Revolutionary Media Shape for Ball Mills: Beyond the Sphere to Boost Efficiency

Innovative Shape for Ball Mill Media

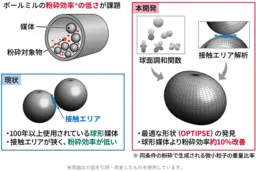

Recent research led by Takao Ueda, a senior researcher at the National Institute of Advanced Industrial Science and Technology (AIST), has unveiled a new media shape designed to improve the efficiency of ball mills. Traditionally, the round shape of the media used in these machines has remained unchanged for over a century, despite efforts to enhance the grinding process.

The Quest for Efficiency

Ball mills are cylindrical devices that use spherical media to grind materials, yet they operate with a remarkably low energy efficiency of less than 1%. This means most of the energy input is wasted as heat or vibration, a significant concern given that mineral processing can account for about 2% of global energy consumption. Despite numerous attempts to replace spherical media with non-spherical forms, previous innovations failed to yield substantial improvements.

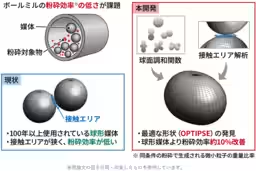

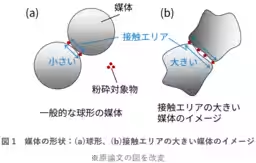

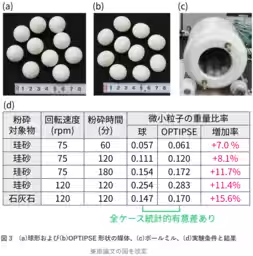

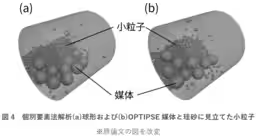

Through the application of spherical harmonic functions, Ueda and his team generated approximately 5,500 unique three-dimensional shapes. The most effective shape designed with improved gripping capabilities is known as OPTIPSE, which resembles an irregularly flattened ellipsoid.

Experimental Validation

Laboratory experiments using OPTIPSE-shaped alumina media demonstrated an increase in grinding efficiency by about 10% compared to traditional spherical media. The investigation involved direct comparison of particle size reductions when using both OPTIPSE and spherical shapes under identical conditions in a miniature magnetic mill. The results indicated that the OPTIPSE media consistently produced more fine particles, thus enhancing overall grinding efficiency.

How OPTIPSE Works

The unique design of OPTIPSE enable it to capture and pulverize more particles during operation. Simulations employing discrete element methods confirmed that this new shape interacts more frequently with the materials being processed, imparting greater impact forces, and resulting in a significant increase in effective grinding areas. This enhanced performance narrows the gap of energy loss, vastly improving operational efficiency and potentially leading to reduced energy requirements in industrial applications such as ore processing and cement manufacturing.

Future Developments

While the current OPTIPSE design produces higher manufacturing costs when created from machined alumina, using casting methods could streamline production and keep costs competitive with traditional shapes. As AIST moves towards practical industrial applications, plans are underway to collaborate with industry partners for real-world testing of OPTIPSE under actual operational conditions. Further research will also aim to refine the design process through contact area evaluations and advanced simulation techniques to discover even more effective shapes.

The detailed findings of this research project are set to be published in the Minerals Engineering journal on November 8, 2025. This could mark a significant turning point in ball mill technology, providing a pathway for improving energy efficiency in an industry that heavily relies on this established grinding technique.

Conclusion

The development of OPTIPSE marks a promising advancement in the field of mineral processing. By moving away from conventional spherical media, industries can unlock new levels of efficiency and resource management, making this innovative technology not only necessary but essential for sustainable progress.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.