-Meat, Solimachi Giken, and Nishinippon Ishida. Together, they aim to assess and optimize various components of the supply chain, from procurement to pricing strategies that consider product expiration dates.

Results Expected

Preliminary estimates predict a decrease in manufacturing stage food waste by approximately 3.0%, translating to a substantial monetary saving of 44 million yen (about $400,000). In the retail phase, the dynamic pricing strategy is anticipated to reduce waste by 1.3 percentage points and cut down labor involved in markdowns by an impressive 83.3%, further projecting savings of 99 million yen ($900,000).

This dual approach not only promises to improve food loss metrics but is also designed to enhance operational efficiency across both the manufacturing and sales sides of the business.

Collaborative Efforts and Contributions

Each participant in this initiative plays a distinct role:

- - Kumamoto Rocky: Facilitates the execution of the proof-of-concept and provides crucial data.

- - Synops: Supplies the AI demand forecasting technology and conducts simulations to refine the process.

- - R-Meat: Aids in planning manufacturing schedules aligned with demand forecasts.

- - Solimachi Giken: Delivers the Point of Sale (POS) systems and facilitates data integration across partners.

- - Nishinippon Ishida: Supplies the production instruction system and manages the printing of necessary labels.

What's Next?

Based on the outcomes of this experiment, Kumamoto Rocky plans to extend the implementation of the sinops demand forecasting system beyond meat to other areas within its 28-store network. Future efforts will also explore predictive purchasing for raw materials and aim for further reductions in food waste and operational costs.

About the Companies Involved

Kumamoto Rocky Co., Ltd.

Founded in Kumamoto Prefecture, Kumamoto Rocky has built a reputation as a leading supermarket chain known for its factory-direct management of fresh food products, eliminating in-store processing. The company prides itself on its extensive partnerships with pharmaceutical wholesalers and strives to enhance local food supply chains, ensuring availability even during emergencies.

Synops Inc.

Synops is driven by its mission to reduce global waste by 10% through its innovative self-ordering service. Their technology is particularly effective in managing products with shorter shelf lives, such as dairy and prepared foods, and continues to be adopted widely across the retail sector.

Solimachi Giken Co., Ltd.

Since its establishment, Solimachi Giken has focused on standardizing Point of Sale systems for retail businesses, pushing for industry innovation and contributing significantly to the retail landscape in Japan.

Nishinippon Ishida Co., Ltd.

A leading weighing equipment manufacturer, Nishinippon Ishida offers comprehensive solutions in packaging, logistics, and system services across the food manufacturing and retail industries, backed by a commitment to technological advancement.

Through this collaborative approach, tackling the issue of food waste in Japan takes a significant step forward, and the anticipated results from this experiment may set a new standard in the retail industry.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.