NEC Facilities Shortens Proposal Period for Water Recovery Services to Two Weeks

NEC Facilities Innovates Water Recovery Proposal Process

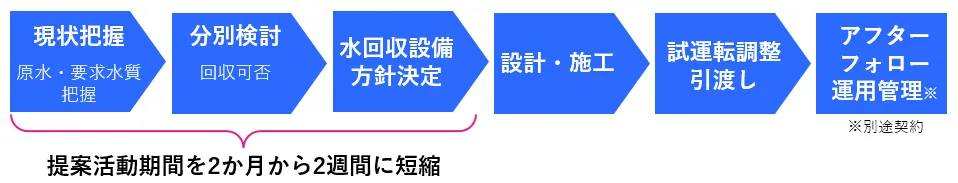

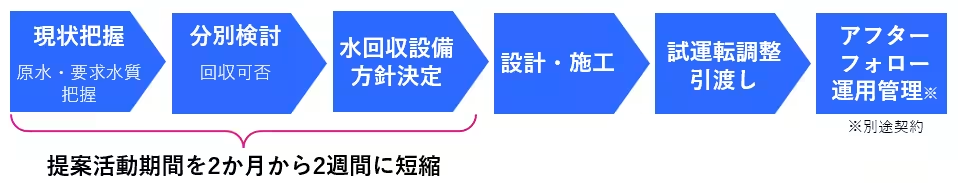

NEC Facilities, headquartered in Minato, Tokyo, has recently made a significant advancement in its Water Recovery Services aimed at promoting the reuse of factory water. The company has introduced a new system that allows real-time visualization of water usage, including well water and river water utilized in manufacturing processes. This innovation is set to revolutionize the proposal timeline, cutting it down from roughly two months to just two weeks.

Background

In recent years, businesses have increasingly recognized water-related risks as pressing management issues. Factors such as stricter wastewater treatment regulations, rising water costs, and water scarcity due to climate change have heightened this awareness. Leveraging decades of experience in managing semiconductor and LCD factories, NEC Facilities has been providing services focused on reducing wastewater loads through efficient water reuse.

The Water Recovery Service analyzes the overall water usage within a factory, identifies suitable wastewater systems for reclamation, and proposes the installation of equipment that allows for efficient water circulation between manufacturing processes. Additionally, this service aligns with one of the Sustainable Development Goals (SDGs) aimed at ensuring safe water and sustainable management practices. It is also expected to help minimize costs associated with water extraction and wastewater discharge.

Historically, calculating reuse rates and cost-saving potential required one to two months of work by skilled technicians. However, in a bid to expedite the proposal process and facilitate decision-making for clients, NEC Facilities developed this innovative system as part of its ongoing digital transformation (DX) initiatives.

Features of the New System

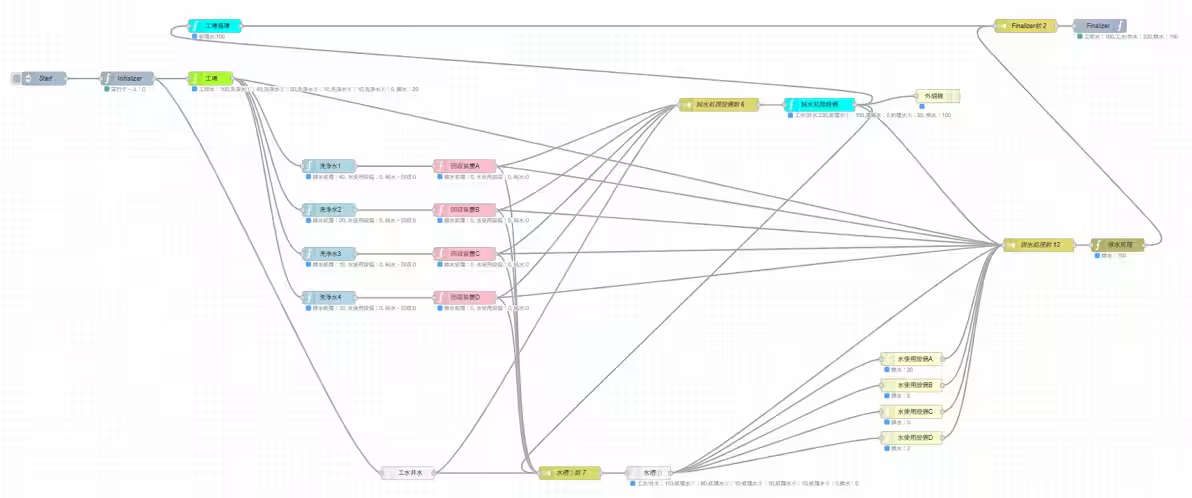

The newly developed system enables technicians to visualize the water flow and reuse quantity used in manufacturing processes right after they gather initial information from clients. The main features of the system include:

1. Real-Time Simulation of Water Usage and Savings

Technicians can input data regarding water usage, allowing for instantaneous visualization of water flow and reuse across the factory. By simulating various scenarios, the system provides real-time display of reclaimed water rates as well as costs associated with water extraction and discharge. This significantly reduces the time required to explore efficient water utilization methods.

2. Utilization of Expert Knowledge

With years of experience in semiconductor and LCD facilities management, NEC Facilities has accumulated substantial knowledge regarding environmental equipment. By integrating the insights of seasoned technicians into the system, uniform quality analyses of current site conditions can be executed efficiently.

3. Improved Water Recovery Rates as Risk Mitigation

The ability to control extraction and discharge costs can directly address challenges faced by industries where water management is crucial, such as semiconductor and electronic parts manufacturing, which are susceptible to land subsidence, extraction limitations, and discharge regulations.

Future Developments

Looking ahead, NEC Facilities plans to focus its Water Recovery Services primarily on manufacturing industries that utilize large quantities of water, such as semiconductor and electronic component factories. The company aims to accelerate its proposals, particularly in regions with high water-related risks. Ultimately, NEC Facilities envisions a nationwide expansion, positioning itself as a partner in enhancing water security while supporting clients in realizing sustainable factory management and addressing societal challenges.

Through these innovations and commitments, NEC Facilities demonstrates its dedication to leading the charge towards a more sustainable and efficient future for industrial water management.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.