Revolutionizing Waveguide Connection Evaluation with AI-Driven Automation

Automating Waveguide Connection Evaluation with AI

Researchers at the National Institute of Advanced Industrial Science and Technology (AIST) have pioneered a groundbreaking technique using machine learning to automatically assess the connection state of waveguides used in high-frequency electromagnetic wave measurements, ranging from millimeter waves to terahertz frequencies. This innovative approach offers an efficient solution to the traditional reliance on manual evaluations, which had led to discrepancies in measurement accuracy due to subjective human judgment.

Understanding Waveguides and Their Importance

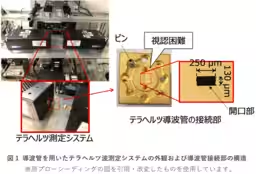

Waveguides are essential components for efficiently transmitting electromagnetic waves in a specific direction. With the rapid advancements in communication technologies focusing on millimeter and terahertz wave ranges, numerous electronic devices incorporating these frequencies have been developed. High-quality measurements of these devices necessitate precise connections between electronic parts and waveguides to evaluate their transmission and reflection characteristics accurately. However, the conventional method of visually inspecting these connections has significant limitations, often varying by technician and leading to unreliable measurements.

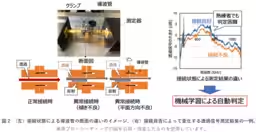

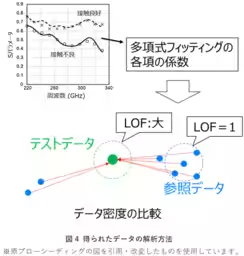

The new system leverages data collected from measurements that fluctuate based on the waveguide connection's state. By utilizing AI, specifically machine learning, the researchers have developed a method that can autonomously determine whether the connections are good or faulty, thereby enabling consistent and highly accurate assessments across various devices and configurations. This represents a substantial improvement over previous methods, promising enhanced utilization of terahertz technologies in both research and industrial applications.

Enhancing Measurement Precision with AI

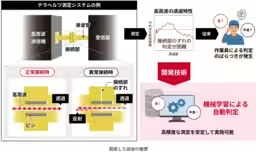

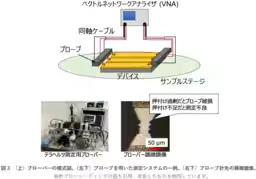

In the context of millimeter-wave and terahertz technologies, the accuracy of measurements is heavily influenced by the positioning of waveguides. Small misalignments, often just a few micrometers, can significantly alter measurement outcomes, but these imperfections can be challenging to detect with the naked eye. The new system addresses this issue by employing machine learning to analyze measurement data from waveguide connections, identifying subtle variations in signal characteristics that indicate the quality of connections.

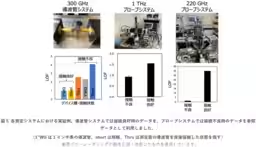

Historically, the assessment of waveguide connections relied on skilled technicians. However, this new approach democratizes the process, allowing even those with minimal experience to conduct high-precision measurements in a repeatable manner. The research team validated the automatic classification by comparing the original measurement data against known reference points, ultimately demonstrating the system’s capability to assess various waveguide configurations without human intervention.

The Need for Reliable Measurement Techniques

The urgency for reliable evaluation methods has been magnified by the escalating development of next-generation technologies such as 6G communications and terahertz scanners. High-frequency devices, now more common, incorporate various components, each requiring meticulous testing to ascertain their operational efficacy. Given the increasing number of engineers engaging in high-frequency measurements, the demand for standardized, efficient testing environments has surged.

This research by AIST addresses this demand directly, providing a unique solution that not only simplifies the measurement process but also elevates its accuracy, thus enhancing the overall reliability of results. The detailed aspects of this innovation are set to be unveiled at the upcoming IEEE MTT-S International Microwave Symposium (IMS) 2025, scheduled for June 15-20 in San Francisco, USA.

Future Directions and Automation

The future scope of this technology entails the automation and autonomy of measurement system setups, integrating the connection state assessment with motorized alignment systems for waveguides. The anticipated outcome is a fully automated, self-setting device setup, boosting the trustworthiness of millimeter and terahertz evaluation systems while contributing to the broader automation trend in manufacturing.

This move toward automation could significantly reduce costs associated with sophisticated high-frequency equipment management by minimizing the need for extensive technical expertise in setups. As a result, the transition from traditional reliance on skilled technicians to automated systems will likely accelerate the development of next-generation high-frequency technologies essential for the future.

In summary, the integration of artificial intelligence into waveguide connection evaluation not only promises enhanced measurement precision but also positions researchers and industries alike to more effectively tackle the challenges posed by evolving high-frequency technologies. The implications of this research stretch far beyond mere testing, potentially revolutionizing entire fields reliant on accurate electromagnetic wave measurement.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.